Preparation method of novel polyether modified organic silicon defoamer

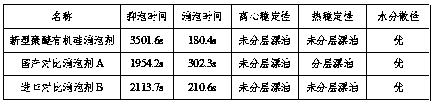

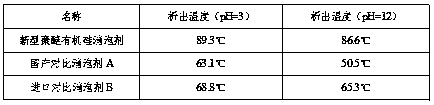

A technology of silicone defoamer and polyether-modified silicone oil, which is applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc. Good effect and other problems, to achieve the effect of excellent performance, good defoaming and anti-foaming performance, and short defoaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This embodiment provides a method for preparing a novel polyether modified silicone defoamer, comprising the following steps:

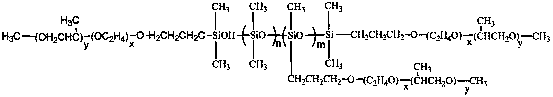

[0027] S1. Using tetramethyldihydrodisiloxane, octamethylcyclotetrasiloxane, and tetramethylcyclotetrasiloxane as raw materials, and using concentrated sulfuric acid as a catalyst to prepare double-end and side-chain hydrogen-containing silicone oils;

[0028] S2. Using 5 parts of the double-end and side-chain hydrogen-containing silicone oil and 1 part of allyl polyether as raw materials, grafting with 0.15 part of chloroplatinic acid as a catalyst to obtain a double-end and side-chain polyether modified silicone oil;

[0029] S3. Mix the double-end and side-chain polyether-modified silicone oil, silicone paste, and compound emulsifier, emulsify, add a thickener and stir to dilute after homogenization, and obtain a novel polyether-modified silicone defoamer. The compound emulsifier includes at least two kinds of Span-60, Span-80, and fatty alc...

Embodiment 1

[0034] Synthesis of double-end and side-chain polyether modified silicone oil:

[0035] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add metered 15 grams of tetramethyldihydrogendisiloxane, 300 g of octamethylcyclotetrasiloxane, 20 g of tetramethylcyclotetrasiloxane Siloxane and 3g concentrated sulfuric acid catalyst were stirred, heated to 45°C, and reacted for 5 h. After the obtained liquid is fully cooled, slowly add 9g of sodium carbonate powder to neutralize the sulfuric acid, adjust the pH to 6-7, and filter with a vacuum pump. Add 10 g of anhydrous magnesium sulfate to the obtained filtrate to dry, filter with suction, filter out the solid generated by neutralization, and obtain 322 g of a transparent product with a relative molecular mass of 3000 double-end and side chain hydrogen-containing silicone oil.

[0036]

[0037] In a 500 mL four-neck flask equipped with a stirrer, a thermometer, a nitrogen gas guide tube and ...

Embodiment 2

[0041] Preparation of silicone paste:

[0042] Add 50 g of 500mPa•s simethicone oil, 30g of 1500 mPa•s simethicone oil, 15 g of 1000mPa•s 107 glue, 10g of 5000mPa•s 107 glue, and 10 g of white carbon black in a 250mL three-necked flask , 12 g of methylvinyl MQ silicone resin, 4 g of potassium hydroxide, heating and stirring at 150 ° C for 3 h, and cooling down to room temperature to prepare a silicone paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com