Technology for attaching capacitive touch screens

A capacitive touch screen and lamination technology, which is used in electrical digital data processing, packaging/bundling items, lamination, etc., can solve the problem of affecting the quality of capacitive touch screens, high defective rate and production cost, and poor defoaming effect. and other problems, to achieve the effect of eliminating the edge pressure effect, improving the yield rate and good defoaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

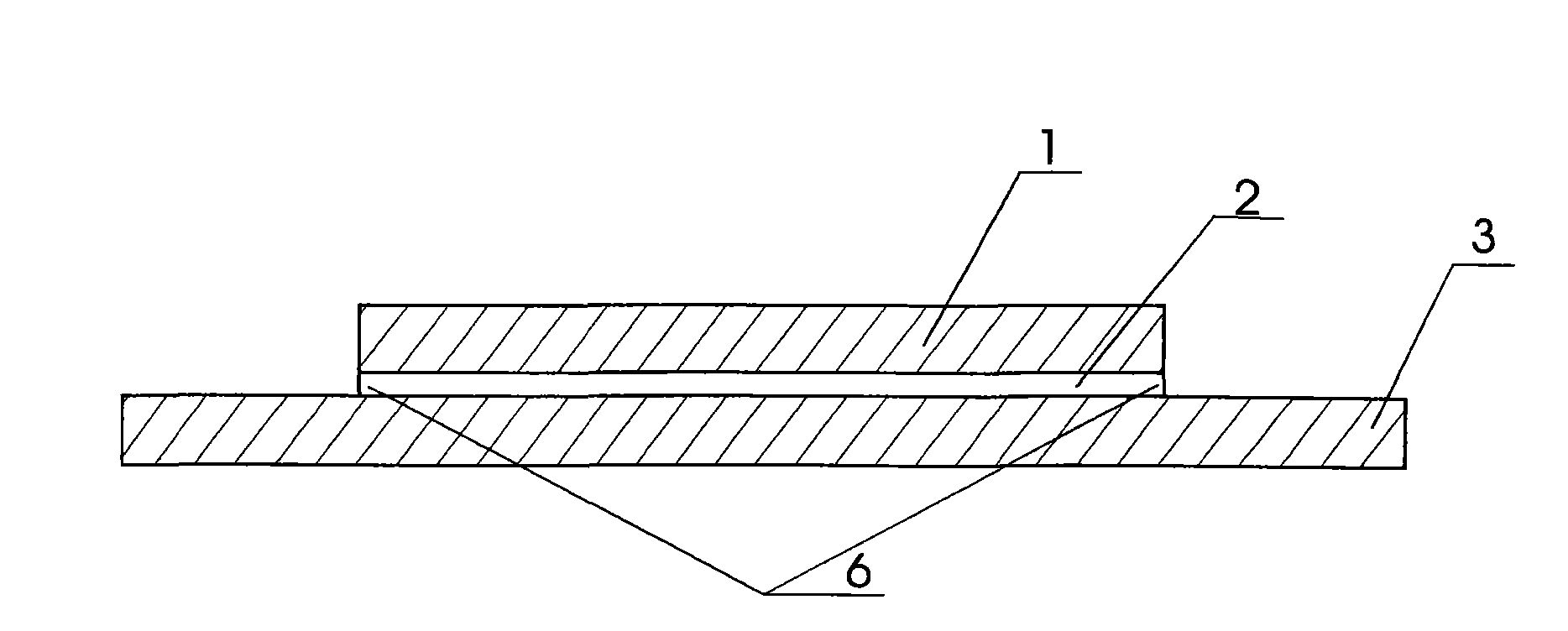

[0015] Embodiment 1: as figure 1 As shown, the specification of TP sensor 1: 85mm×55mm×0.5mm (length×width×thickness); the specification of tempered glass panel 3: 110mm×56mm×1.0mm; the thickness of optical glue 2: 175um.

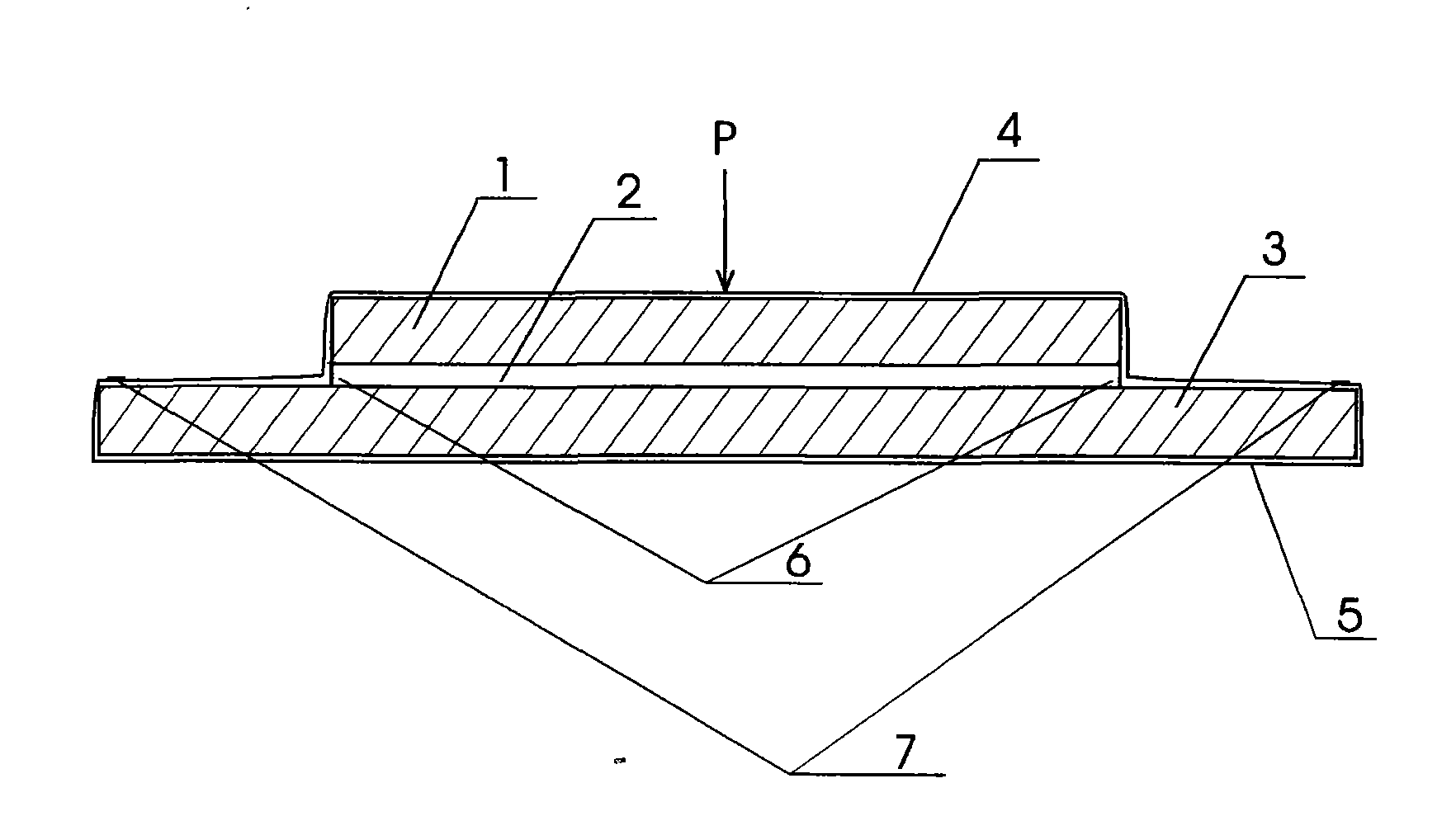

[0016] Such as figure 2 As shown, the micro-airbag is formed by bonding PVC film 4 and PET film 5, and P is the pressure of the central vacuum machine. The bonding edge 6 of the TP sensor and the tempered glass panel is moved outward to the edge 7 of the micro-airbag, which well eliminates the air bubbles on the bonding edge 6 of the TP sensor and the tempered glass panel.

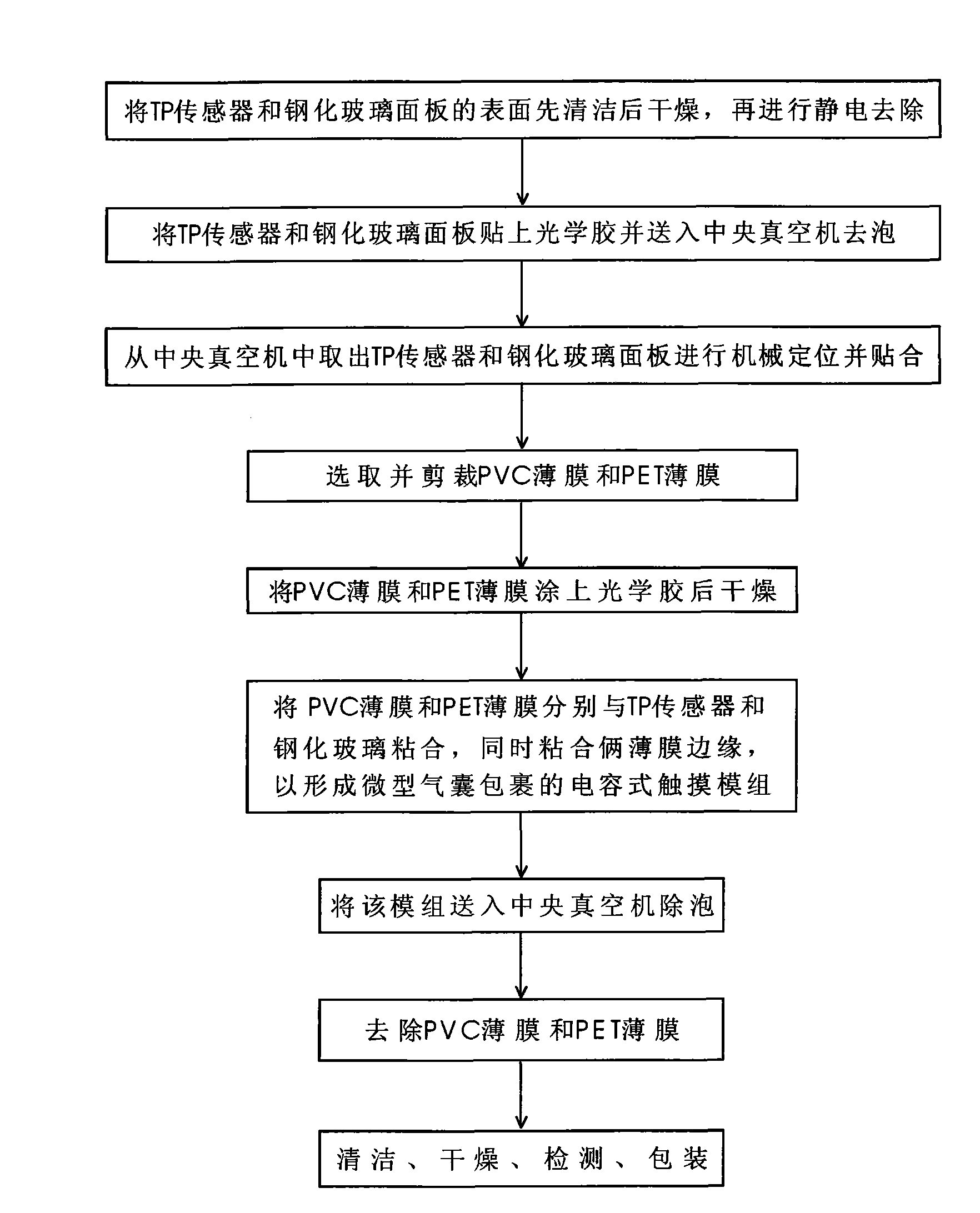

[0017] Such as image 3 As shown, the capacitive touch screen bonding process of the present invention includes the following steps: 1. Clean and dry the surfaces of the TP sensor 1 and the tempered glass panel 3 first, and then remove static electricity; 2. Put the TP sensor 1 and the tempered glass panel 3 Paste optical glue and send it to the central vacuum machine to remove bubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com