Preparation method of long-chain alkyl polyether co-modified silicone oil

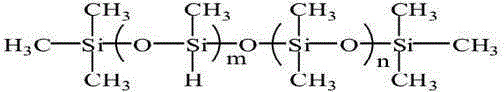

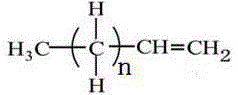

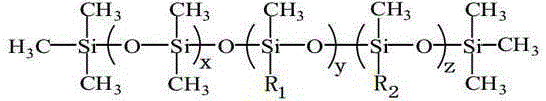

The technology of long-chain alkyl polyether and long-chain alkyl group is applied in the field of preparation of long-chain alkyl polyether co-modified silicone oil, which can solve the problems of low quality, inability to meet production requirements, backward synthesis process, etc. The effect of good defoaming effect, improving stability and feeling of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: First add 10 parts of hydrogen-containing silicone oil and 40 parts of allyl polyoxyethylene polyoxypropylene ether into a dry 250 mL four-necked bottle at one time, stir and heat. When the temperature in the flask reaches 50°C, add 2ppm Pt catalyst, start timing when the temperature rises to 80°C, at this time there will be smoke and reflux in the flask, and there will be more bubbles on the liquid surface. The temperature of the system gradually increased due to the exothermic reaction, and the addition reaction was controlled at 120°C. After 60 minutes, 32 parts of long-chain alkyl unsaturated olefins were added dropwise, and the temperature was maintained at 120°C. Under MPa, the temperature was gradually raised to 180°C, and the unreacted raw materials were removed to obtain a colorless and transparent product.

Embodiment 2

[0032] Example 2: Add 10 parts of hydrogen-containing silicone oil to a dry 250mL four-necked bottle at one time, stir and heat. When the temperature in the flask reaches 50°C, add 2ppm Pt catalyst, and when the temperature reaches 80°C, add 40 parts of allyl polyoxyethylene polyoxypropylene ether, and within the first 60 minutes, allyl polyoxyethylene polyoxypropylene ether and hydrogen-containing In addition reaction of silicone oil, 32 parts of long-chain alkyl unsaturated olefins were added dropwise at the last 60 minutes, and the temperature was maintained at 120°C for 12 hours. Raw material, a colorless and transparent product was obtained.

Embodiment 3

[0033] Example 3: Add 10 parts of hydrogen-containing silicone oil to a dry 250mL four-necked bottle at one time, stir and heat. When the temperature in the flask reaches 50°C, add 2ppm of Pt catalyst, and when the temperature reaches 80°C, start to add dropwise a mixture of 40 parts of allyl polyoxyethylene polyoxypropylene ether and 10 parts of long-chain alkyl unsaturated olefins, and after 60 minutes Start to add 22 parts of long-chain alkyl unsaturated olefins dropwise, maintain the temperature at 120°C for 12 hours, and then gradually raise the temperature to 180°C at -0.098MPa to remove unreacted raw materials to obtain a colorless and transparent product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com