Spiral defoamer

A defoamer and screw technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of complicated manufacture of closed turbine defoamer, poor adaptability of rake defoamer and scraper defoamer, etc. Low manufacturing cost and good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

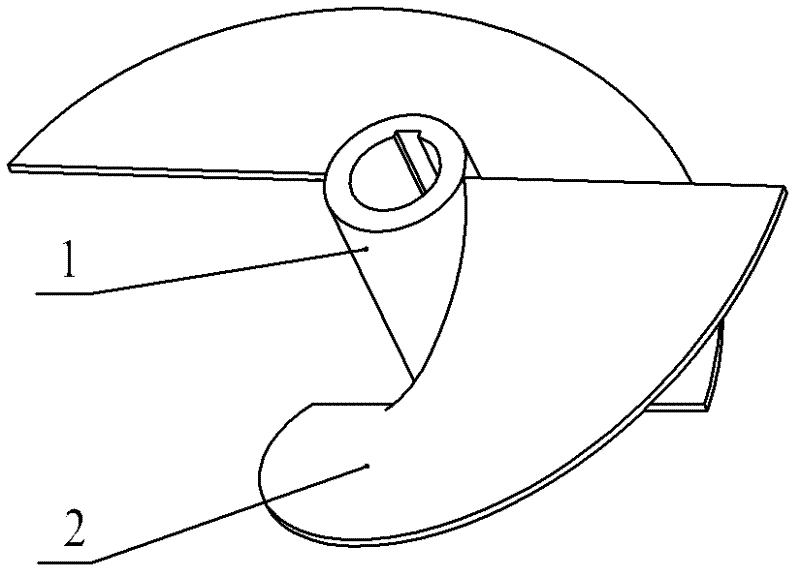

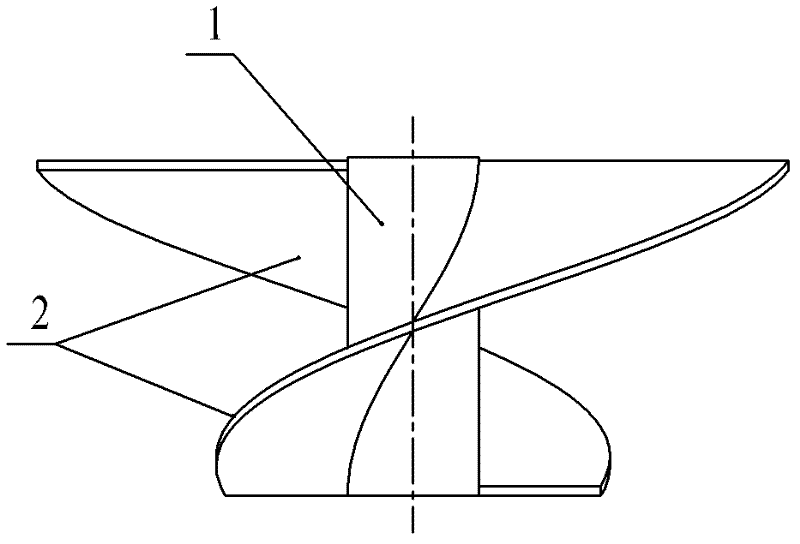

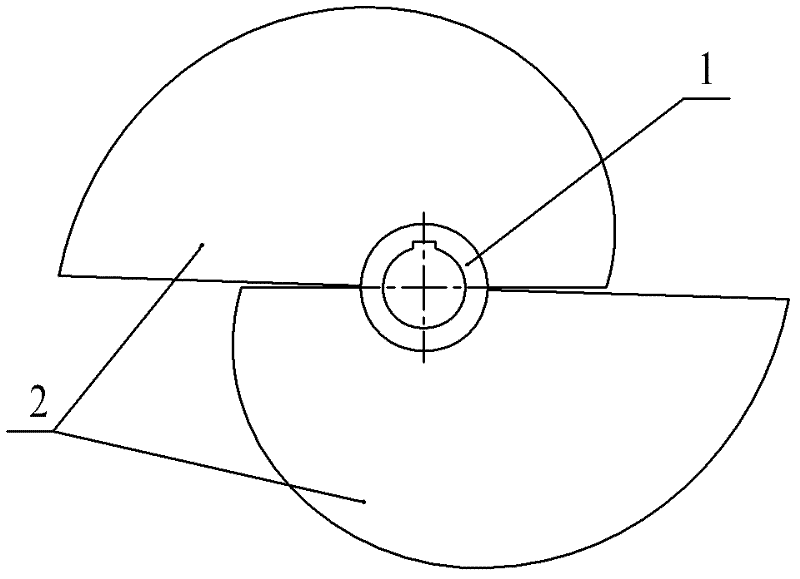

[0011] As shown in the figure: the spiral defoamer mainly includes two parts: the hub 1 and the paddle 2, the hub 1 is long cylindrical, the paddle 2 is helical, the paddle 2 has two pieces, two paddles The blades 2 are symmetrically arranged, and the inner edge of the blade 2 is welded to the outer wall of the hub 1 along the length direction of the hub 1 by spiral welding.

[0012] When working, the spiral defoamer rotates driven by the stirring shaft, and the central material liquid is pushed to the outer edge of the paddle 2 under the action of the forced thrust and centrifugal force of the helical surface of the paddle 2, and is sprayed to the liquid surface through the edge of the paddle 2 The foam layer plays the role of breaking the foam.

[0013] like Figure 1~Figure 3 As shown, the paddle 2 is drawn from a flat plate, the plane of the paddle 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com