Production method of environmental-friendly type low-cost middle and high density fiber board

A high-density fiberboard, production method technology, applied in the direction of adhesive types, non-polymer adhesive additives, household components, etc. The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

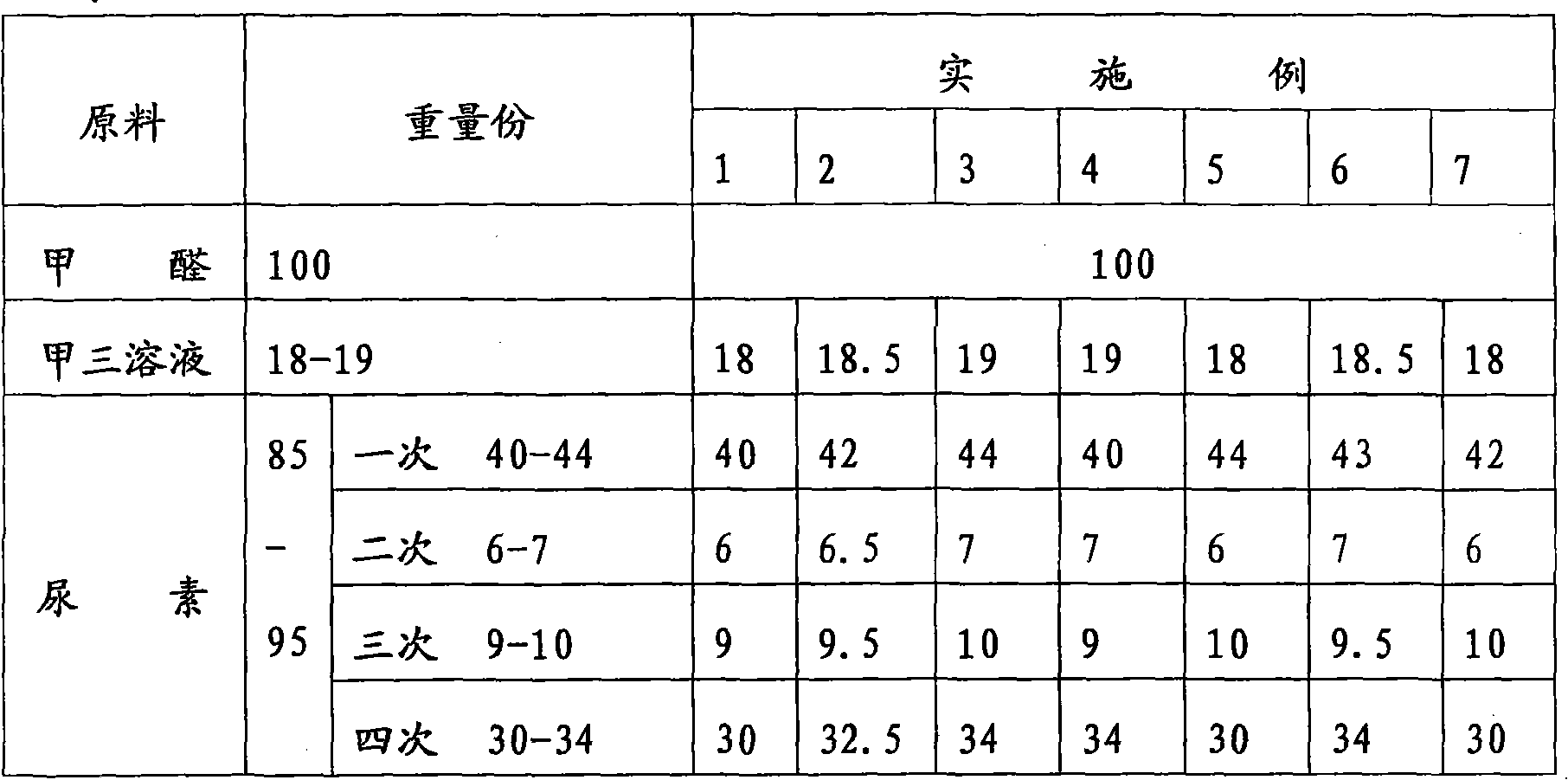

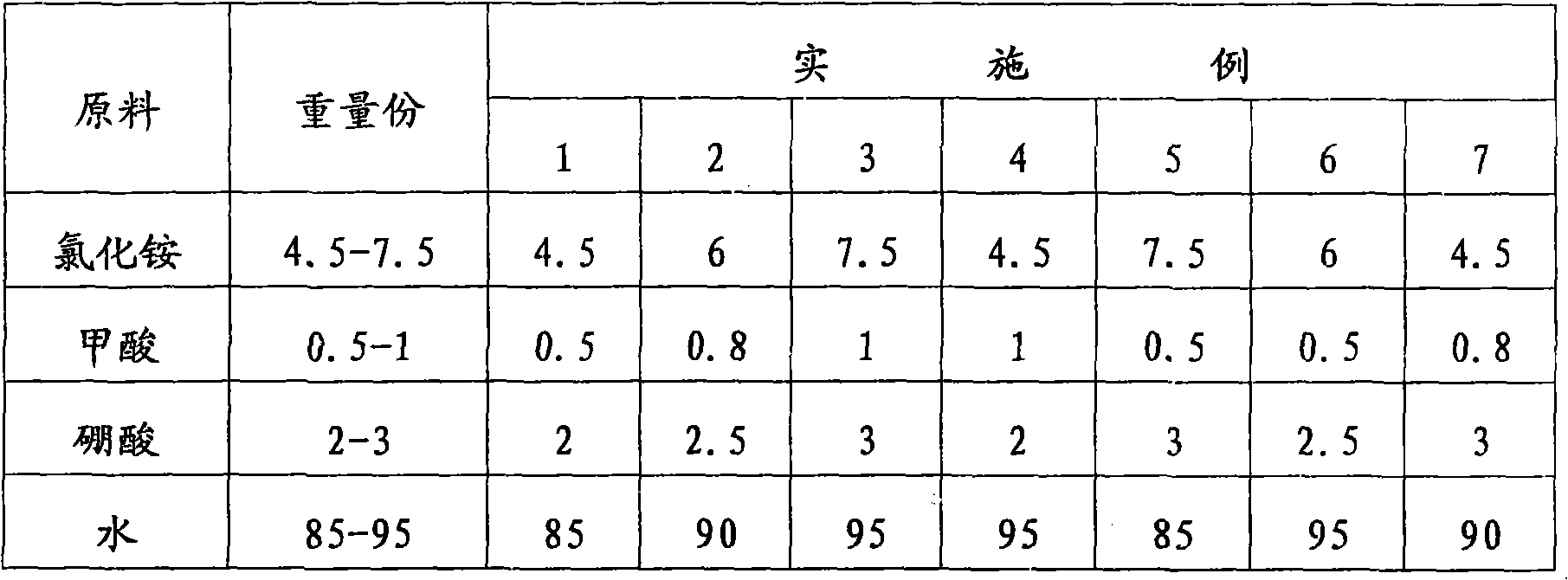

[0054] Embodiment 1 (the raw material of corresponding embodiment 1 and the proportioning value by weight in the comparison table):

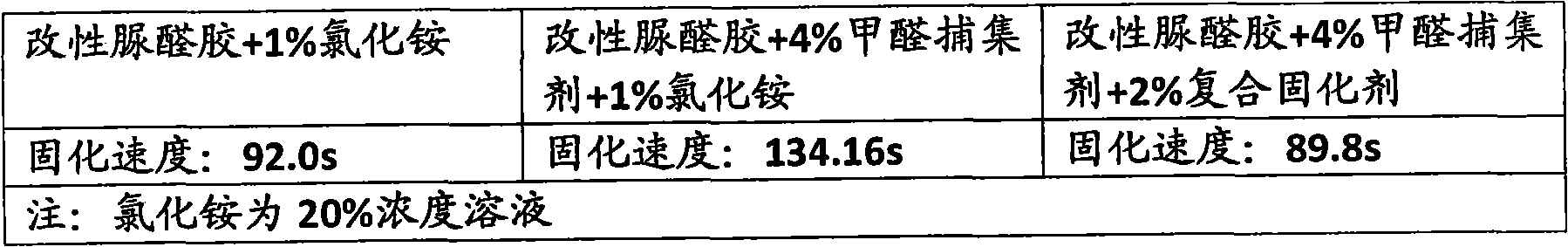

[0055] Add 100 parts by weight of formaldehyde solution with a concentration of 37.2% (hereinafter referred to as parts) into the reaction kettle, adjust the pH to ≥ 8 with 30% NaOH, heat, add 40 parts of formaldehyde for the first time, raise the temperature to 60°C, stop heating, and add formaldehyde Solution (i.e. formaldehyde melamine solution) 18 parts, heat up to 80-85°C, heat preservation reaction for 0.5h, cool to 80-75°C, adjust pH=4.5 with 25% formic acid in 2-3 times, measured 20 When the viscosity is 15S in 4 cups at ℃, add NaOH to adjust the pH=5.2, add 6 parts of urea for the second time, and raise the temperature to 80-85 °C for reaction. When the viscosity is 16S, add 9 parts of urea for the third time, and then raise the temperature to 80 React at -85°C, when the viscosity is measured at 19S, add NaOH to adjust the pH ≥ 7.5, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com