Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

A technology of urea-formaldehyde resin and aqueous solution, which is applied in the direction of aldehyde/ketone condensation polymer adhesive, adhesive type, adhesive, etc., can solve the problems of environmental pollution, emission, and reduce the production cost of particleboard, so as to reduce the production cost and reduce the production cost. Fuel and power consumption, the effect of increasing rubber consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 urea-formaldehyde resin 1

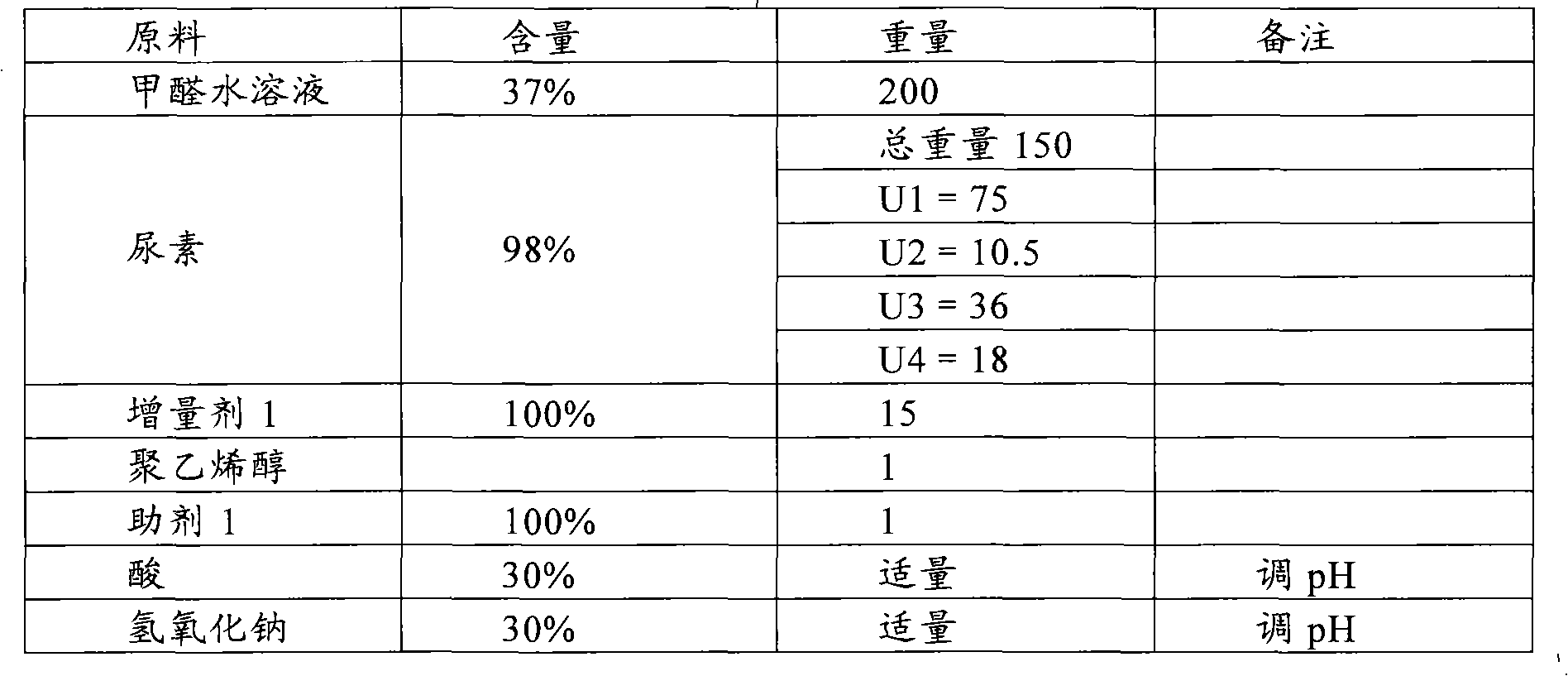

[0036] Raw material formula:

[0037]

[0038] Wherein, the components of the bulking agent 1 are: 10 parts by weight of sodium carboxymethyl cellulose, and 90 parts by weight of sodium chloride.

[0039] Extender 1 main technical indicators: density: 1.9-2.1; pH: 7-8; appearance: white powder; moisture: ≤4%.

[0040] The components of additive 1 are: 40 parts by weight of ammonium sulfate, 30 parts by weight of 2-hydroxypropionic acid, and 30 parts by weight of urea.

[0041] Main technical indicators of additive 1: density: 1.1-1.3, pH: 5-7, appearance: white powder, moisture: ≤4%.

[0042] Specific steps are as follows:

[0043] 1) Add 37% formaldehyde aqueous solution to the reaction kettle at one time, add polyvinyl alcohol and extender 1, turn on the steam and heat to 30-40°C, and turn off the steam;

[0044] 2) Use sodium hydroxide aqueous solution to adjust the pH to 8.8, add U1, then open the st...

Embodiment 2

[0057] The preparation of embodiment 2 urea-formaldehyde resin 2

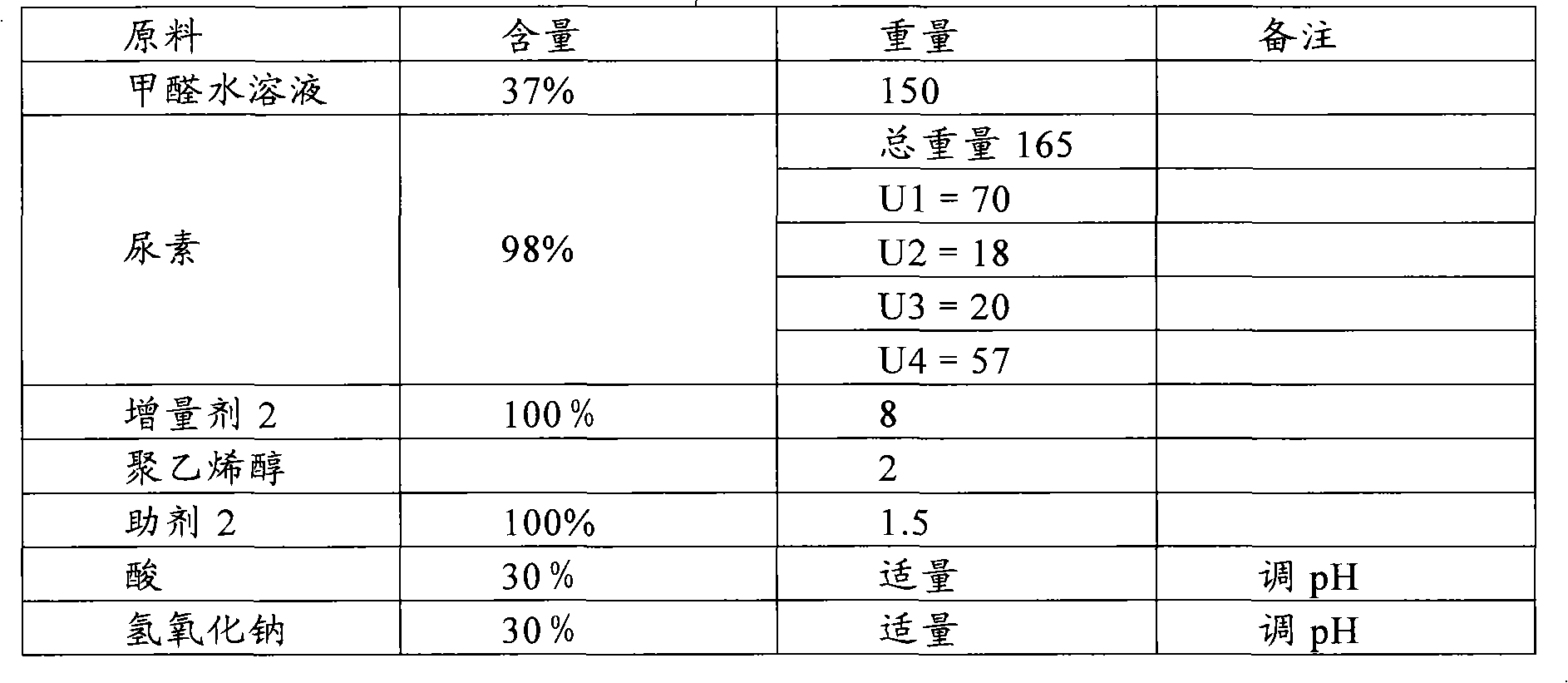

[0058]

[0059] Wherein, the components of the bulking agent 2 are: 50 parts by weight of defatted protein, and 50 parts by weight of silicon dioxide.

[0060] Extender 2 main technical indicators: density: 1.3-1.5; pH: 7-8; appearance: white powder; moisture: ≤4%.

[0061] The components of auxiliary agent 2 are: 30 parts by weight of ammonium phosphate, 30 parts by weight of stearic acid, and 40 parts by weight of sodium dihydrogen phosphate.

[0062] Main technical indicators of additive 2: density: 1.4-1.6, pH: 5-7, appearance: white powder, moisture: ≤4%.

[0063] Concrete steps are with embodiment 1, the quality index of gained urea-formaldehyde resin 2:

[0064] Solid content: 56%;

[0065] pH: 8.0;

[0066] Viscosity (20°C): 180cp;

[0067] Curing time: 60s;

[0068] Free formaldehyde content: <0.1%;

[0069] Storage period: >30 days.

Embodiment 3

[0070] The preparation of embodiment 3 urea-formaldehyde resin 3

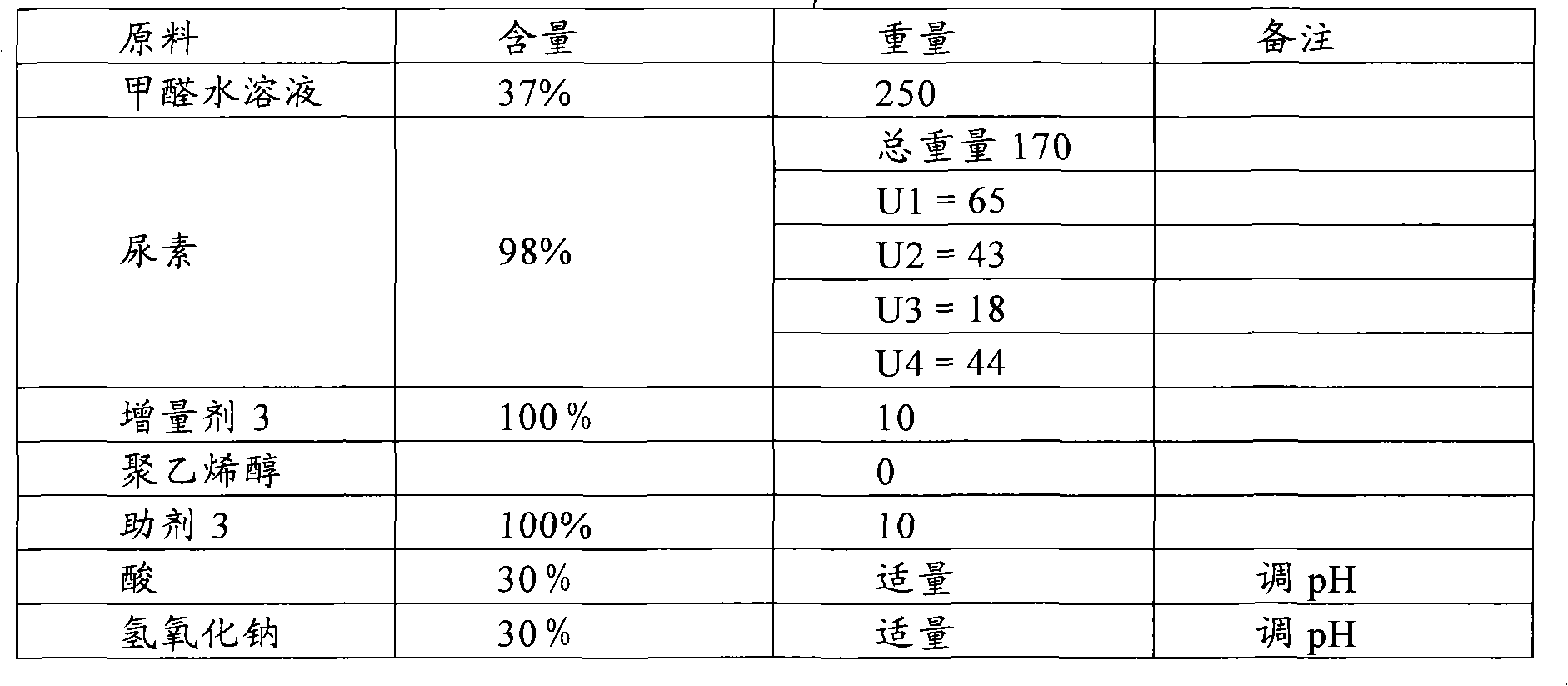

[0071]

[0072] Wherein, the components of the extender 3 are: 5 parts by weight of soybean protein isolate, and 95 parts by weight of attapulgite.

[0073] Extender 3 main technical indicators: density: 1.3-1.5; pH: 7-8; appearance: white powder; moisture: ≤4%.

[0074] The components of additive 3 are: 50 parts by weight of ammonium nitrate, 30 parts by weight of o-hydroxybenzoic acid, and 20 parts by weight of urea.

[0075] Main technical indicators of additive 3: density: 1.2-1.4, pH: 3-5, appearance: white powder, moisture: ≤4%.

[0076] Concrete steps are with embodiment 1, the quality index of gained urea-formaldehyde resin 3:

[0077] Solid content: 55%;

[0078] pH: 8.0;

[0079] Viscosity (20°C): 140cp;

[0080] Curing time: 65s;

[0081] Free formaldehyde content: <0.1%;

[0082] Storage period: >30 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com