Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

A technology of urea-formaldehyde resin and adhesive, applied in the direction of aldehyde/ketone condensation polymer adhesive, process for producing decorative surface effect, adhesive, etc., can solve problems such as shrinkage, deformation and cracking, reduce shrinkage, improve Appreciation of art, improvement of cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1, the preparation of modified acrylic acid, sodium acrylate, N, N-dimethylaminopropyl methacrylamide copolymer:

[0026] 1) Take 10g of acrylic acid and neutralize it with 3.33g of sodium hydroxide in an ice bath, and the neutralization degree is about 60%, to obtain a solution ①; 2) Take 10g of N, N-dimethylaminopropyl methacrylamide and add it to the above solution ① , then add 443g of distilled water to make an aqueous solution with a mass fraction of about 5% ②; 3) add 0.1167g of ammonium persulfate to the above aqueous solution ② as an initiator, and react at a constant temperature of 65°C for 4 hours under stirring to obtain acrylic acid and sodium acrylate , N, N-dimethylaminopropyl methacrylamide copolymer aqueous solution ③; 4) get 100g 30% polyethylene glycol 6000 aqueous solution and 100g 5% polyvinyl alcohol 1792 aqueous solution, and blend uniformly to obtain aqueous solution ④; 5 ) Take 300g of aqueous solution ③ and 100g of aqueous solution ④ and bl...

Embodiment 2

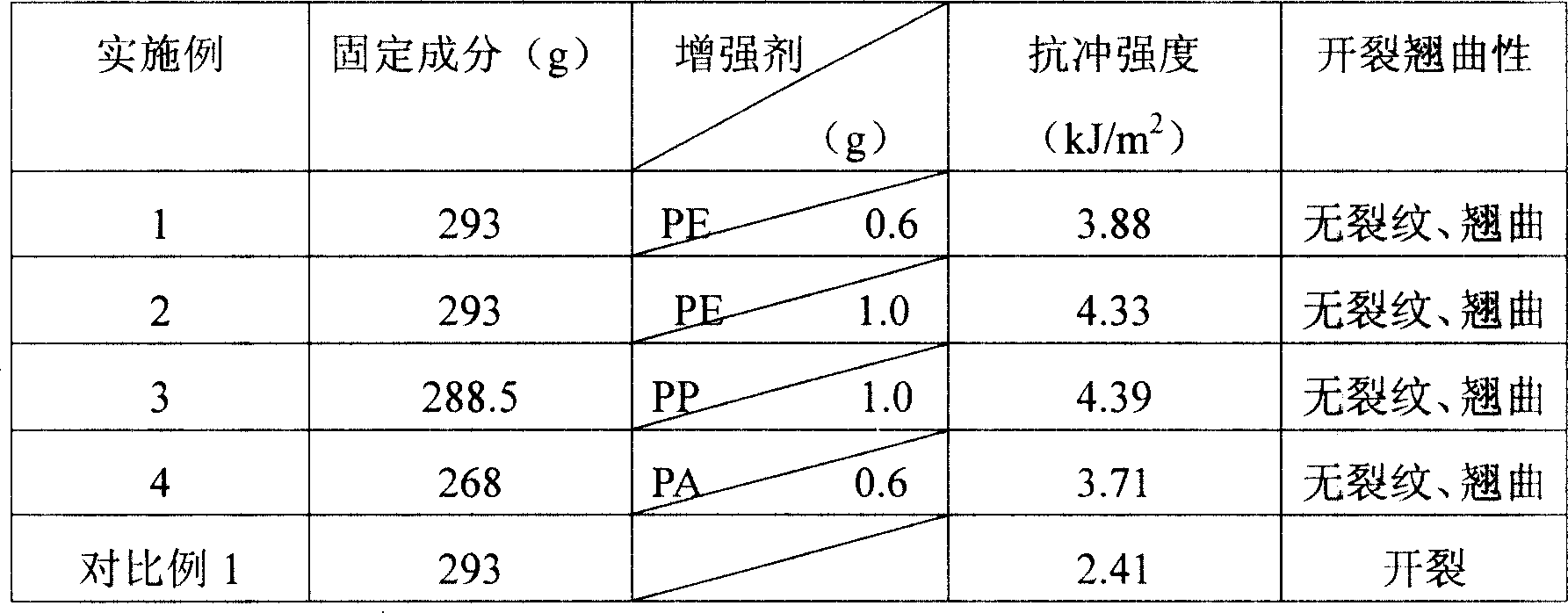

[0033] Example 2: Change the amount of PE fiber to 1.0 g, and the rest are the same as in Example 1. The measurement results of impact strength, cracking and warpage and other properties are shown in Table 2.

Embodiment 3

[0035]Step 1, the preparation of modified acrylic acid, sodium acrylate, N,N-dimethylaminopropyl methacrylamide copolymer: 1) get 10g acrylic acid and neutralize in ice bath with 4.44g sodium hydroxide, neutralization degree About 80% to obtain solution ①; 2) Add 10g N, N-dimethylaminopropyl methacrylamide to the above solution ①, and then add 220g distilled water to make an aqueous solution with a mass fraction of about 10% ②; 3) Add 0.1222g of ammonium persulfate to the above aqueous solution ② as an initiator, and react at a constant temperature of 85°C for 3 hours under stirring to obtain an aqueous solution of acrylic acid, sodium acrylate, N,N-dimethylaminopropyl methacrylamide copolymer ③; 4 ) take 50g of 20% polyethylene glycol 6000 aqueous solution and 50g of 10% polyvinyl alcohol 1792 aqueous solution, and blend them uniformly to obtain an aqueous solution ④; Modified acrylic acid, sodium acrylate, N, N-dimethylaminopropyl methacrylamide copolymer (anti-shrinkage age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com