Urea-formaldehyde resin coated epoxy acrylic resin microcapsule for resin-base self-repair coating and preparation method thereof

A technology of coating epoxy acrylic acid and epoxy acrylic acid, which is applied in the field of urea-formaldehyde resin coating epoxy acrylic resin microcapsules and preparation, can solve the problems of loss of catalytic activity and affecting repair efficiency, etc., achieve low cost, expand application range, and The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

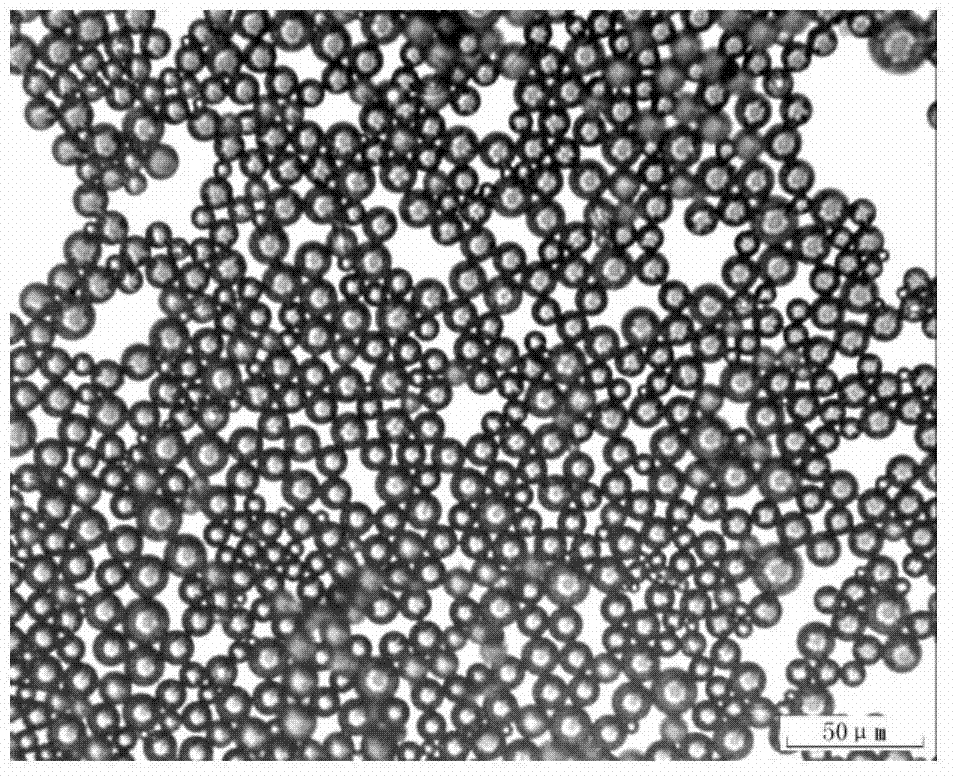

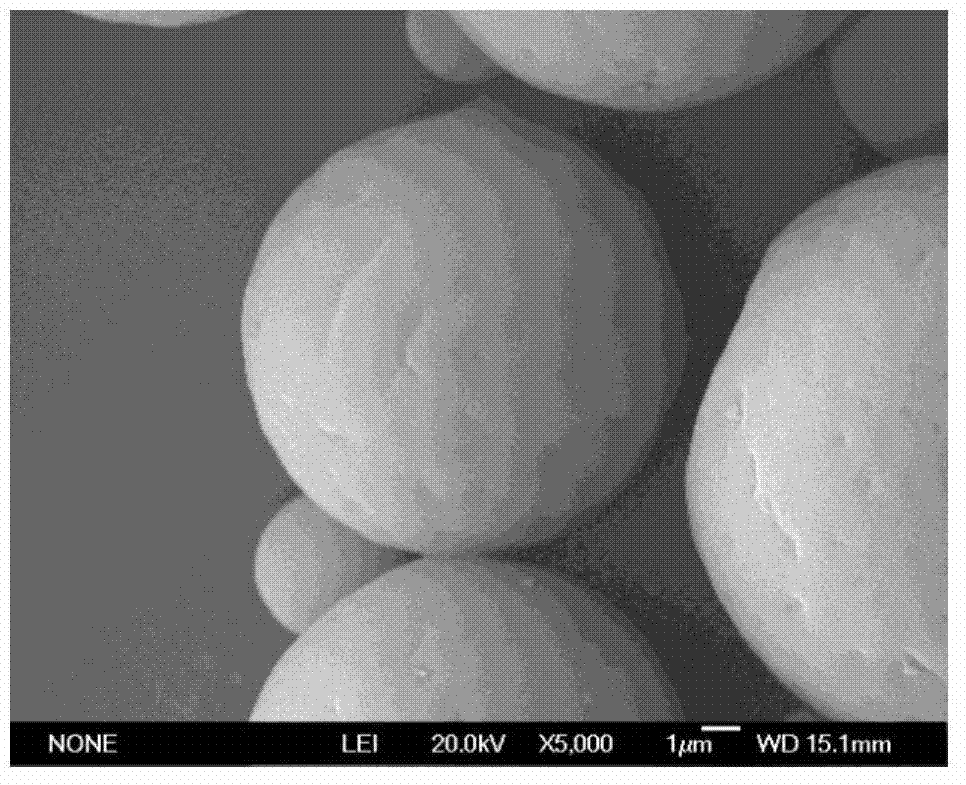

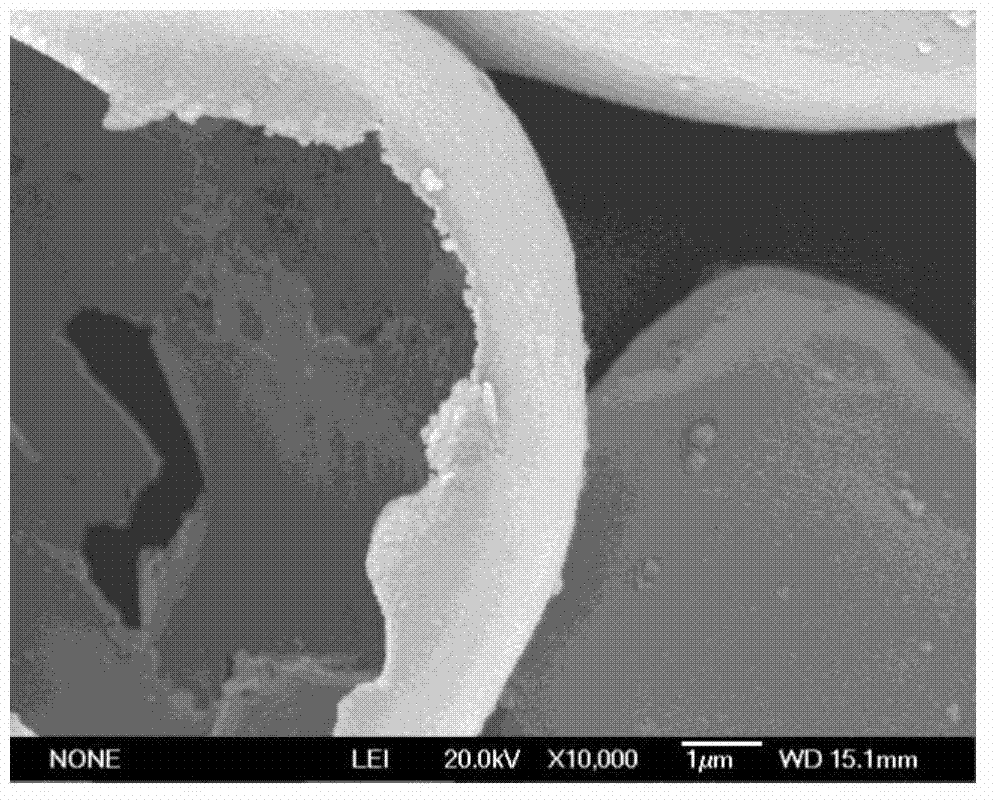

[0027] In a 100ml three-necked bottle, add 60g of styrene-maleic anhydride emulsifier with a mass fraction of 5%, add 2 drops of n-octanol as a defoamer, mix 5g of epoxy acrylic resin and 5g of tripropylene glycol diacrylate, and add In the above emulsifier aqueous solution, emulsify at 1000rpm for 10min, adjust the pH to 2.5 with 10% citric acid, raise the temperature of the reaction system to 70°C at a heating rate of 5°C / min, add 1.5g urea, 0.2g resorcinol, 3g Formaldehyde solution with a mass fraction of 37% was used to maintain the reaction for 2 hours, and the reaction ended. The reacted system was washed 5 times with deionized water at 60° C., centrifuged, suction filtered and freeze-dried to obtain a white microcapsule product.

Embodiment 2

[0029] In a 100ml three-necked bottle, add 60g of styrene-maleic anhydride emulsifier with a mass fraction of 5%, add 2 drops of n-octanol as a defoamer, and mix 7.5g of epoxy acrylic resin and 2.5g of tripropylene glycol diacrylate , add the above emulsifier aqueous solution, emulsify at 1000rpm for 10min, adjust the pH to 2.5 with 10% citric acid, raise the temperature of the reaction system to 70°C at a heating rate of 5°C / min, add 1.5g urea, 0.2g resorcinol , 3g of formaldehyde solution with a mass fraction of 37%, maintain the reaction for 2h, and the reaction ends. The reacted system was washed 5 times with deionized water at 60° C., centrifuged, suction filtered and freeze-dried to obtain a white microcapsule product.

Embodiment 3

[0031] In a 100ml three-necked bottle, add 60g of styrene-maleic anhydride emulsifier with a mass fraction of 4%, add 2 drops of n-octanol as a defoamer, mix 5g of epoxy acrylic resin and 5g of tripropylene glycol diacrylate, and add In the above emulsifier aqueous solution, emulsify at 1000rpm for 10min, adjust the pH to 2.5 with 10% citric acid, raise the temperature of the reaction system to 70°C at a heating rate of 5°C / min, add 1.5g urea, 0.2g resorcinol, 3g Formaldehyde solution with a mass fraction of 37% was used to maintain the reaction for 2 hours, and the reaction ended. The reacted system was washed 5 times with deionized water at 60° C., centrifuged, suction filtered and freeze-dried to obtain a white microcapsule product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com