High friction composite brake shoe for railway freight car and manufacture method thereof

A technology for synthesizing brake shoes and railway wagons, which is applied in the direction of railway braking systems, railway car body parts, brake parts, etc., can solve the problems of insufficient friction performance, failure to meet braking requirements, and endanger driving safety, etc., and achieve good Self-cleaning property, reduction of wheel damage, effect of inhibiting metal inlays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

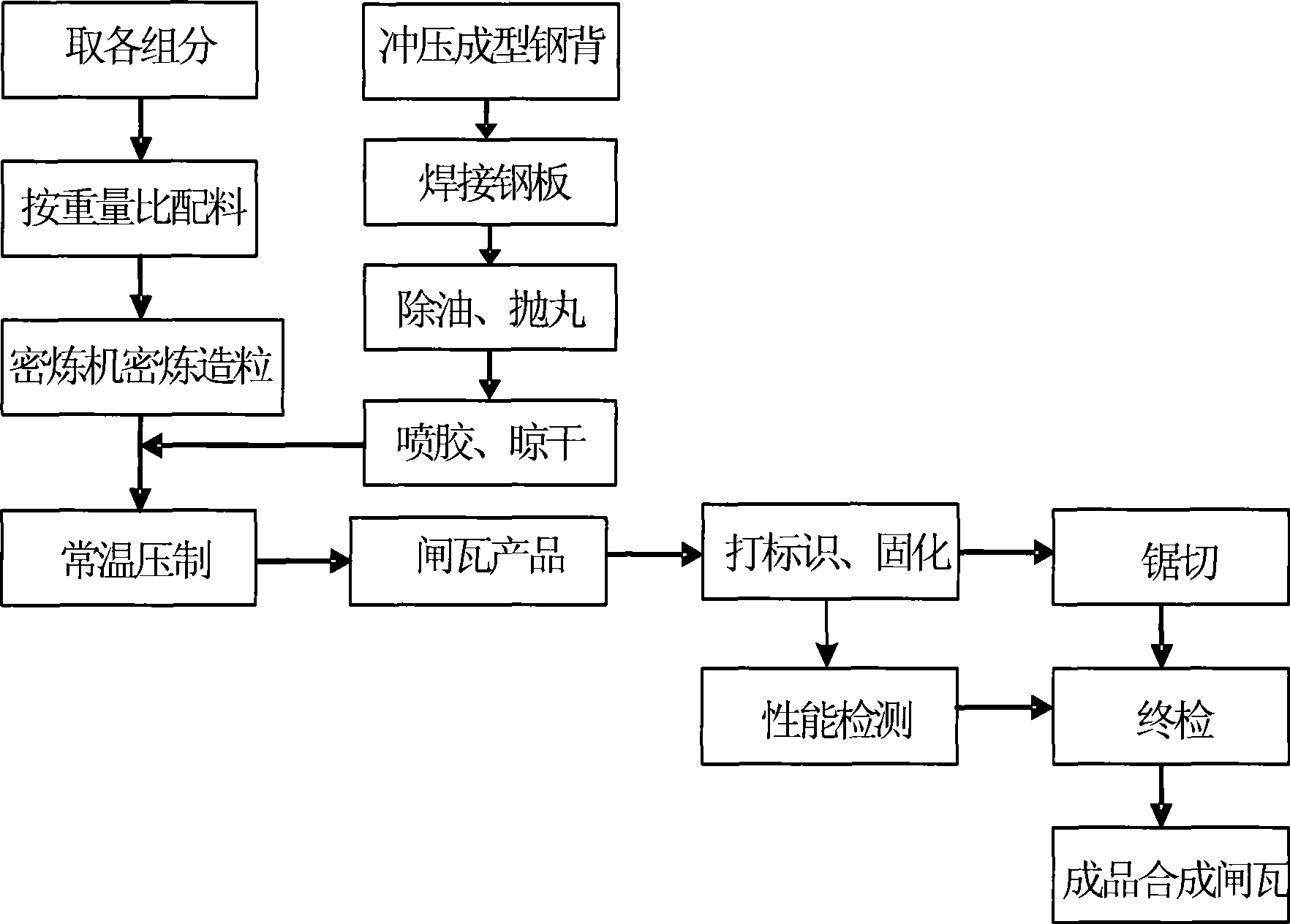

Image

Examples

Embodiment 1

[0031] This embodiment provides a high-friction composite brake shoe for railway freight cars. The composite brake shoe is composed of a steel back and a brake shoe body. The brake shoe body is fixed on the steel back to form an integrated synthetic brake shoe. The specific structure is similar to that of existing railways. The brake shoe components on the truck are basically the same. The main difference from the existing brake shoe components is the synthetic material used to make the brake shoe body, which is a polymer composite material synthesized from the following components in a weight ratio, including:

[0032] Nitrile rubber 8~13, styrene butadiene rubber 2~10, cresol modified resol phenolic resin 5~10, steel fiber 15~30, magnesium oxide 10~15, calcined petroleum coke 5~10, silicon carbide 2~5 , Mineral fiber 10-25, calcium hydride 5-10, barium sulfate 10-20, graphite 5-10, molybdenum disulfide 1-5, carbon black 1-5, sulfur 1-3, accelerator 1-3.

[0033] Among them, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com