Railway wagon bottom floor damage fault detection method

A railway freight car and fault detection technology, which is applied in the direction of railway car body parts, railway vehicle testing, chassis, etc., can solve the problems of low efficiency and poor reliability, and achieve the effects of unified operation standards, improved division speed and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

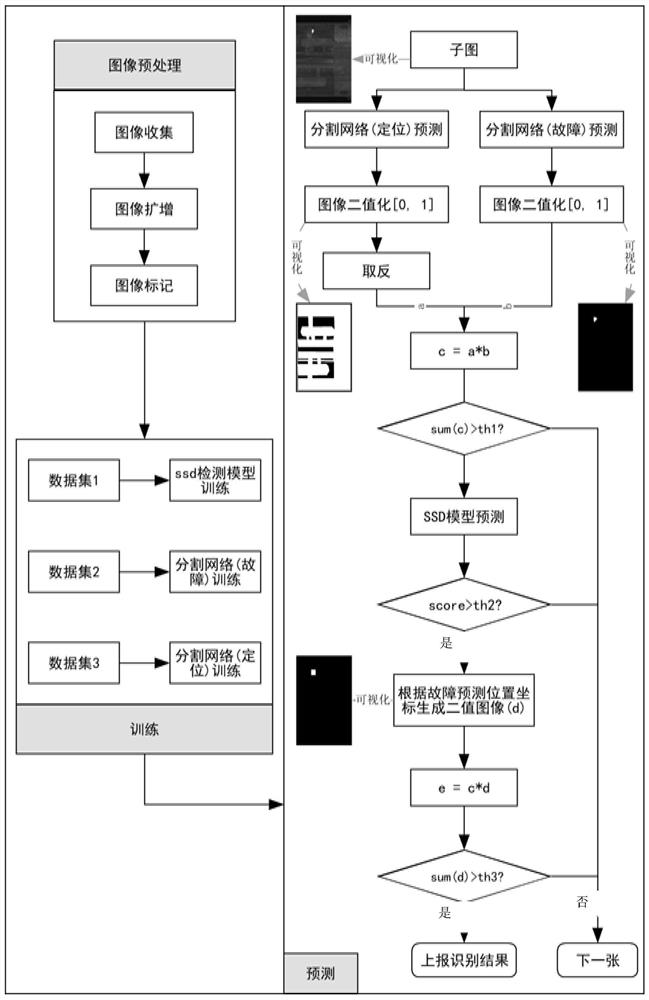

[0066] Specific implementation mode 1. Combination Figure 1 to Figure 3 As shown, the present invention provides a method for detecting damage to the floor of a railway wagon bottom, including:

[0067] Collect linear array images of the bottom of the railway freight car under different conditions;

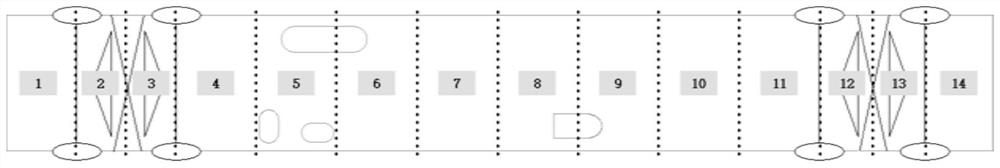

[0068] Splitting each car section in the full-vehicle linear array image evenly along the length direction of the railway freight car into n grayscale images; the n is the number of preset splits;

[0069] Carrying out image preprocessing on the grayscale image, and performing data amplification to obtain a sample data set;

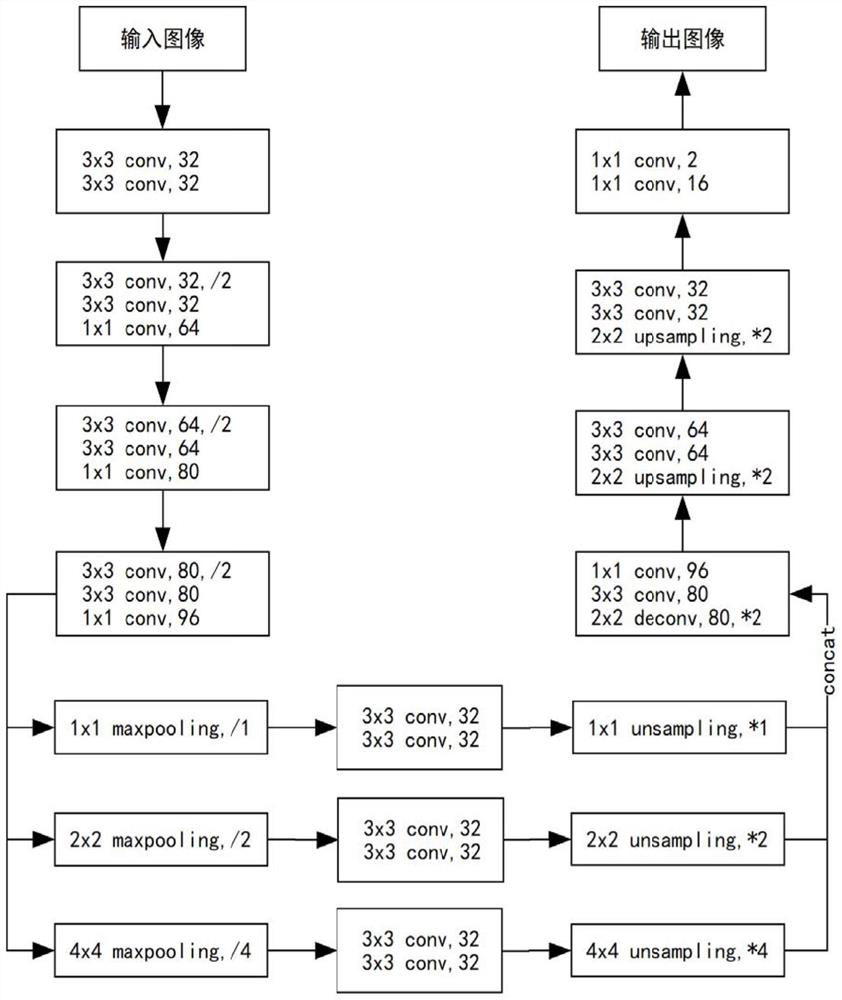

[0070] Construct a semantic segmentation neural network model based on the encoder and decoder, and make each convolution layer have a convolution function, a batch normalization function and a Relu activation function;

[0071] The sample data set is divided into a training data set and a test data set; the grayscale image in the training data set is pred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com