HGM-C type high friction composite brake shoe and preparation method thereof

A HGM-C, 1.HGM-C technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of increased maintenance and replacement costs, short service life, wheel scratches, etc., to achieve long service life and reduce wheels. damage and improve fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

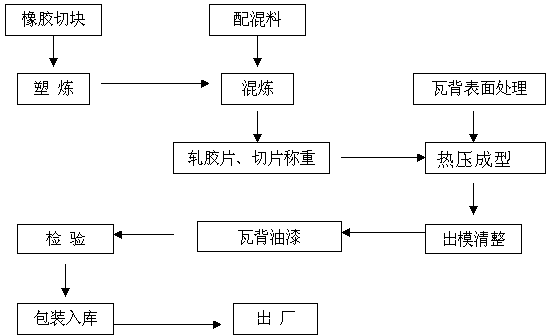

Image

Examples

Embodiment 1

[0020] The preparation method of the HGM-C type high-friction synthetic brake shoe, the steps are as follows in parts by weight:

[0021] (1) Ingredients: Extract the raw materials of each component of the friction material according to the corresponding weight percentage;

[0022] The weight percentages of each component are: 18 parts of styrene-butadiene rubber, 2 parts of butadiene rubber, 5 parts of cresol modified resole phenolic resin, 15 parts of steel fiber, 5 parts of magnesium oxide, 5 parts of petroleum coke, 2 parts of silicon carbide 10 parts of mineral fiber, 5 parts of calcium hydroxide, 5 parts of barium sulfate, 5 parts of graphite, 1 part of molybdenum disulfide, 6 parts of iron powder, 1 part of N539 carbon black, 1 part of sulfur, 1 part of antimony sulfide and accelerator TMTD 0.1 part;

[0023] (2) Mastication: Take styrene-butadiene rubber and butadiene rubber, cut them into pieces according to the thickness and width of the rubber package in the length...

Embodiment 2

[0030] The preparation method of the HGM-C type high-friction synthetic brake shoe, the steps are as follows in parts by weight:

[0031] (1) Ingredients: Extract the raw materials of each component of the friction material according to the corresponding weight percentage;

[0032] The weight percentages of each component are: 22 parts of styrene-butadiene rubber, 10 parts of butadiene rubber, 10 parts of cresol modified resole phenolic resin, 30 parts of steel fiber, 10 parts of magnesium oxide, 10 parts of petroleum coke, 5 parts of silicon carbide 25 parts of mineral fiber, 10 parts of calcium hydroxide, 10 parts of barium sulfate, 10 parts of graphite, 5 parts of molybdenum disulfide, 10 parts of iron powder, 5 parts of N539 carbon black, 3 parts of sulfur, 3 parts of antimony sulfide and accelerator TMTD 0.6 copies;

[0033] (2) Mastication: take 22 parts of styrene-butadiene rubber and 10 parts of butadiene rubber, cut into pieces of 200 mm in length direction according...

Embodiment 3

[0040] The preparation method of the HGM-C type high-friction synthetic brake shoe, the steps are as follows in parts by weight:

[0041] (1) Ingredients: Extract the raw materials of each component of the friction material according to the corresponding weight percentage;

[0042] The weight percentages of each component are: 20 parts of styrene-butadiene rubber, 8 parts of butadiene rubber, 8 parts of cresol modified resole phenolic resin, 25 parts of steel fiber, 8 parts of magnesium oxide, 7 parts of petroleum coke, 3 parts of silicon carbide 18 parts of mineral fiber, 8 parts of calcium hydroxide, 6 parts of barium sulfate, 9 parts of graphite, 4 parts of molybdenum disulfide, 7 parts of iron powder, 4 parts of N539 carbon black, 3 parts of sulfur, 3 parts of antimony sulfide and accelerator TMTD 0.3 copies;

[0043] (2) Mastication: Take styrene-butadiene rubber and butadiene rubber, cut them into pieces according to the thickness and width of the rubber package in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com