Wagon brake system

A technology for braking systems and railway wagons, applied in railway braking systems, railway car body parts, pneumatic brakes, etc., can solve the problems of waste of pressure air, low braking efficiency, no anti-skid device, etc., and achieve improved braking power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

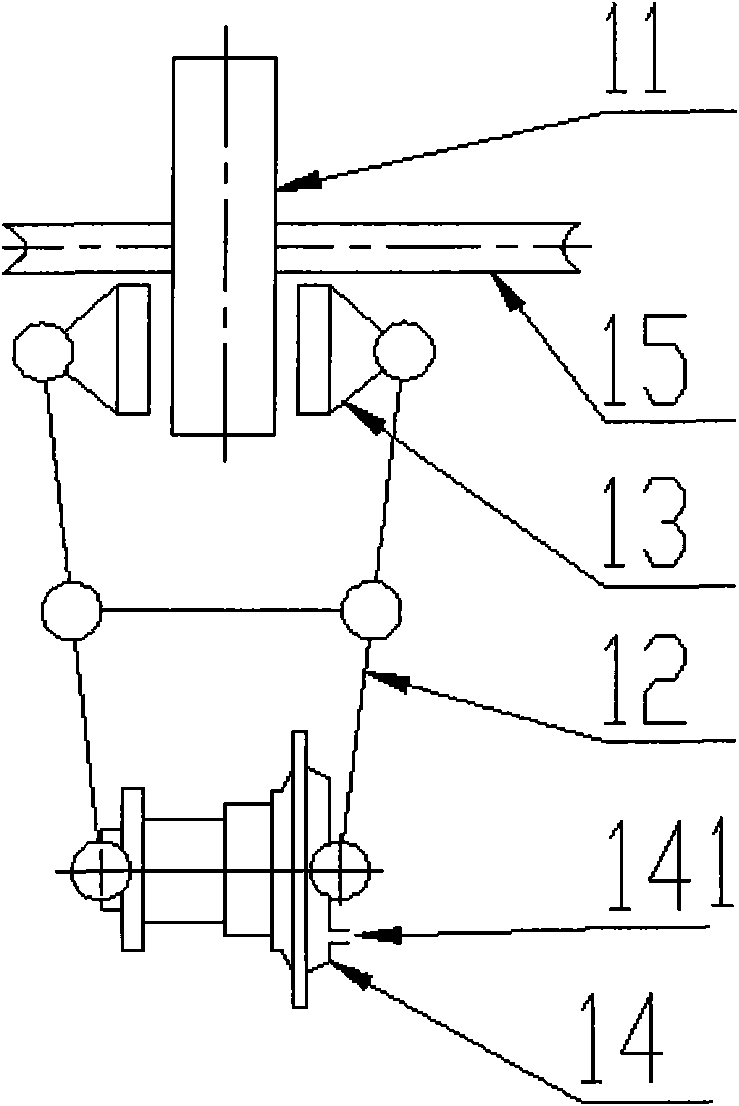

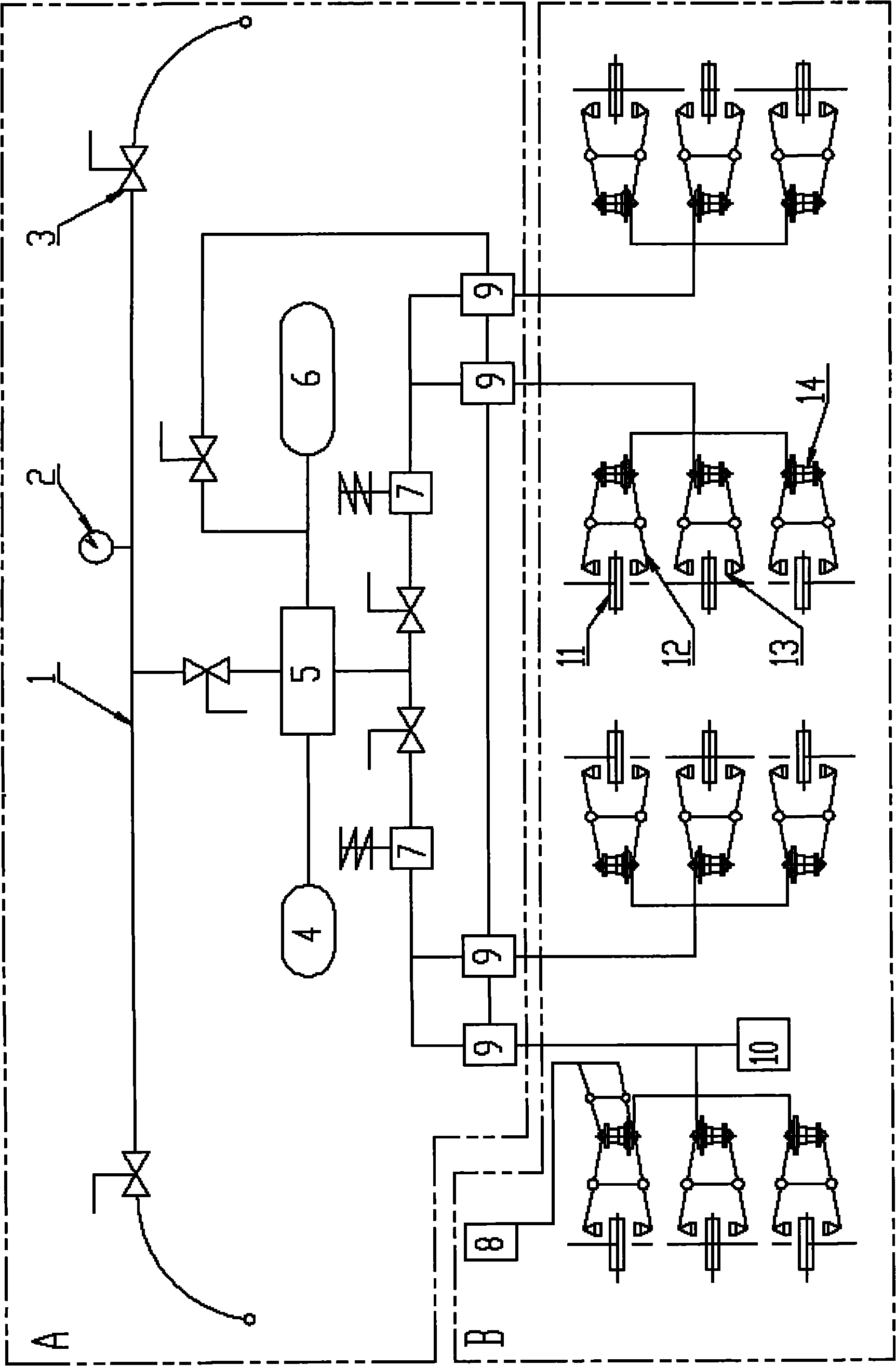

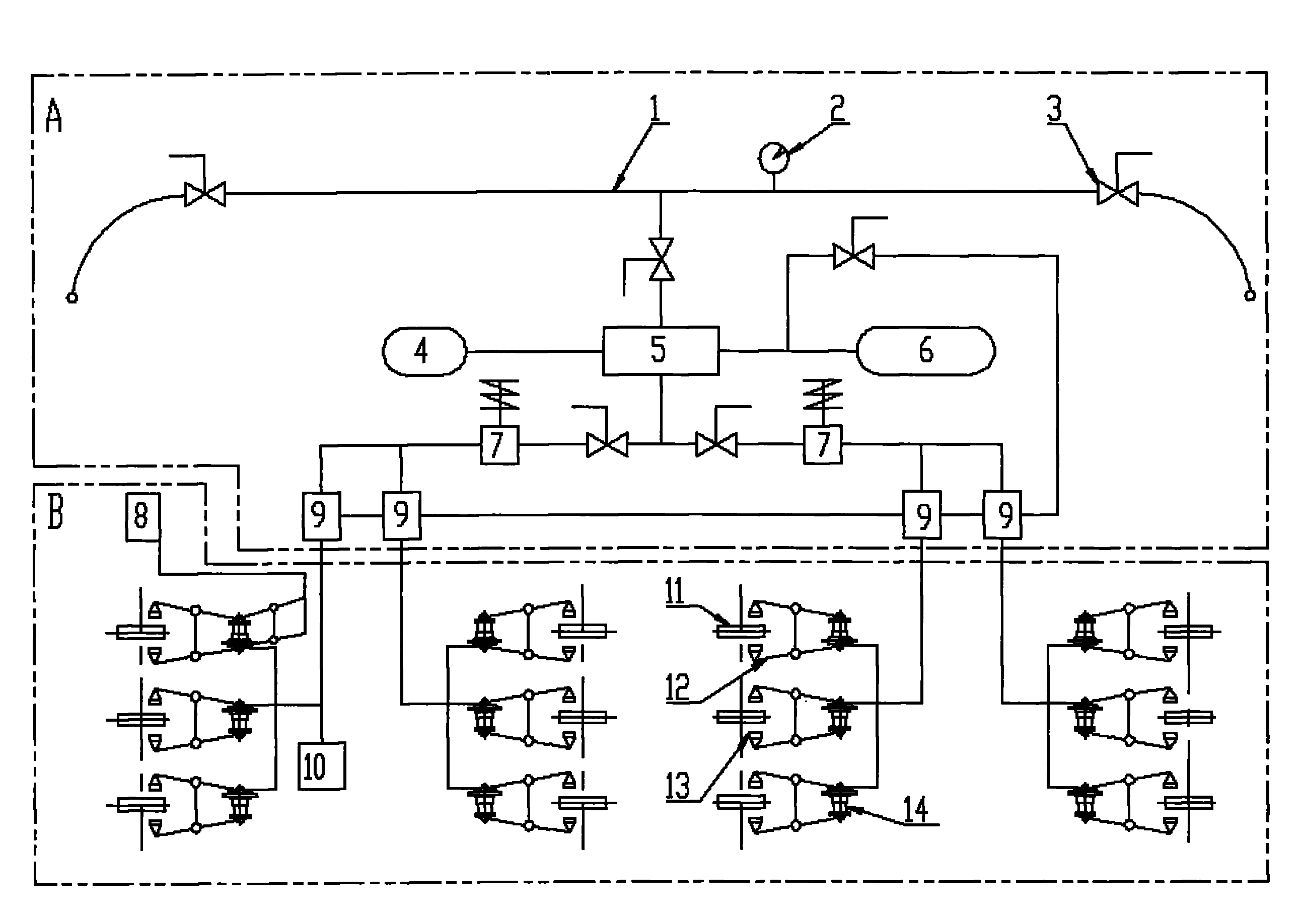

[0030] The specific embodiments and system structure of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The railway freight car braking system of the present invention includes a braking control system and a basic braking system. The brake control system includes air cylinders (including working air cylinders and auxiliary air cylinders), indirect-acting brake control valves, pressure-regulating empty-heavy truck automatic adjustment devices and anti-skid devices, and piping systems connecting these components; basic braking system At least one disc brake is included. like figure 1 As shown, the disc brake device includes a brake disc 11 that rotates with the axle, a lever system 12, a brake pad 13 and a unit brake cylinder 14. The brake pad 13 and the brake disc 11 form a certain gap, and the lever system 12 acts on the gate 13. When braking, the unit brake cylinder 14 converts the pressure of the compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com