Railway wagon swing bolster spring breaking fault image identification method

A railway freight car and image recognition technology, applied in the field of fault identification and railway freight car fault identification, can solve the problems of heavy workload of staff and missed inspections, and achieve the effect of improving accuracy, reducing false alarms, and improving stability and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

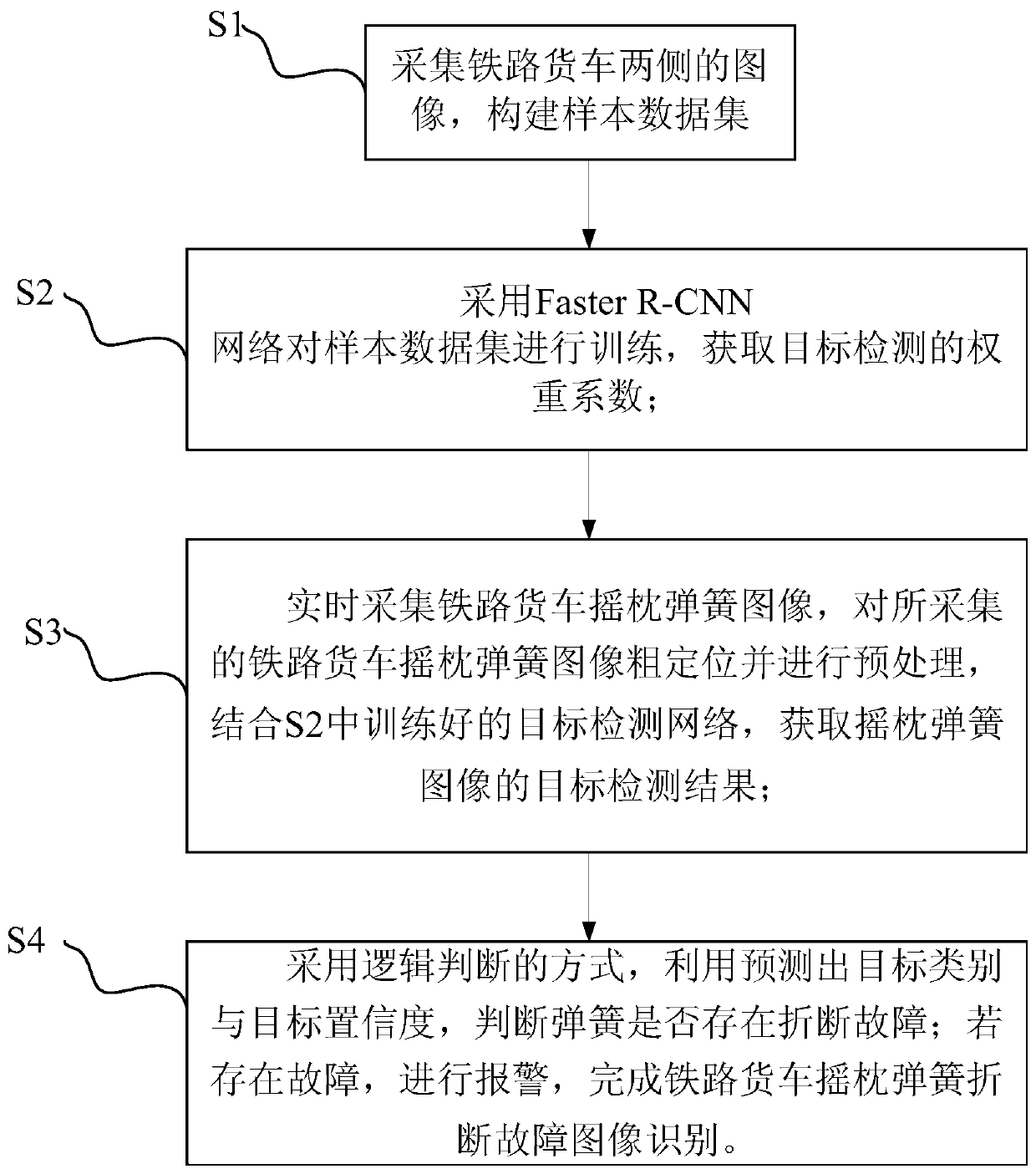

[0032] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode, a method for fault image recognition of railway freight car bolster spring breakage described in this embodiment mode, the method specifically includes:

[0033] S1. Collect images on both sides of the railway wagon to construct a sample data set;

[0034] The sample data set includes a rough positioning component grayscale image data set and a component breaking mark data set;

[0035] S2. Using the Faster R-CNN network to train the sample data set to obtain the weight coefficient of the target detection;

[0036] S3, collect the bolster spring image of the railway freight car in real time, roughly locate and preprocess the collected bolster spring image of the railway freight car, and combine the trained Faster R-CNN network in S2 to obtain the target detection result of the bolster spring image; The target detection result includes target category and target confiden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com