Roller bearing grinder for railway freight car wheel pair

A technology for rolling bearings and railway wagons, applied to grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high power consumption, frequent replacement, and large wear, and achieve reduced power consumption, improved versatility, and reduced wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

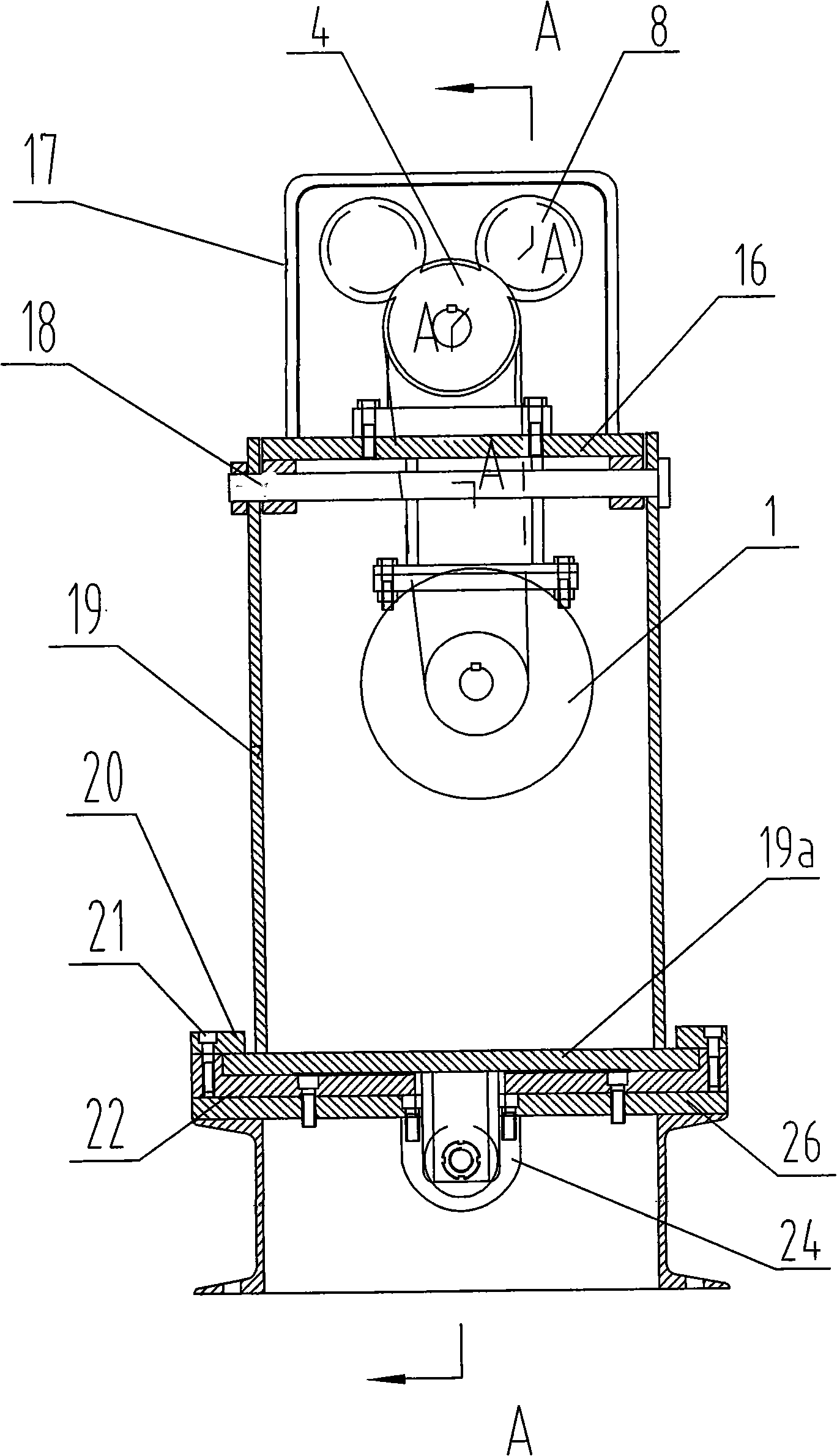

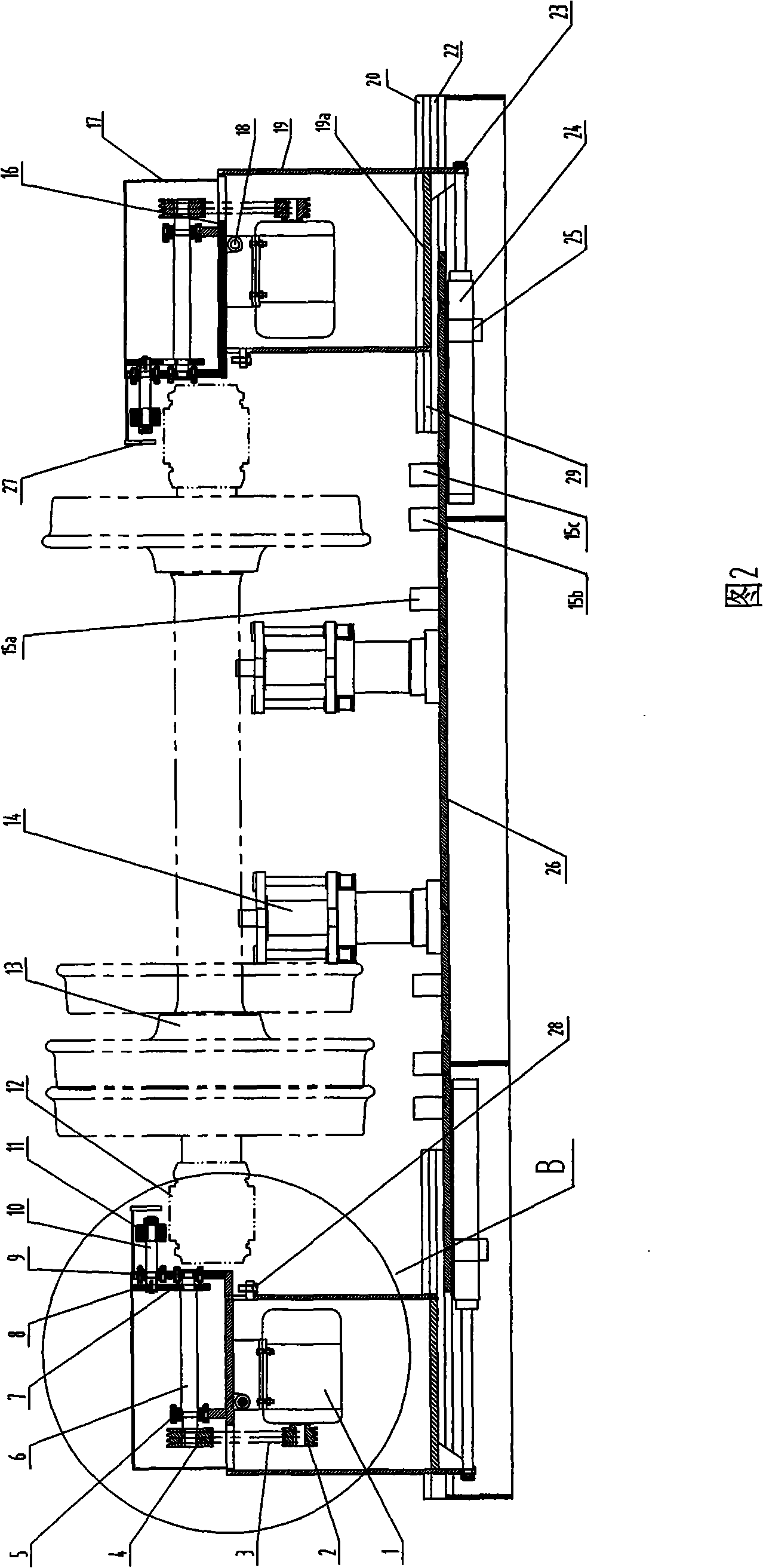

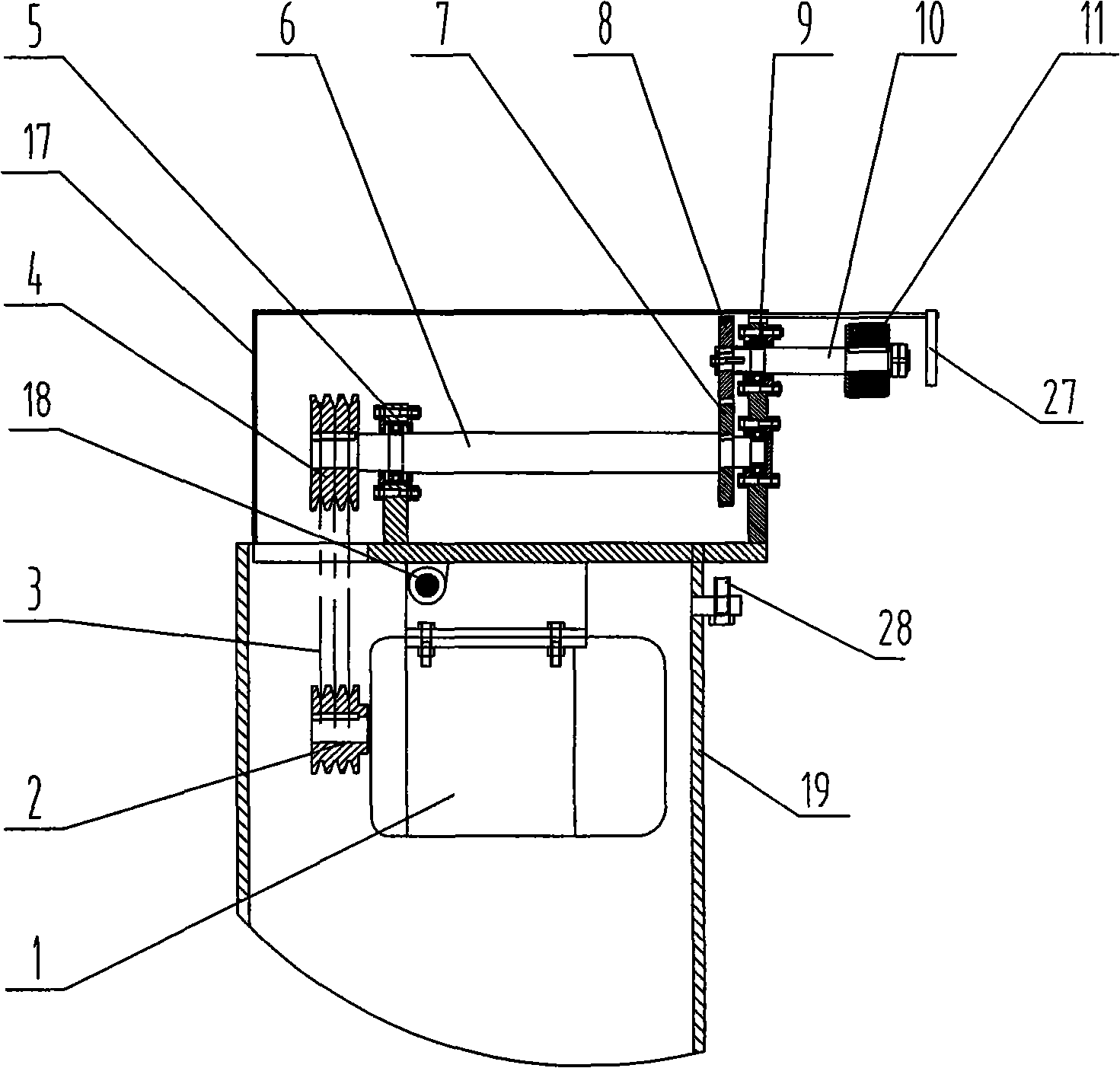

[0012] Such as figure 1 As shown in Fig. 2, three pairs of guide rails 15a, 15b and 15c of different gauges are provided on the machine base 26, and two top wheel oil cylinders 14 for lifting the wheels, two roller bearings 12 on the wheels 13 carry out The running-in device of running-in is symmetrically installed on the frame 19 at two ends of the machine base 26; superior. Each running-in device comprises a motor 1, a transmission and two flexible friction transmission wheels 11, the transmission is made up of pulleys 2 and 4, a belt 3, a main transmission shaft 6, gears 7 and 8 and an output shaft 10, the main transmission shaft 6 and The output shaft 10 is respectively fixed on the slewing bracket 16 through the rolling bearings 5 and 9, the motor 1 is fixed under the slewing bracket 16, and is connected with the main transmission shaft through the pulley and the belt. The two output shafts 10 above the shaft are connected by transmission, and each friction transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com