Freight car special for multi-mode combined loading containers

A container and multi-mode technology, applied in the direction of trucks, railway car bodies, axle box lubrication, etc., can solve the problems of difficulty in fully utilizing the carrying capacity, large waste of vehicle transport capacity, and difficult loading, so as not to reduce transportation efficiency , Increase the number of boxes and container specifications, and reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with embodiment the present invention is further described.

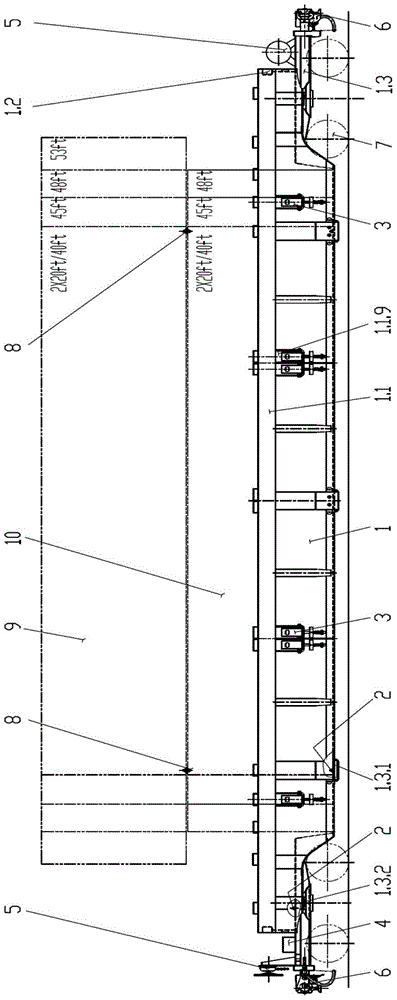

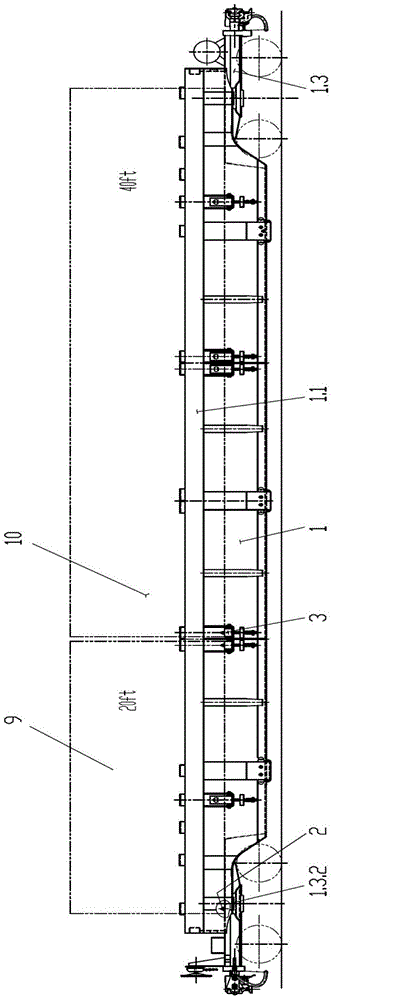

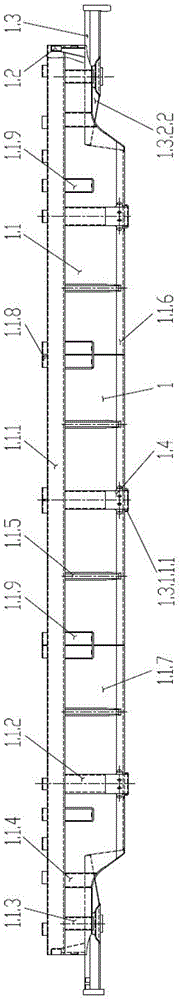

[0052] see figure 1 —6, multi-mode combined container special truck, including car body 1, vehicle positioning system 4, braking system 5, traction and suspension device 6 and bogie 7; car body 1 includes side wall 1.1, end wall 1.2 and chassis 1.3; side wall 1.1 includes upper beam 1.1.1, main column 1.1.2, pillow column 1.1.3, auxiliary column 1.1.5, lower beam 1.1.6, side wall panel 1.1.7; Plate type locking mechanism 3, it comprises lock base plate 3.1, lock head 3.2, rotating pin shaft 3.3, lock base support base 3.4 and lock base positioning mechanism 3.5; The upper side beam 1.1.1 and the side wall panel 1.1.7 are assembled and welded as one, and the lock seat plate 3.1 is connected with the lock seat support seat 3.4 through the rotating pin shaft 3.3; the bottom frame 1.3 includes the concave bottom frame 1.3.1 and the bottom of the pillow frame 1.3.2; the two ends and the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com