Waste sintered brick powder non-sintered foamed ceramsite and preparation method

A technology of brick powder and ceramsite, which is applied in the field of solid waste utilization and non-fired ceramsite, can solve the problems of affecting material properties, efflorescence, and excessive alkali content, so as to reduce production costs, improve utilization rate, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

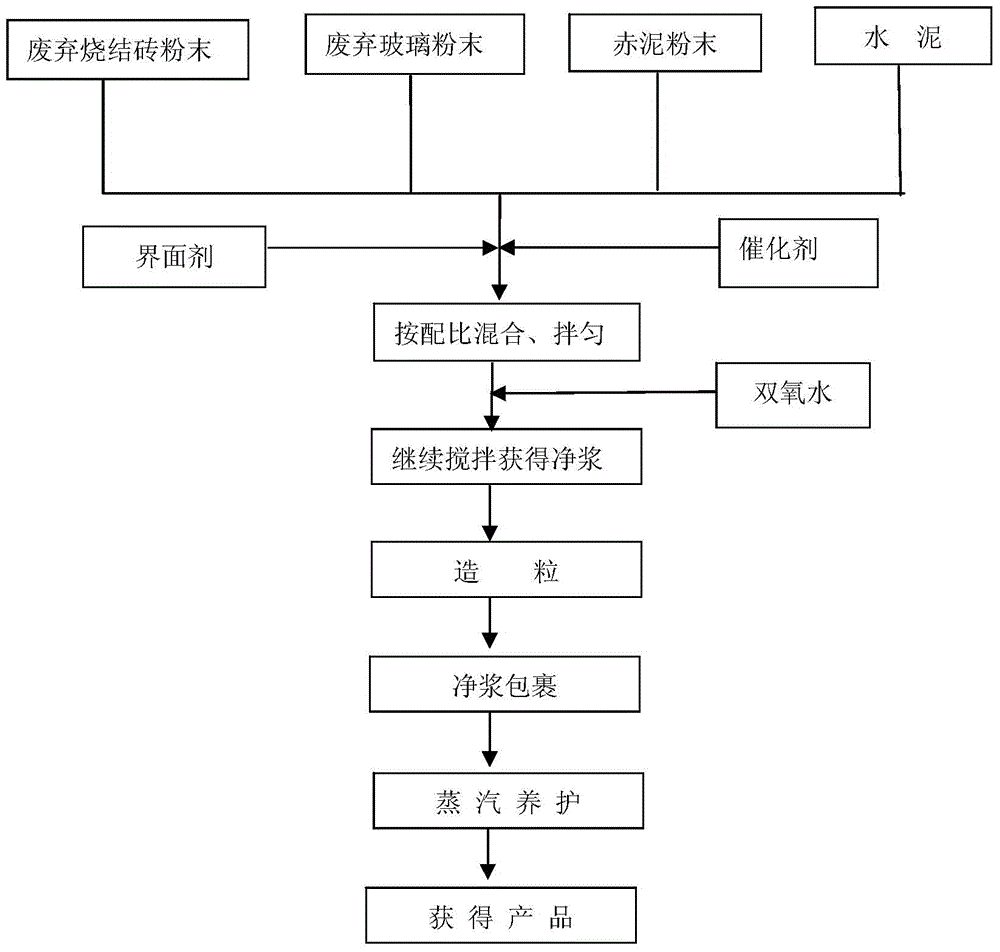

[0016] Example 1. Grind waste fired bricks and glass powder to 200 meshes, mix raw materials according to the proportion of waste fired brick powder 45%, glass powder 20%, cement 20%, red mud 15%, and add 1% interface agent (rubber powder) and 0.1% catalyst (manganese dioxide), and stir them evenly with a mixer; take 10% hydrogen peroxide solution of the total mass of waste fired brick powder, glass powder, red mud, and cement, and mix it according to w / t=0.4 Dilute, add to the mixer and stir, add the evenly stirred mixture into the granulator, process it into round particles with a diameter of 13mm, prepare a certain concentration of clean slurry, and wrap a layer of cement clean slurry on the ceramsite; The pellets were steam-cured for 6 hours under the conditions of 90° C. and 90% humidity to obtain the product. Density 835kg / m 3 , Strength 2.4MPa.

example 2

[0017] Example 2. Grind waste fired bricks and glass powder to 200 meshes, mix raw materials according to the proportion of waste fired brick powder 50%, glass powder 20%, cement 20%, red mud 10%, and add 1% interface agent (rubber powder) and 0.1% catalyst (manganese dioxide), and stir them evenly with a mixer; take 10% hydrogen peroxide solution of the total mass of waste fired brick powder, glass powder, red mud, and cement, and mix it according to w / t=0.4 Dilute, add to the mixer and stir, add the evenly stirred mixture into the granulator, process it into round particles with a diameter of 13mm, prepare a certain concentration of clean slurry, and wrap a layer of cement clean slurry on the ceramsite; The pellets were steam-cured for 6 hours under the conditions of 90° C. and 90% humidity to obtain the product. Density 830kg / m 3 , Strength 2.5MPa.

example 3

[0018] Example 3. Grind waste fired bricks and glass powder to 200 meshes, mix raw materials according to the ratio of waste fired brick powder 55%, glass powder 15%, cement 15%, red mud 15%, and add 1% interface agent (rubber powder) and 0.1% catalyst (manganese dioxide), and stir them evenly with a mixer; take 10% hydrogen peroxide solution of the total mass of waste fired brick powder, glass powder, red mud, and cement, and mix it according to w / t=0.4 Dilute, add to the mixer and stir, add the evenly stirred mixture into the granulator, process it into round particles with a diameter of 13mm, prepare a certain concentration of clean slurry, and wrap a layer of cement clean slurry on the ceramsite; The pellets were steam-cured for 6 hours under the conditions of 90° C. and 90% humidity to obtain the product. Density 842kg / m 3 , Strength 2.08MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com