Two-phase supply cyclic semidry process desulfuration method and system

A semi-dry desulfurization and feeding technology, which is applied in the field of flue gas desulfurization, can solve problems such as inability to desulfurize, short life, and influence on desulfurization efficiency, and achieve the effects of improving desulfurization efficiency, reducing consumption, and expanding the range of adaptable loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

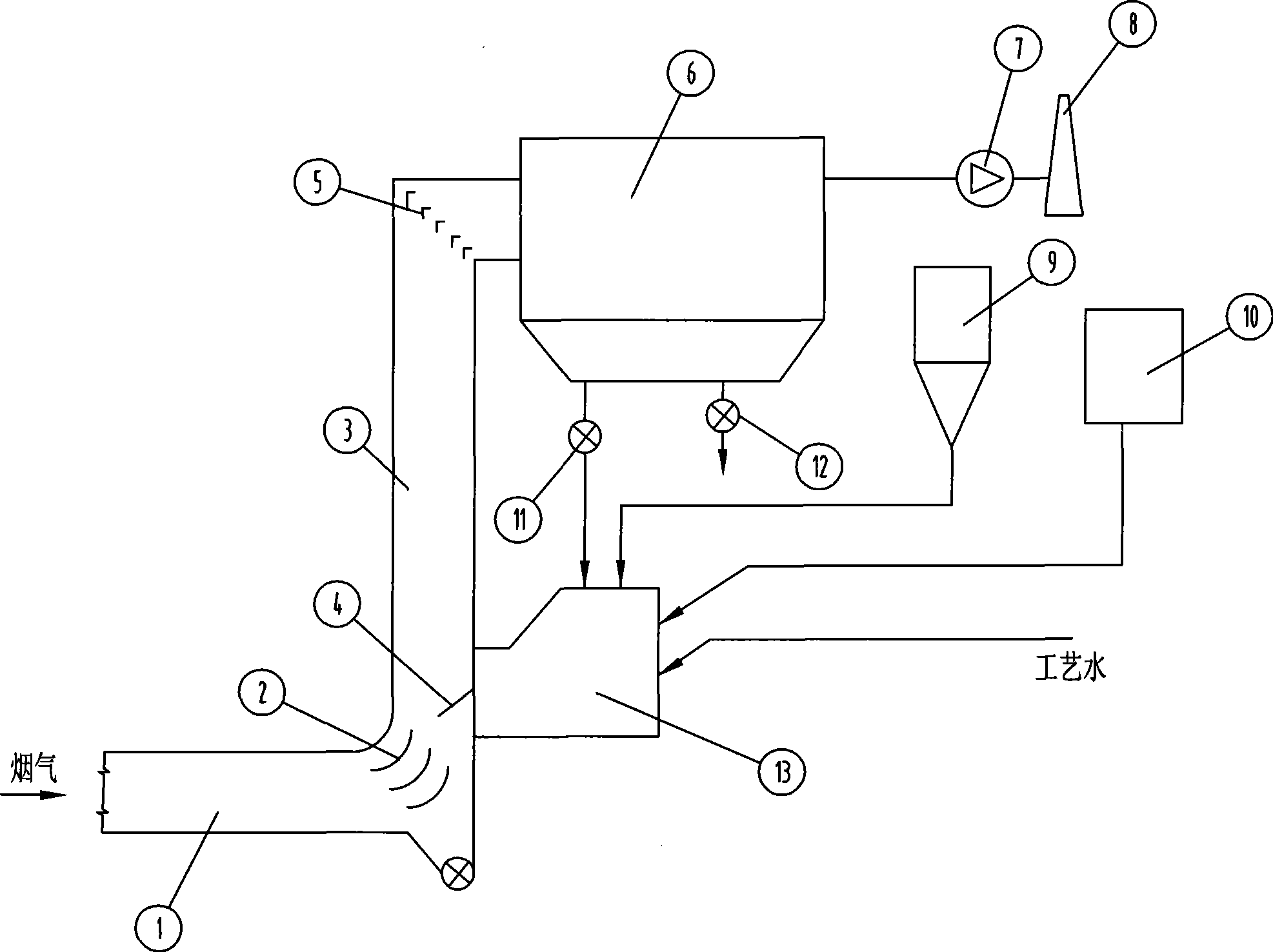

[0020] refer to figure 1 , a circulating semi-dry desulfurization system, including a horizontal flue 1, a reactor 3, a dust collector 6, an induced draft fan 7 and a chimney 8 connected in sequence, and a conditioner 13, the outlet of the lower end of the dust collector 6 is connected to the conditioner On the conditioner 13, the dry powder absorbent bin 9 and the slurry tank 10 are also connected to the conditioner 13, and the outlet of the conditioner 13 is connected to the reactor 3. The circulation feeding valve 11 is used to control the entry of desulfurization ash under the dust collector 6, and the connection between the horizontal flue 1 and the reactor 3 is provided with a deflector 2 to guide the flue gas into the reactor 3, and the reactor 3 and the dust collector 6 A reactor outlet guide plate 5 is also provided at the junction of the reactor for flow guide. The reactor 3 is directly connected with the conditioner 13, and the material guide plate 4 is provided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com