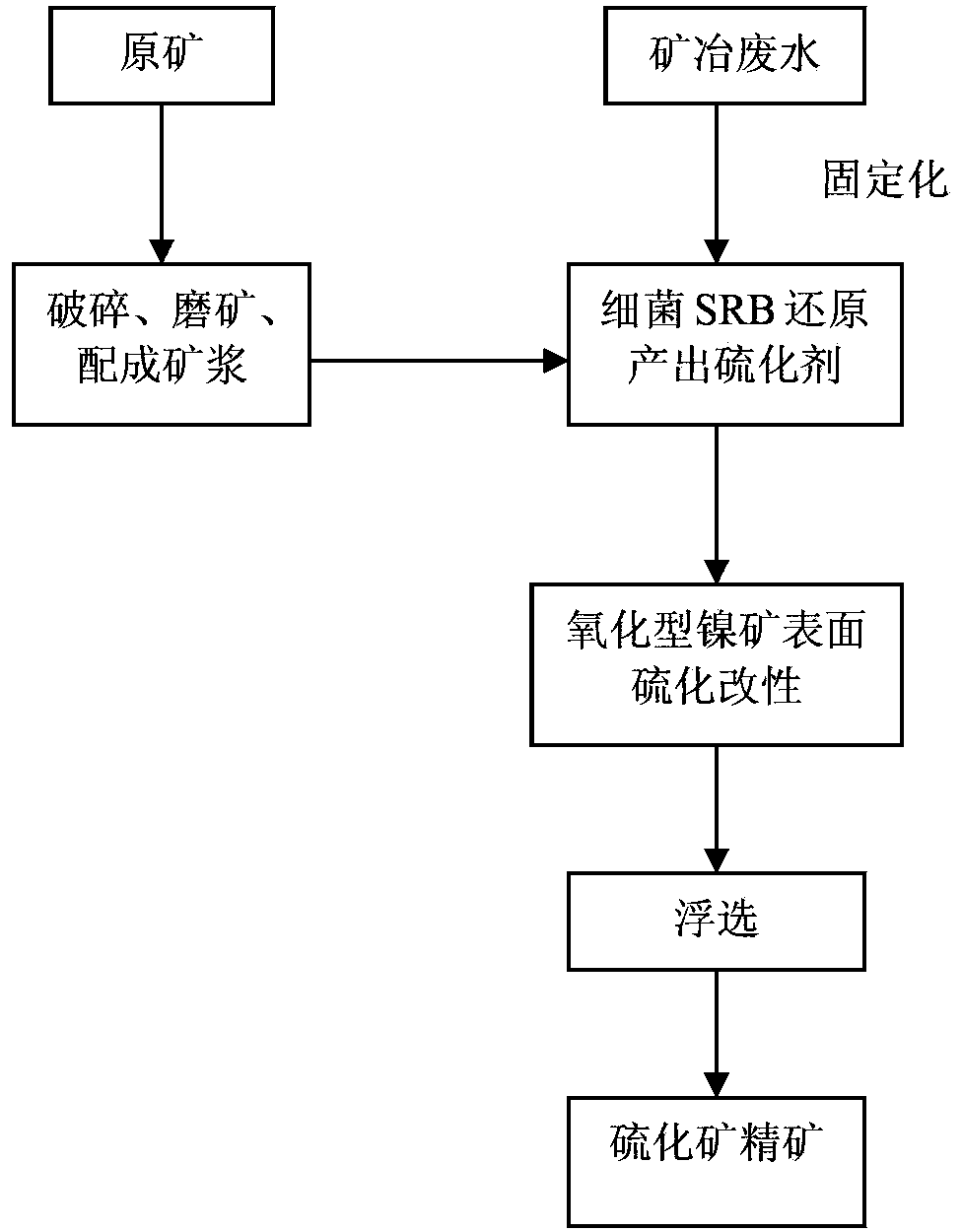

Method for vulcanizing low-grade oxidized nickel ore with microbiological method

A microbial method and oxidation-type technology, applied in the field of microorganisms, can solve the problems of difficult expansion of application range, large consumption of sodium sulfide, high production costs, etc., and achieve good industrial application prospects, low processing costs, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 2 kg of an oxidized nickel ore, crush and grind it to obtain a slurry with a particle size of -200 mesh, accounting for 80%, and make it into a slurry with a solid content of 20%. The sulfate-reducing bacteria-producing hydrogen sulfide reactor is filled with polyurethane foam as an immobilized carrier, and the inoculation amount of bacteria is 20%-50% (V / V). Use a peristaltic pump to continuously pump it from the bottom of the reactor, and the inflow flow rate is 1~3mL min -1 , the concentration of sulfate in the influent medium is gradually increased periodically (the conversion rate of sulfate reaches more than 80%), and each increase is 0.5g L -1 , the COD (Chemical oxygen demand, chemical oxygen demand) in the medium also increases accordingly, maintaining the COD / SO in the influent medium 4 2- The ratio is constant. When the sulfate-reducing bacteria hydrogen sulfide production unit is successfully started and runs stably, and the total sulfide production ...

Embodiment 2

[0026] Take a certain amount of oxidized nickel ore, crush and grind it to obtain a slurry with a particle size of -250 mesh, accounting for 70%, and make it into a slurry with a solid content of 20%. Sulfate-reducing bacteria-producing hydrogen sulfide reactors are filled with modified activated carbon materials as immobilized carriers, and the inoculation amount of bacteria is 10%~30% (V / V). Use a peristaltic pump to continuously pump it from the bottom of the reactor, and the inflow flow rate is 1~3mL min -1 , the concentration of sulfate in the feed medium is gradually increased periodically (the removal rate of sulfate reaches more than 80%), when the total sulfide production is continuously stable above about 400mg / L, the outlet liquid in the reactor is removed into the vulcanization reactor for chemical reaction. Control reaction temperature is 40~70 ℃, reaction time 1 hour, nickel flotation recovery rate is 50%~70%.

Embodiment 3

[0028] Take a certain amount of oxidized nickel ore, crush and grind the ore to make the pulp particle size -300 mesh, accounting for 90%, and make it into a pulp of 20% (solid content). The sulfate-reducing bacteria-producing hydrogen sulfide reactor is filled with polyurethane foam as an immobilized carrier, and the inoculation amount of bacteria is 20%~40% (V / V). Use a peristaltic pump to continuously pump it from the bottom of the reactor, and the inflow flow rate is 2~3mL min -1, the concentration of sulfate in the feed medium is gradually increased periodically (the removal rate of sulfate reaches more than 80%), when the total sulfide production is continuously stable above about 400mg / L, the outlet liquid in the reactor is removed into the vulcanization reactor for chemical reaction. Control reaction temperature is 50~70 ℃, reaction time 1 hour, nickel flotation recovery rate is 50%~70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com