Low-temperature ceramic curing agent of red mud from Bayer process

A technology of Bayer red mud and low-temperature ceramics, applied in cement production, etc., can solve the problems of Bayer red mud stockpiling, dam collapse, dam crossing, etc., and achieve environmental protection, low cost, and solve safety problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0023] Aluminosilicate waste slag: 20 parts of yellow phosphorus slag, 50 parts of fly ash, 30 parts of blast furnace slag;

[0024] Industrial by-product gypsum: 20 parts of phosphogypsum, 130 parts of desulfurized gypsum;

[0025] Exciting materials: 50 parts of lime, 100 parts of carbide slag, 50 parts of kiln dust;

[0026] Water reducer: 2.0 parts of calcium lignosulfonate, 0.4 part of naphthalene sulfonate, 0.1 part of polycarboxylic acid;

[0027] Flocculant: 3.0 parts of polyaluminum sulfate, 1.5 parts of ferric chloride, 0.5 parts of polyacrylamide;

[0028] Retarder: 1.0 parts of borax, 0.5 parts of sodium phosphate, 0.5 parts of sodium fluoride, and 3 parts of calcium nitrate.

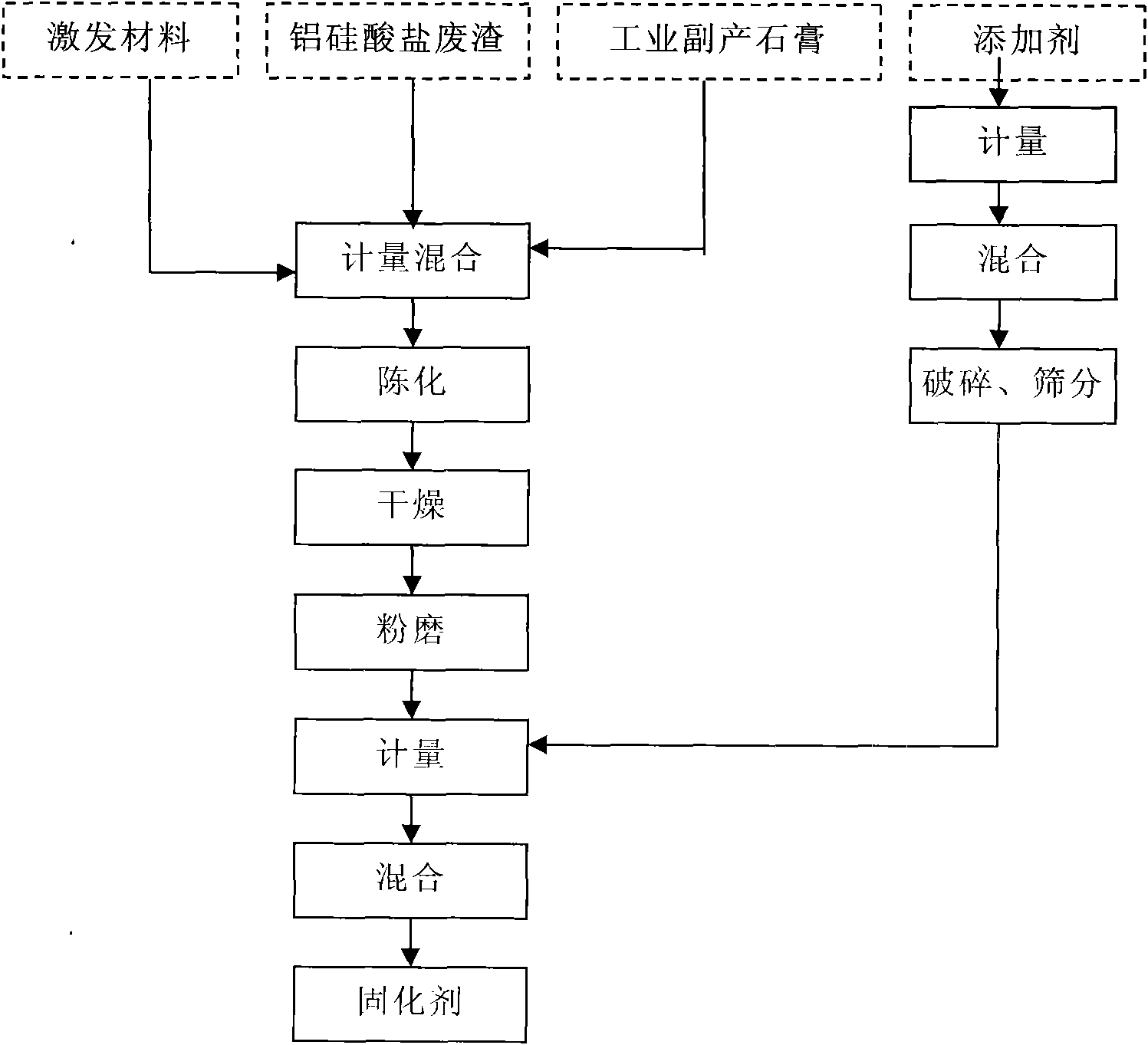

[0029] The production method of the low-temperature ceramic solidifying agent of Bayer process red mud described in the embodiment of the present invent...

Embodiment 2

[0035] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0036] Aluminosilicate waste residue: 20 parts of calcined tailings, 50 parts of calcined coal gangue, 30 parts of calcined red mud;

[0037] Industrial by-product gypsum: 10 parts of fluorine gypsum, 10 parts of citric acid gypsum;

[0038] Exciting materials: 30 parts of lime, 10 parts of carbide slag, 10 parts of kiln dust;

[0039] A kind of production method of the low-temperature ceramic solidifying agent of Bayer method red mud described in the embodiment of the present invention comprises the following steps:

[0040] Mix aluminosilicate waste slag, industrial by-product gypsum, and excitation materials according to the above ratio, age for 5 hours, and then dry. The test moisture content is 0.4%, put it into a ball mill for grinding, and the test powder fineness is 0.08mm , and the sieve residue is 3.0%, which becomes the product d...

Embodiment 3

[0043] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0044] Aluminosilicate waste slag: 50 parts of blast furnace slag, 40 parts of steel slag, 10 parts of thermal manganese slag;

[0045] Industrial by-product gypsum: 10 parts of wet-process manganese slag, 10 parts of lead-zinc slag, 100 parts of desulfurized gypsum;

[0046] Exciting materials: 50 parts of lime, 80 parts of carbide slag, 20 parts of kiln dust;

[0047] Water reducing agent: 0.2 parts of sodium lignosulfonate, 0.8 parts of sodium humate, 1.0 parts of polycarboxylic acid;

[0048] Flocculants: 1.3 parts of polymeric aluminum sulfate, 1.2 parts of polymeric iron sulfate;

[0049] Retarder: 0.5 parts of sodium fluoride, 2.0 parts of calcium nitrate;

[0050] A kind of production method of the low-temperature ceramic solidifying agent of Bayer method red mud described in the embodiment of the present invention comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com