Low-temperature ceramic curing agent of red mud from Bayer process

A Bayer process red mud and low-temperature ceramic technology, which is applied in cement production and other directions, can solve the problems of Bayer process red mud storage, dam collapse, cross-dam and other problems, and achieves a solution that is beneficial to environmental protection, low cost, and solves safety problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0023] Aluminosilicate waste slag: 20 parts of yellow phosphorus slag, 50 parts of fly ash, 30 parts of blast furnace slag;

[0024] Industrial by-product gypsum: 20 parts of phosphogypsum, 130 parts of desulfurized gypsum;

[0025] Exciting materials: 50 parts of lime, 100 parts of carbide slag, 50 parts of kiln dust;

[0026] Water reducer: 2.0 parts of calcium lignosulfonate, 0.4 part of naphthalene sulfonate, 0.1 part of polycarboxylic acid;

[0027] Flocculant: 3.0 parts of polyaluminum sulfate, 1.5 parts of ferric chloride, 0.5 parts of polyacrylamide;

[0028] Retarder: 1.0 parts of borax, 0.5 parts of sodium phosphate, 0.5 parts of sodium fluoride, and 3 parts of calcium nitrate.

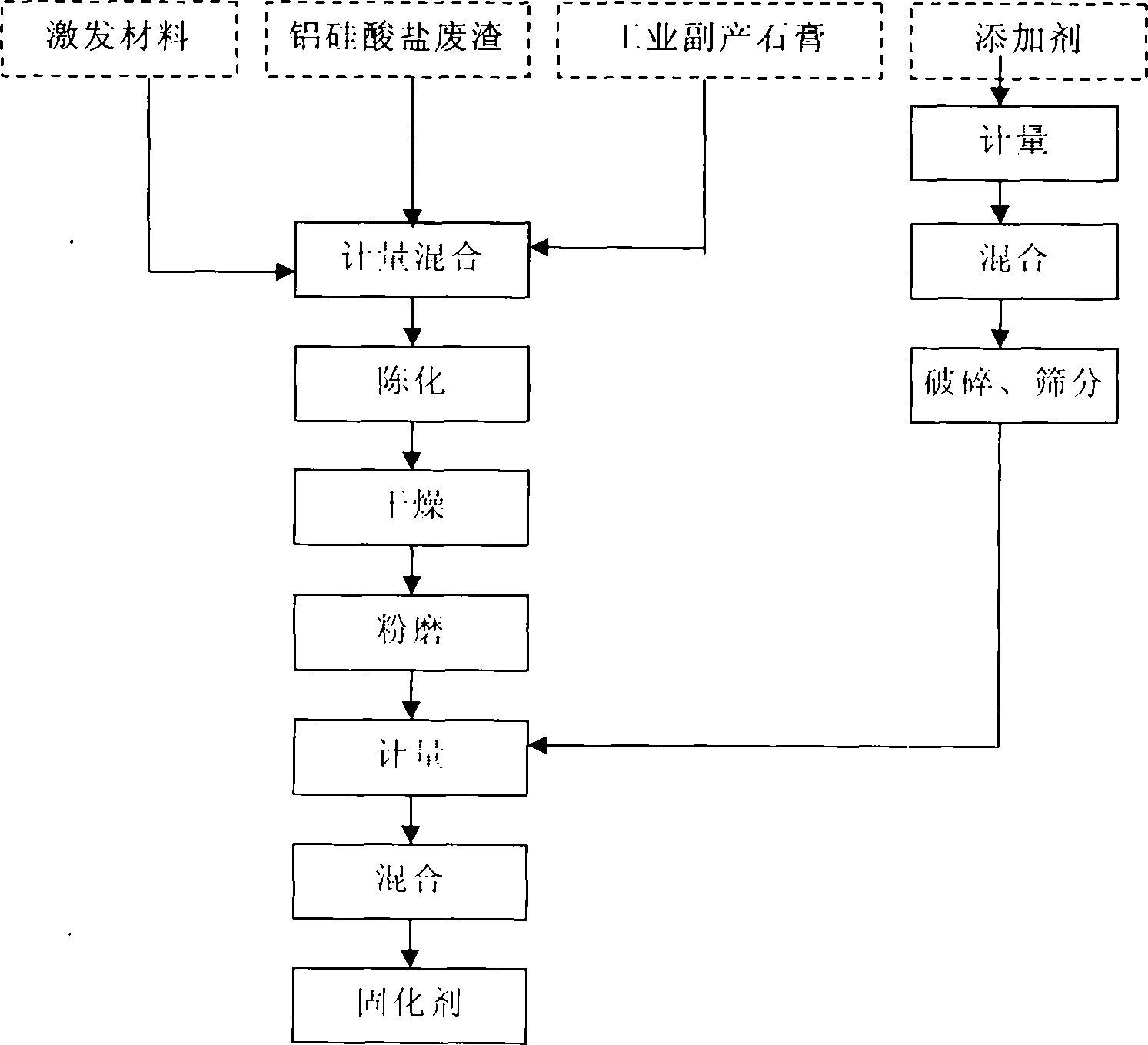

[0029] The production method of the low-temperature ceramic solidifying agent of Bayer process red mud described in the embodiment of the present invent...

Embodiment 2

[0035] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0036] Aluminosilicate waste residue: 20 parts of calcined tailings, 50 parts of calcined coal gangue, 30 parts of calcined red mud;

[0037] Industrial by-product gypsum: 10 parts of fluorine gypsum, 10 parts of citric acid gypsum;

[0038] Exciting materials: 30 parts of lime, 10 parts of carbide slag, 10 parts of kiln dust;

[0039] A kind of production method of the low-temperature ceramic solidifying agent of Bayer method red mud described in the embodiment of the present invention comprises the following steps:

[0040] Mix aluminosilicate waste slag, industrial by-product gypsum, and excitation materials according to the above ratio, age for 5 hours, and then dry. The test moisture content is 0.4%, put it into a ball mill for grinding, and the test powder fineness is 0.08mm , and the sieve residue is 3.0%, which becomes the product d...

Embodiment 3

[0043] A low-temperature ceramic curing agent for Bayer process red mud, prepared from the following raw materials in parts by weight:

[0044] Aluminosilicate waste slag: 50 parts of blast furnace slag, 40 parts of steel slag, 10 parts of thermal manganese slag;

[0045] Industrial by-product gypsum: 10 parts of wet-process manganese slag, 10 parts of lead-zinc slag, 100 parts of desulfurized gypsum;

[0046] Exciting materials: 50 parts of lime, 80 parts of carbide slag, 20 parts of kiln dust;

[0047] Water reducing agent: 0.2 parts of sodium lignosulfonate, 0.8 parts of sodium humate, 1.0 parts of polycarboxylic acid;

[0048] Flocculants: 1.3 parts of polymeric aluminum sulfate, 1.2 parts of polymeric iron sulfate;

[0049] Retarder: 0.5 parts of sodium fluoride, 2.0 parts of calcium nitrate;

[0050] A kind of production method of the low-temperature ceramic solidifying agent of Bayer method red mud described in the embodiment of the present invention comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com