Method for preparing titanium dioxide loaded biomass carbon aerogel material

A technology of carbon airgel and titanium dioxide, applied in chemical instruments and methods, chemical/physical processes, water pollutants, etc., can solve the problems of toxic oxidants and reducing agents, increase production costs, limit practical applications, etc., and achieve low cost , easy to operate, rich in raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

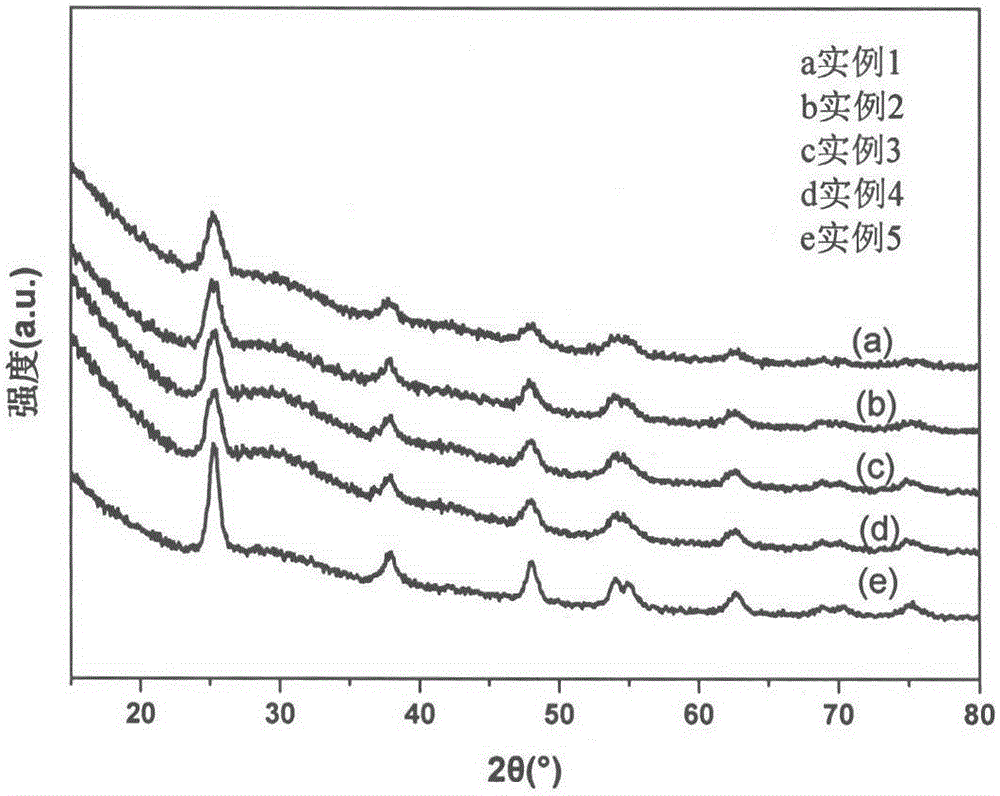

Embodiment 1

[0030] Cut the watermelon rind into 2cm*2cm*4cm size, put it into the reactor for hydrothermal reaction at 180°C for 20 hours, after the reaction is completed, the carbon-based wet gel is obtained, and the carbon-based wet gel is frozen in the refrigerator for 24 hours , to obtain a solid sample whose internal moisture is uniformly frozen, and dry the sample in a freeze dryer at -55°C for 12 hours to obtain a biomass carbon airgel material.

[0031] Weigh 0.03g Ti(SO4)2 and dissolve it in 20mL distilled water, ultrasonically oscillate until it is completely dissolved, then add 0.04g biomass carbon aerogel to the above solution, stir for 30min and transfer to 25mL polytetrafluoroethylene stainless steel The reaction kettle was kept at 200°C for 12 hours, and the hydrothermal product was obtained after natural cooling. The obtained samples were washed three times with distilled water and ethanol respectively, and then the samples were placed in a vacuum drying oven at a controll...

Embodiment 2

[0033] Cut the watermelon rind into 2cm*2cm*4cm size, put it into the reactor for hydrothermal reaction at 190°C for 16 hours, after the reaction is completed, the carbon-based wet gel is obtained, and freeze the carbon-based wet gel in the refrigerator for 24 hours , to obtain a solid sample whose internal moisture is uniformly frozen, and dry the sample in a freeze dryer at -10°C for 24 hours to obtain a biomass carbon airgel material.

[0034] Weigh 0.0592g Ti(SO4)2 and dissolve it in 20mL distilled water, ultrasonically oscillate until it is completely dissolved, then add 0.04g biomass carbon aerogel to the above solution, stir for 30min and transfer to 25mL polytetrafluoroethylene stainless steel for reaction The kettle was kept at 185°C for 18 hours, and the hydrothermal product was obtained after natural cooling. The obtained samples were washed three times with distilled water and ethanol respectively, and then the samples were placed in a vacuum drying oven at a contr...

Embodiment 3

[0036] Cut the watermelon rind into 2cm*2cm*4cm size, put it into the reactor for hydrothermal reaction at 200°C for 12 hours, after the reaction is completed, the carbon-based wet gel is obtained, and freeze the carbon-based wet gel in the refrigerator for 24 hours , to obtain a solid sample whose internal moisture is uniformly frozen, and dry the sample in a freeze dryer at -35°C for 24 hours to obtain a biomass carbon airgel material.

[0037] Weigh 0.12g Ti(SO4)2 and dissolve it in 20mL distilled water, ultrasonically oscillate until it is completely dissolved, then add 0.04g biomass carbon aerogel to the above solution, stir for 30min and transfer to 25mL polytetrafluoroethylene stainless steel The reaction kettle was kept at 180°C for 12 hours, and the hydrothermal product was obtained after natural cooling. The obtained samples were washed three times with distilled water and ethanol respectively, and then the samples were placed in a vacuum drying oven at a controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com