Preparation method and application of modified zeolite

A modified zeolite, modified technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, water/sludge/sewage treatment, etc., can solve the problem of rapid water quality changes, toxicity and carcinogenicity, sources and pollutant components Complicated problems, to achieve the improvement of water environment and the effect of high concentration removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A kind of modified zeolite and its preparation method and application

[0040] (1) Preparation method

[0041] 1) Artificial zeolite sample pretreatment: put the artificial zeolite sample in 400ml of distilled water, add 1-2 drops of dilute hydrochloric acid and shake it to neutralize the residual alkaline substances in the pores of the zeolite, wash it repeatedly until it is neutral, and then filter it. Tumble dry low.

[0042] 2) Mix HDTMA and deionized water at a ratio of 1:6 (m:m), and prepare an organic modification solution after ultrasonic stirring.

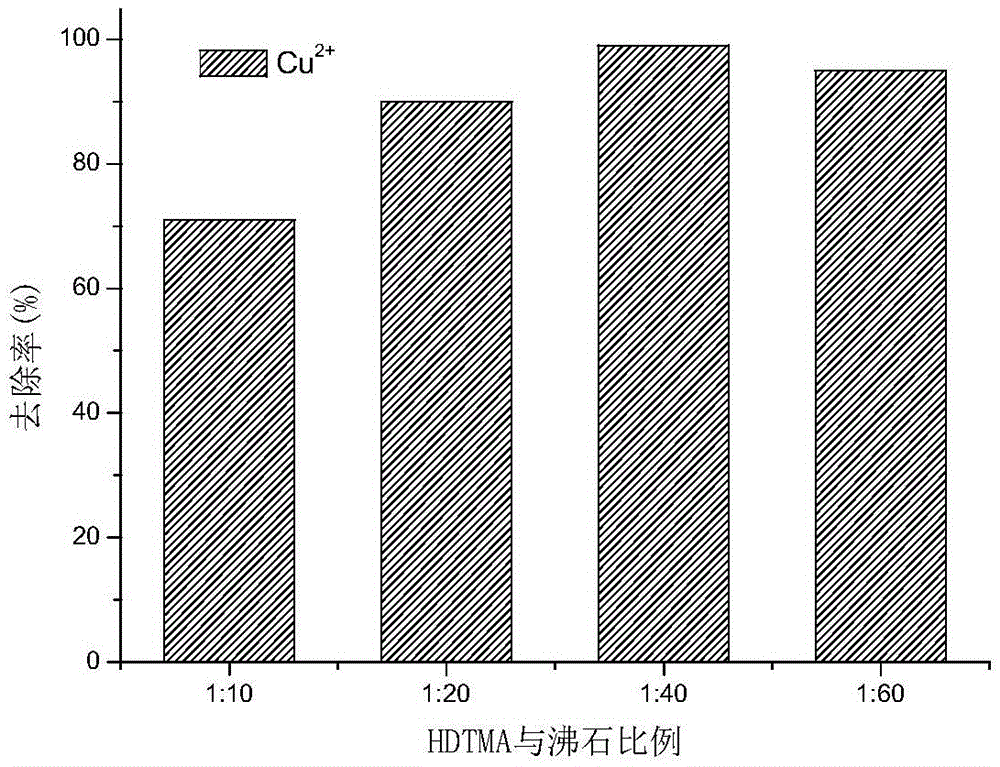

[0043] 3) Add artificial zeolite samples to the organic modification solution, the mass ratio of HDTMA to zeolite is 1:10, 1:20, 1:40, 1:60 respectively, after mixing, shake at room temperature for 30 hours, and wash repeatedly with distilled water to neutral, filter and separate to obtain a filter cake, and dry it at 60°C to obtain an organically modified zeolite.

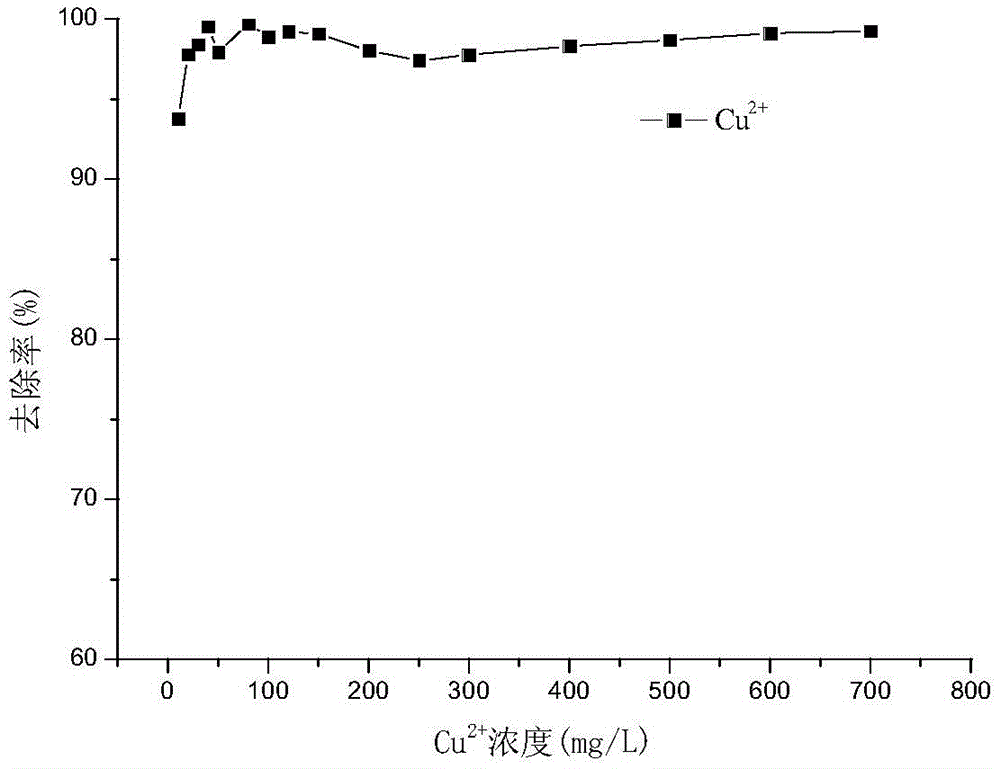

[0044] (2) Application 1

[0045...

Embodiment 2

[0050] Embodiment 2 A kind of modified zeolite and its preparation method and application

[0051] (1) Preparation method

[0052] 1) Artificial zeolite sample pretreatment: put the artificial zeolite sample in 400ml of distilled water, add 1-2 drops of dilute hydrochloric acid and shake it to neutralize the residual alkaline substances in the pores of the zeolite, wash it repeatedly until it is neutral, and then filter it. Tumble dry low.

[0053] 2) Mix DTBA and deionized water at a ratio of 1:3 (m:m), and prepare an organic modification solution after ultrasonic stirring.

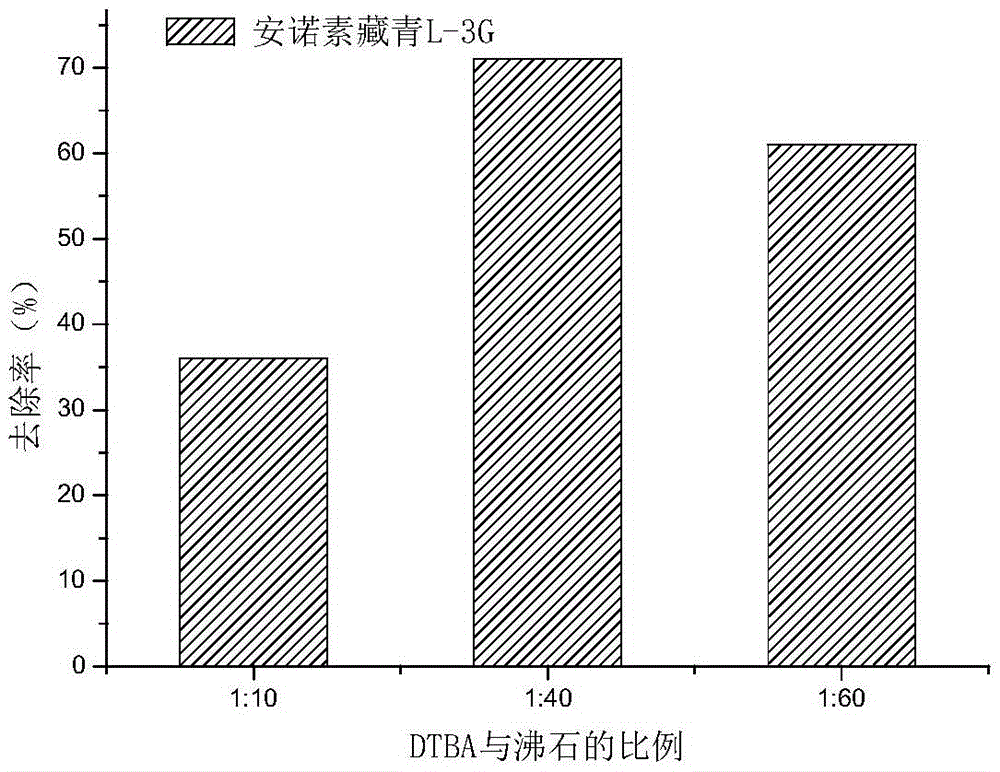

[0054] 3) Add artificial zeolite samples to the organic modification solution. The mass ratios of DTBA to zeolite are 1:10, 1:40, and 1:60 respectively. After mixing, shake at room temperature for 30 hours, and wash repeatedly with distilled water until neutral. Filter and separate to obtain a filter cake, and dry it at 70° C. to obtain an organically modified zeolite.

[0055] (2) Application

[005...

Embodiment 3

[0058] Embodiment 3 A kind of modified zeolite and its preparation method and application

[0059] (1) Preparation method

[0060] 1) Artificial zeolite sample pretreatment: put the artificial zeolite sample in 400ml of distilled water, add 1-2 drops of dilute hydrochloric acid and shake it to neutralize the residual alkaline substances in the pores of the zeolite, wash it repeatedly until it is neutral, and then filter it. Tumble dry low.

[0061] 2) Mix HDTMA and deionized water at a ratio of 1:5 (m:m), and prepare an organic modification solution after ultrasonic stirring.

[0062] 3) Add artificial zeolite samples to the organic modification solution. The mass ratios of HDTMA to zeolite are 1:10, 1:40, and 1:60 respectively. After mixing, shake at room temperature for 30 hours, and wash repeatedly with distilled water until neutral. Filter and separate to obtain a filter cake, and dry it at 50° C. to obtain an organically modified zeolite.

[0063] (2) Application

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com