Method for resource treatment of phosphatized sludge

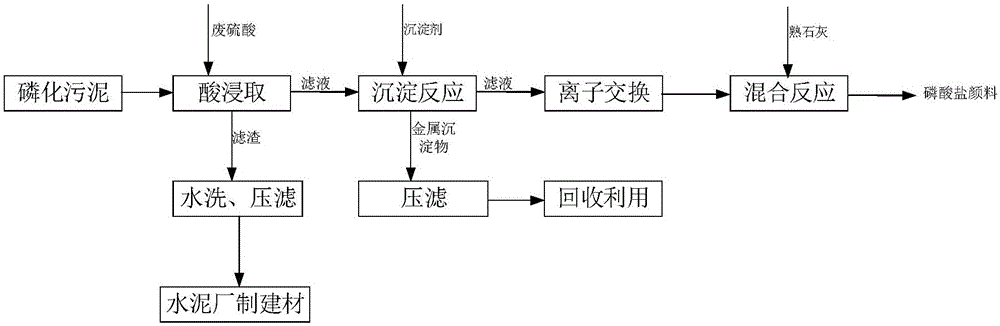

A technology of phosphating sludge and disposal method, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult treatment of phosphating wastewater and high treatment cost, and achieve low treatment cost , high processing efficiency, and the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Adopt the present invention to process the phosphating sludge that certain surface treatment enterprise of Jiangsu produces, and its operation condition is: adopt the waste sulfuric acid that acid concentration is 10%, the dosing ratio of phosphating sludge and waste sulfuric acid (each embodiment is) is: 1:5, stirring and mixing time is 1h. After the reaction, filter the filter residue and send it to the cement plant to make cement; the filtrate is added with a self-precipitating agent, and the ratio of the precipitating agent is NaOH:EDTA:FeSO 4 =2:3:0.5, the dosage of precipitant is 0.3% of the filtrate, and the reaction time is 1h; after passing through the anion exchange resin, the adsorbed saturated resin is eluted at a rate of 1.4 volume columns / hour, and in the eluent Add 10% slaked lime, react for 1.5h, and the reaction pH is 6 to form phosphate pigment.

Embodiment 2

[0044] Using the present invention to treat phosphating sludge from a chemical enterprise in Anhui, the operating conditions are as follows: waste sulfuric acid with an acid concentration of 5% is used, the dosing ratio of phosphating sludge to waste sulfuric acid is 1:15, and the mixing time is 2 hours , after the reaction, the filter residue is press-filtered and sent to the cement plant to make cement; the filtrate is added with a precipitant prepared by itself, and the precipitant configuration ratio is NaOH:EDTA:FeSO 4=6:1:1, the dosage of the precipitant is 1.2% of the filtrate, and the reaction time is 1.5h; after passing through the anion exchange resin, the adsorbed saturated resin is eluted at a rate of 1.8 volume columns / hour, and in the eluent Add 15% slaked lime internally, react for 2 hours, and the reaction pH is 7 to form phosphate pigment.

Embodiment 3

[0046] Using the present invention to treat phosphating sludge from a stainless steel production enterprise in Anhui, the operating conditions are as follows: waste sulfuric acid with an acid concentration of 20% is used, the ratio of phosphating sludge to waste sulfuric acid is 1:3, and the stirring and mixing time is 1.5h, after the reaction, filter the filter residue and send it to the cement plant to make cement; the filtrate is added with a self-precipitating agent, and the ratio of the precipitating agent is NaOH:EDTA:FeSO 4 =3:2:0.8, the dosage of the precipitant is 1.5% of the filtrate, and the reaction time is 0.5h; after passing through the anion exchange resin, the adsorbed saturated resin is eluted at a rate of 1.2 volume columns / hour, and in the eluent Add 20% slaked lime internally, react for 2.5 hours, and the reaction pH is 8 to form phosphate pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com