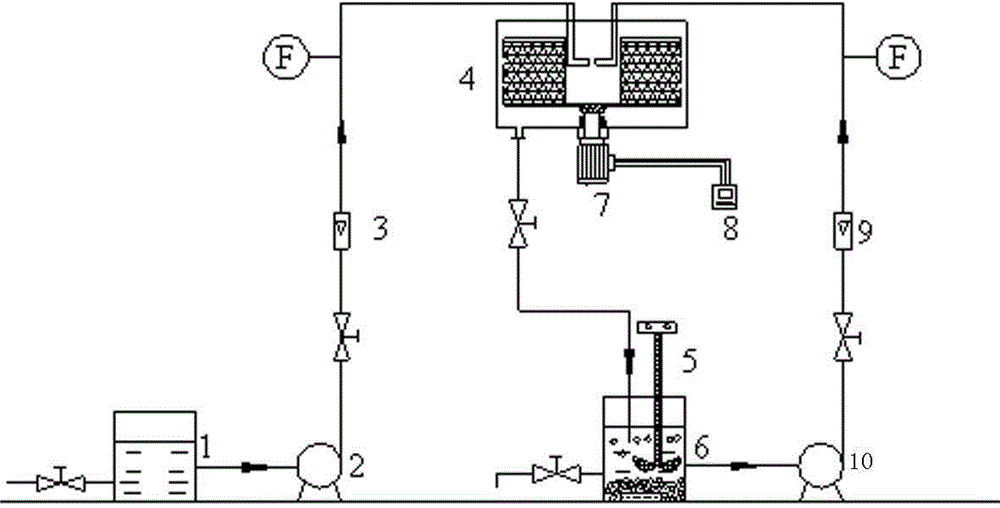

Method and device for treating wastewater by intensified micro-electrolysis-Fenton oxidation method

A technology for wastewater treatment and micro-electrolysis, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of shortened reaction time, reduced processing cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

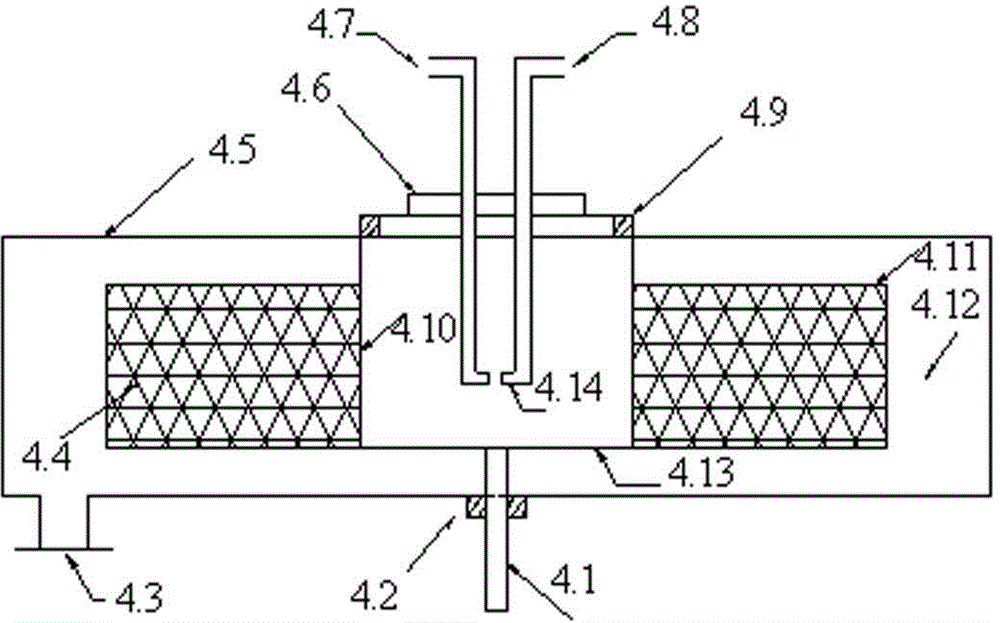

[0052] Example 1: Treatment of high-concentration printing and dyeing wastewater in a printing and dyeing factory. Wastewater is dark brown, pH is 2.5, color is 1200~1500 times, COD Cr 15000~32000mg / L. Micro-electrolysis was used to pretreat 1.5L of wastewater, the amount of iron powder added was 10g / L, the mass ratio of iron to carbon was Fe:C=0.5:1, the reaction time was 1.5h, and the stirring speed of the stirrer was 400r / min. , COD Cr Reduced by 30~50%, chromaticity decreased by about 20%; adjust the volume flow rate of micro-electrolyzed water and hydrogen peroxide to 5:1, the added H 2 o 2 The amount is about 0.05mol / L, COD after 2 hours of reaction Cr The removal rate reaches 60~70%, and the chroma removal rate reaches more than 95%. However, using the impingement flow-rotating packed bed (IS-RPB) as the liquid-liquid contact and reaction device, the two fluids of hydrogen peroxide and waste water collide with each other at an initial velocity of 0.5m / s, using corr...

Embodiment 2

[0053] Example 2: Treatment of dinitrotoluene (DNT) in waste water from a propellant and explosive factory. The initial concentration of dinitrotoluene in wastewater is 400mg / L, and the biochemical coefficient is only 0.1. Micro-electrolysis is used to treat 2.0L of wastewater. At pH=3, the amount of iron powder added is 20g / L, and the mass ratio of iron to carbon Fe: C=1.5:1, the reaction time is 2h, and the stirring speed of the stirrer is 200r / min, more than 80% of the nitro compounds are converted into aniline substances, and the flow meter is adjusted so that the volume flow ratio of the micro-electrolyzed water and hydrogen peroxide is 8 :1,H 2 o 2 The concentration is 0.03mol / L, the speed of impinging flow-rotating packed bed (IS-RPB) is 1500rpm, and the initial velocity of the two fluids of hydrogen peroxide and wastewater colliding is 3m / s. After 40min of degradation, the pollutant removal rate reaches 95% % or more; while the waste water that has not been pretreate...

Embodiment 3

[0054] Embodiment 3: Treatment of TNT wastewater. The concentration of trinitrotoluene in the wastewater is 100 mg / L, and the pH value is adjusted to 2.0 with dilute sulfuric acid. Take 2L of water sample, and use micro-electrolysis to pretreat the wastewater. The amount of iron powder added is 30g / L, the mass ratio of iron to carbon is 3:1, the stirring speed is 800r / min, and the reaction time is 1.5h. More than % of nitro compounds are converted into aniline substances, adjust the volume flow ratio of micro-electrolysis water and hydrogen peroxide to 10:1, the concentration of hydrogen peroxide is 0.01mol / L, and the speed of impinging flow-rotating packed bed device (IS-RPB) is 300rpm , Hydrogen peroxide and waste water collide with each other at an initial velocity of 10m / s. Stainless steel porous corrugated plate is used as filler. After 50 minutes of reaction, the removal rate of organic pollutants in waste water reaches 97%. The biochemical coefficient is above 0.5; whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com