Garbage pyrolysis sewage treatment system and garbage pyrolysis sewage treatment method

A sewage treatment system and sewage technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can be used as a sewage treatment technology in the solution process, and no one has proposed it. problems, to achieve the effect of saving water for coke quenching, reducing equipment investment and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

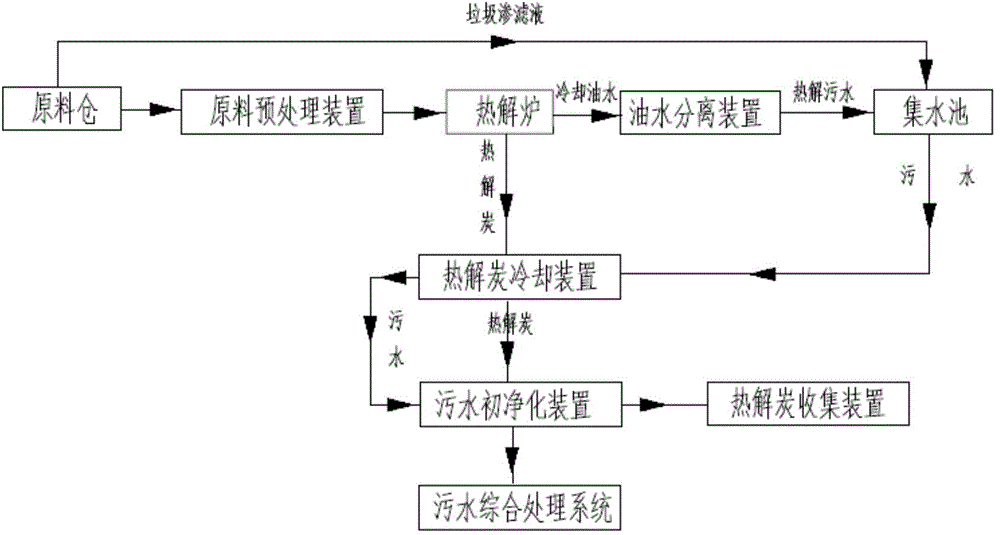

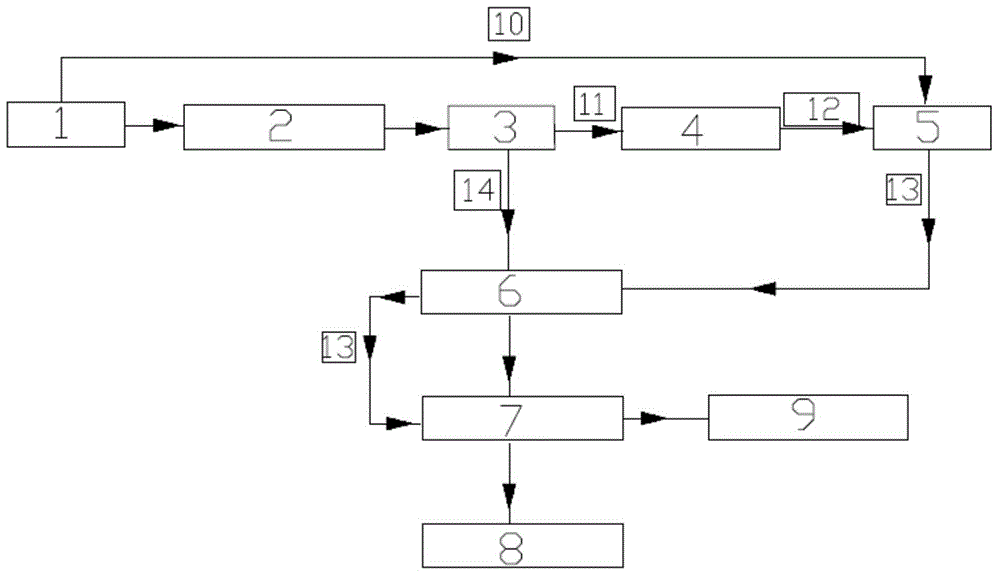

[0038] See figure 1 with figure 2 , a waste pyrolysis sewage treatment system, comprising a raw material warehouse 1, a raw material pretreatment device 2, a pyrolysis furnace 3, an oil-water separation device 4, a water collection tank 5, a pyrolytic carbon cooling device 6, a sewage primary purification device 7, and a comprehensive sewage Processing system 8, pyrolytic carbon collection device 9;

[0039] The raw material bin 1 is connected to the raw material pretreatment device 2 through the pipeline, and the raw material pretreatment device 2 is connected to the pyrolysis furnace 3 through the pipeline; the raw material bin 1 is connected to the sump 5 through the landfill leachate pipeline 10;

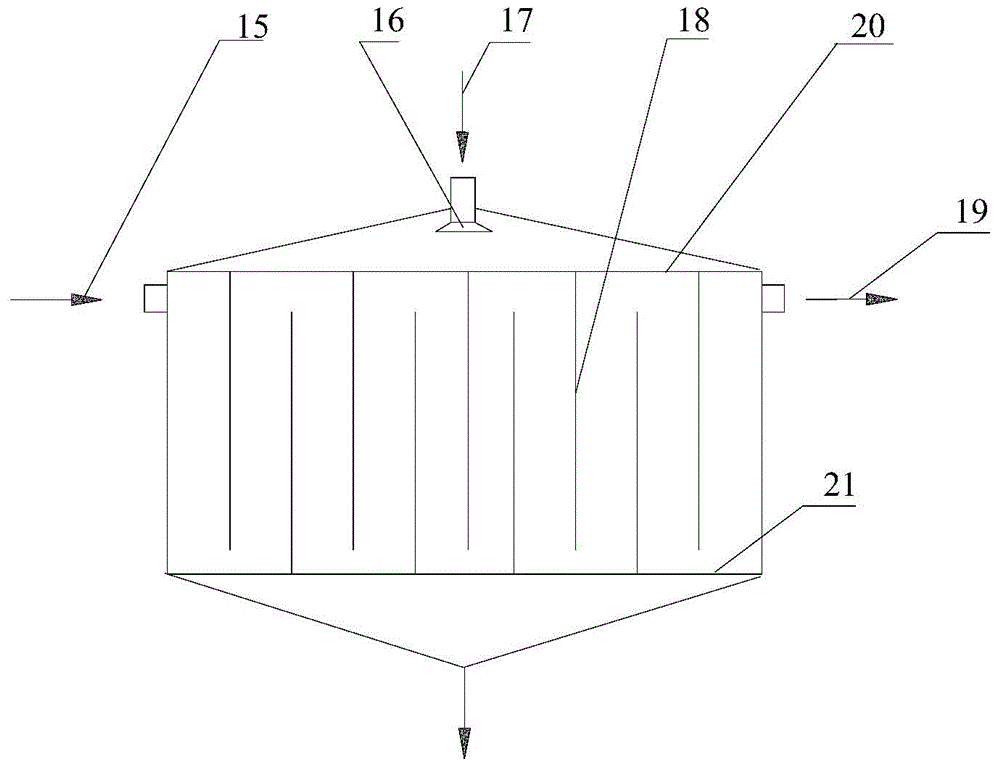

[0040] The upper part of the pyrolysis furnace 3 is provided with an oil and gas outlet, which is connected to the oil-water separation device 4 through the liquid oil-water pipeline 11; the sewage outlet of the oil-water separation device 4 is connected to the sump 5; The ch...

Embodiment 2

[0044] Use the device of embodiment 1 to carry out garbage pyrolysis sewage treatment, comprising steps:

[0045] 1) Raw material pretreatment: Household waste is weighed and stored in the raw material warehouse for 3 days, so that the moisture content of the waste is reduced by 10%; the landfill leachate generated by the accumulation is discharged into the sump; after accumulation, the inorganic impurities are separated from the waste for landfill ; Separation of metals for export and sales; separation of organic matter and combustibles and crushing, and pyrolysis in a pyrolysis furnace; after crushing, the particle size is 5mm-10mm;

[0046] 2) The crushed material enters through the feed port of the pyrolysis furnace, and is pyrolyzed in an environment where the built-in radiant tube of the pyrolysis furnace is isolated from oxygen. The material is pyrolyzed in an environment isolated from oxygen by a built-in radiant tube. The pyrolysis temperature is 600°C-700°C, and the ...

Embodiment 3

[0057] The system and process used are the same as in Example 2. The pyrolysis treatment parameters in this embodiment are: the treatment capacity is 20t / d, the pyrolysis charcoal is 8t / d, and the sewage is 10t / d. The pyrolytic carbon stays in the sewage primary purification device for 4 hours, and the ratio of waste pyrolytic carbon to sewage is 0.3:1 (w / w). The specific surface area of the pyrolytic charcoal obtained by pyrolysis is 270m 2 / g.

[0058] The temperature of pyrolyzed sewage and landfill leachate in the sump is 25°C.

[0059] Table 2 Comparison of influent and effluent water quality of primary sewage purification device

[0060]

[0061] As can be seen from Table 2, COD removal rate: 60%; BOD 5 The removal rate: 46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com