Treatment method of high-chroma chemical waste water

A chemical wastewater treatment method technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of high price, difficult regeneration, difficult to remove by biological methods, etc., and achieve improvement Efficiency and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

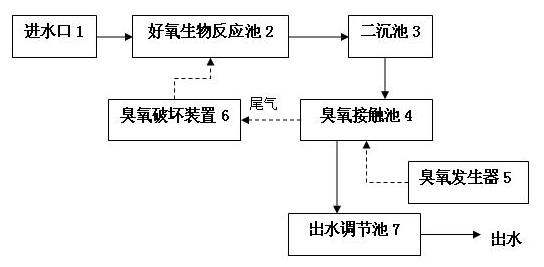

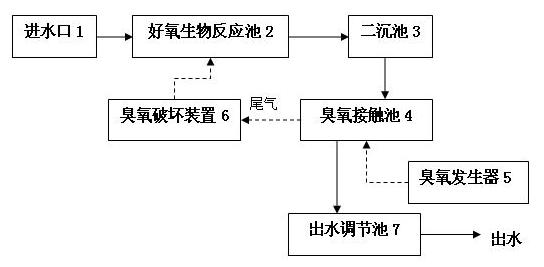

Image

Examples

Embodiment 1

[0034] In a treatment plant that treats 50,000 tons of industrial sewage per day, the water quality of chemical wastewater at the entrance 1 is COD518mg / L, BOD 5 248mg / L, after treatment in the aerobic biological reaction tank 2: the concentration of activated sludge is about 5000mg / L, the residence time is 24 hours, the dissolved oxygen concentration is 2-4mg / L; stay in the secondary sedimentation tank 3 for about 14 hours , the sludge reflux ratio is 150%; after ozone oxidation treatment, the water quality of the effluent regulating tank 7 is COD110mg / L, and the removal rate is 79%; BOD 5 248mg / L, the removal rate is 97%.

Embodiment 2

[0036] The same as the sewage treatment plant in Example 1, the water quality of the chemical wastewater at the inlet 1 is COD 475mg / L, BOD 5 220.3mg / L, after treatment in aerobic biological reaction tank 2: the concentration of activated sludge is about 5000mg / L, the residence time is 24 hours, and the dissolved oxygen concentration is 2-4mg / L; stay in secondary sedimentation tank 3 for about 14 hour, the sludge reflux ratio was 150%; after ozone oxidation treatment, the water quality of the effluent regulating tank 7 was COD86mg / L, and the removal rate was 82%; BOD 5 2.18mg / L, the removal rate is 99%.

Embodiment 3

[0038] Ozone continuous experiment, the volume of the reaction device is 100L. Ozone is produced by the ozone generator 5, with pure oxygen as the gas source, and the amount of ozone produced is 4g / h. Ozone is transferred into the water body in the form of small bubbles through the bottom aeration device. The ozone concentration in the tail gas is measured, and then discharged after being destroyed by high temperature.

[0039] Experiments were carried out on the effluent of the secondary sedimentation tank 3 of the sewage plant: the influent flow rate was 40L / h, and the water was kept for 24 minutes. After treatment, the chromaticity was reduced from 186 degrees to 15 degrees (Pt-Co), and the removal rate was 92%; COD was reduced from 78mg / L was reduced to 56mg / L, and the removal rate was 28%; the ozone concentration in the tail gas was 1.4g / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com