Integrated ozone and aeration biological filtering pool water treatment apparatus and method

A biological aerated filter and water treatment device technology, which is applied in the field of water treatment and advanced treatment of waste water containing refractory biodegradable organic matter, and can solve problems such as difficult construction and installation, unbalanced flow, increased floor space and operating costs. , to achieve the effect of reducing the difficulty of construction and installation, reducing power consumption and improving aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

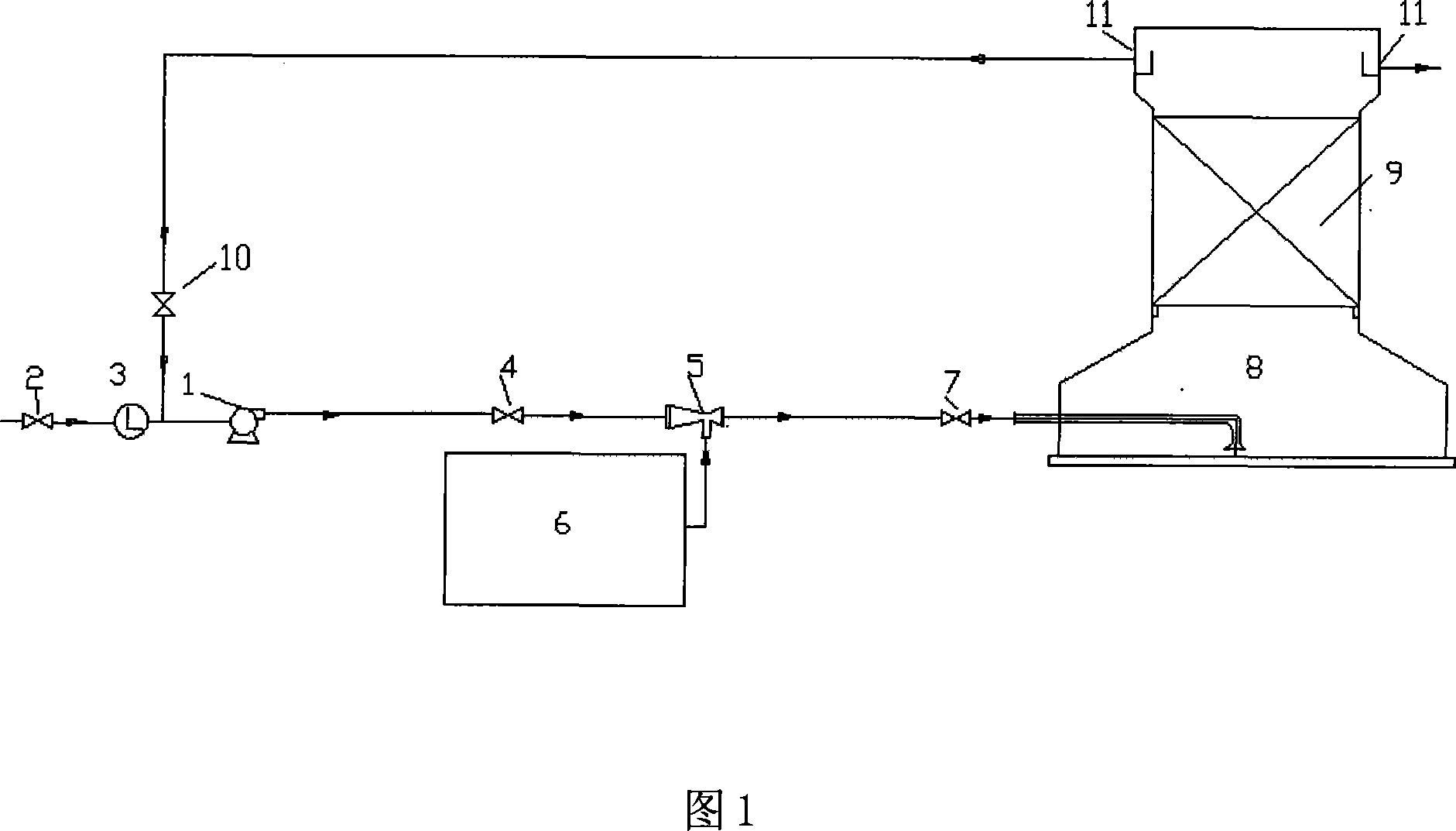

Embodiment 1

[0024] The ozone-biological aerated filter integrated water treatment method is used to carry out advanced treatment of the secondary biochemical effluent of a printing and dyeing factory wastewater, with a water volume of 5t / h. The Venturi tube used is made of stainless steel with a size of 50mm outer teeth. The ozone generating system adopts an ozone production rate of 300g / h. The model of the ozone generator is: SOZ-YW-300G. The oxygen content in the ozone gas is 19% of the total volume. The ozone contact reaction chamber is cylindrical and the total volume is about 10m 3 , the height is 1.2m, the radius is about 1.5m, and the total volume of the biological aerated filter is 20m 3 , the height is 4.4m, the radius is about 1.2m, the filter material is 3-5mm ceramsite, and the volume of ceramsite is 12m 3 . Firstly, through ozone pretreatment, the dosage of ozone is 0.5:1 mass ratio of ozone to COD, the reaction time of ozone in the contact oxidation chamber is 2 hours, and...

Embodiment 2

[0028] The ozone-biological aerated filter integrated water treatment method is used to carry out the depth of the secondary biochemical effluent of a paper mill wastewater, and the water volume is 10t / h. The Venturi tube used is made of stainless steel with a size of 50mm outer teeth. The ozone generation system adopts an ozone production capacity of 250g / h. The model of the ozone generator is: SOA-YW-250G. The oxygen contained in the ozone gas is 19% of the total volume. %, the ozone contact reaction chamber is cylindrical, with a total volume of about 10m 3 , the height is 0.8m, the radius is about 2m, and the total volume of the biological aerated filter is 30m 3 , the height is 3m, the radius is about 1.8m, the filter material is 3-5mm ceramsite, the volume of ceramsite is 18m 3 . Firstly, through ozone pretreatment, the dosage of ozone is 0.5:1 mass ratio of ozone to COD, the reaction time of ozone in the contact oxidation chamber is 1 hour, and the wastewater after oz...

Embodiment 3

[0032] The ozone-biological aerated filter integrated water treatment method is used to treat the polluted raw water of a waterworks, and the water volume is 10t / h. The Venturi tube used is made of stainless steel, with a size of 63mm outer teeth. The ozone generation system adopts an ozone generation rate of 12g / h. The model of the ozone generator is: SOZ-YW-12G, and the oxygen contained in the ozone gas is 20% of the total volume. %, the ozone contact reaction chamber is cylindrical, with a total volume of about 10m 3 , the height is 1.5m, the radius is about 1.5m, and the total volume of the biological aerated filter is 15m 3 , the height is 3.3m, the radius is about 1.2m, and the filter material is 3-5mm ceramsite. The dosage of ozone is that the mass ratio of ozone to COD is 0.1:1, and the reaction time of ozone in the contact oxidation chamber is 1 hour. The residence time of the filter is 1 hour, and the COD removal rate of this treatment method is 90%. The average C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com