Catalytic ozonation treating apparatus and process for refractory organic wastewater

A technology of ozone catalytic oxidation and organic wastewater, applied in the direction of oxidized water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of low oxygen utilization rate, improve ozone utilization rate and ensure operation Safety, destructive power enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

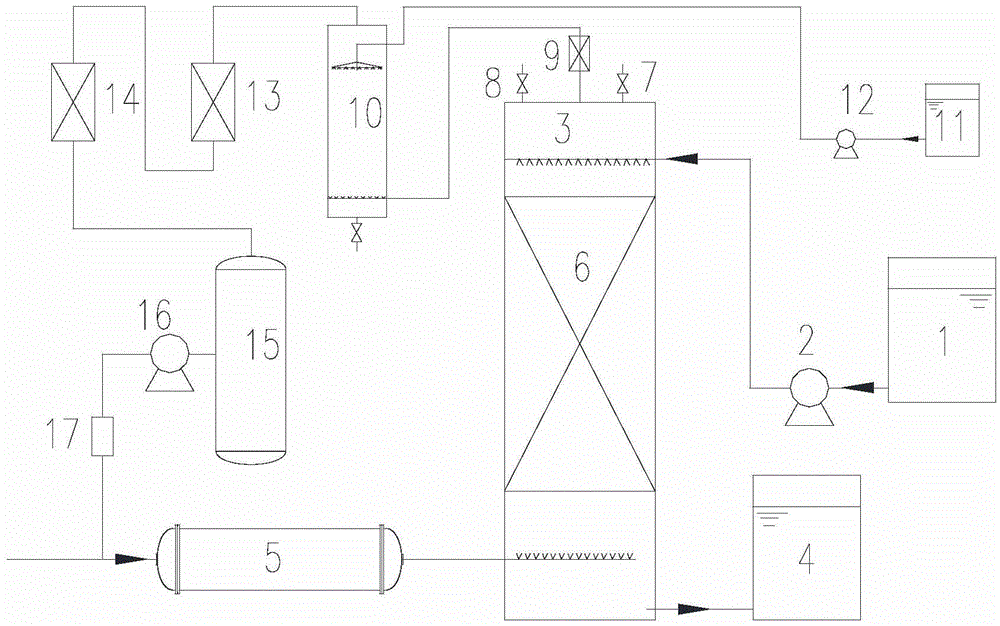

[0053] The device is used for advanced treatment of coal chemical wastewater.

[0054] After biochemical and coagulation treatment of coal chemical wastewater, the residual COD is mainly refractory organic pollutants, with a COD of 150-200mg / L and a chroma of 100-200 times. The waste water enters the water storage tank 1, enters the catalytic oxidation tower 3 from the top through the water inlet pump 2, and the catalytic oxidation tower 3 is filled with catalyst components 6. Oxygen content is that the gas of 90-100% produces the ozone concentration that is about 10% through ozone generator 5, adjusts the air intake to ensure that the ozone dosing amount is 150-400mg / L waste water, described refractory organic waste water and ozone generator The flow ratio of the generated ozone is 1:0.5, and the ozone enters the catalytic oxidation tower 3 from the bottom and contacts with the coal chemical wastewater in the catalytic oxidation tower 3 in cross-flow, and catalytic oxidation ...

specific Embodiment 2

[0057] The device is used for advanced treatment of printing and dyeing wastewater.

[0058] After printing and dyeing wastewater undergoes traditional primary and secondary treatment, the residual COD is mainly refractory organic pollutants with chromophoric groups, with a COD of 300-500 mg / L and a chromaticity of 200-400 times. The waste water enters the water storage tank 1, enters the catalytic oxidation tower 3 from the top through the water inlet pump 2, and the catalytic oxidation tower 3 is filled with catalyst components 6. Oxygen content is that the gas of 90-100% produces the ozone concentration that is about 10% through ozone generator 5, adjusts the air intake to ensure that the ozone dosing amount is 300-1000mg / L waste water, described refractory organic waste water and ozone generator The flow ratio of the generated ozone is 1:1.5. The ozone enters the catalytic oxidation tower 3 from the bottom and cross-flow contacts with the printing and dyeing wastewater in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com