Multi-station automatic welding equipment

An automatic welding, multi-station technology, applied in the field of workpiece welding, can solve the problem of not having an effective clamping mechanism for workpieces, not having, and not having odor, etc., to avoid physical discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

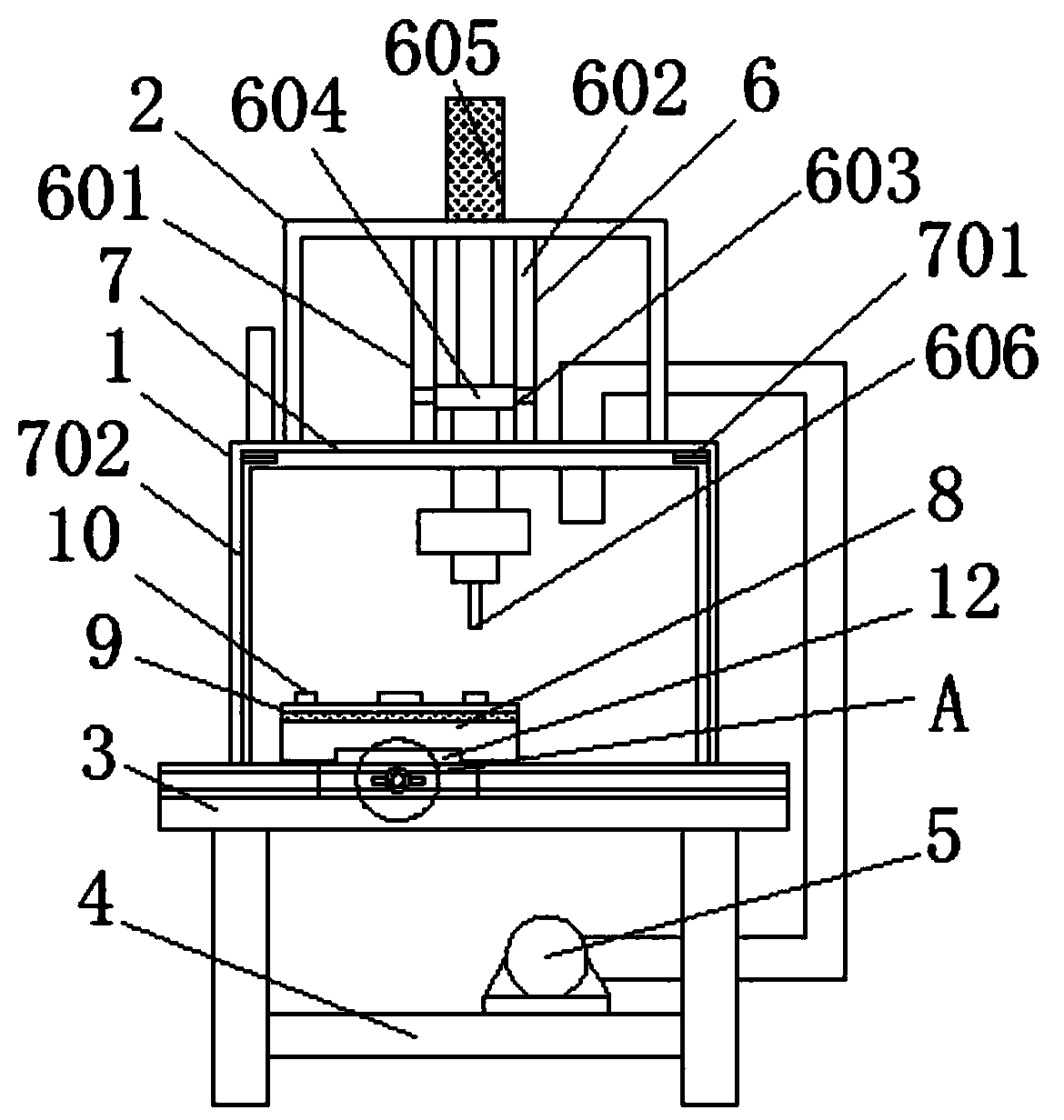

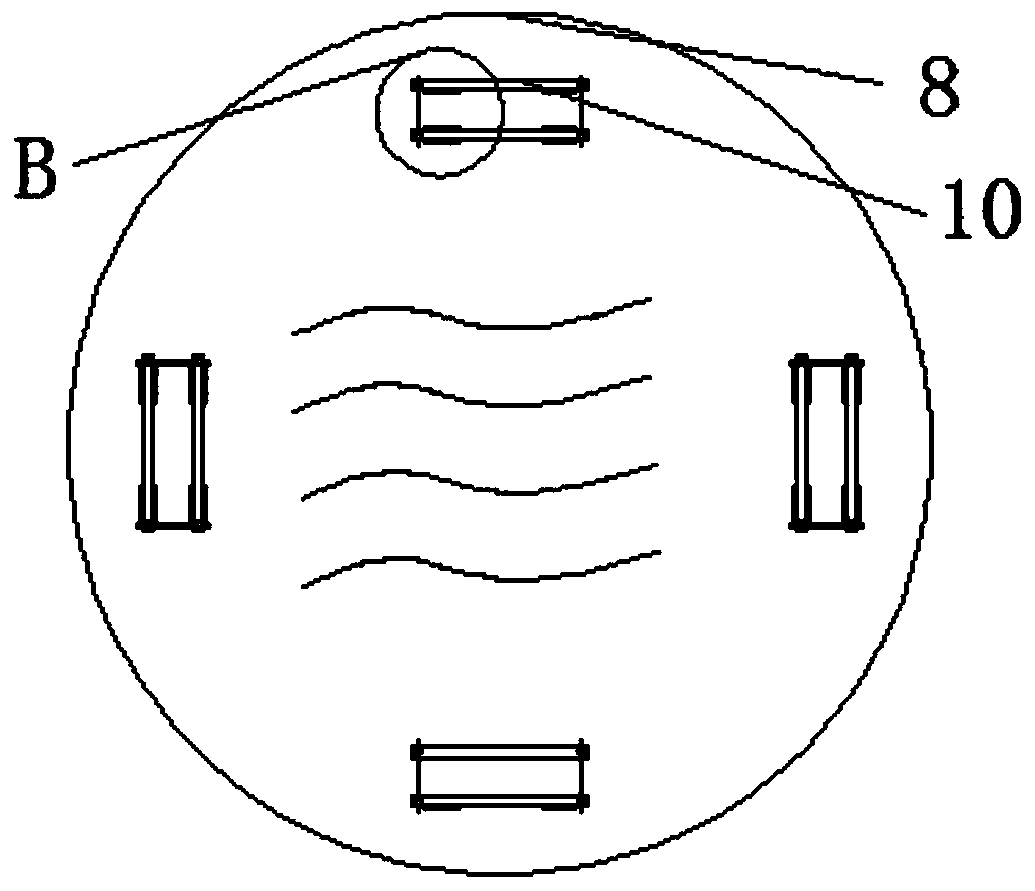

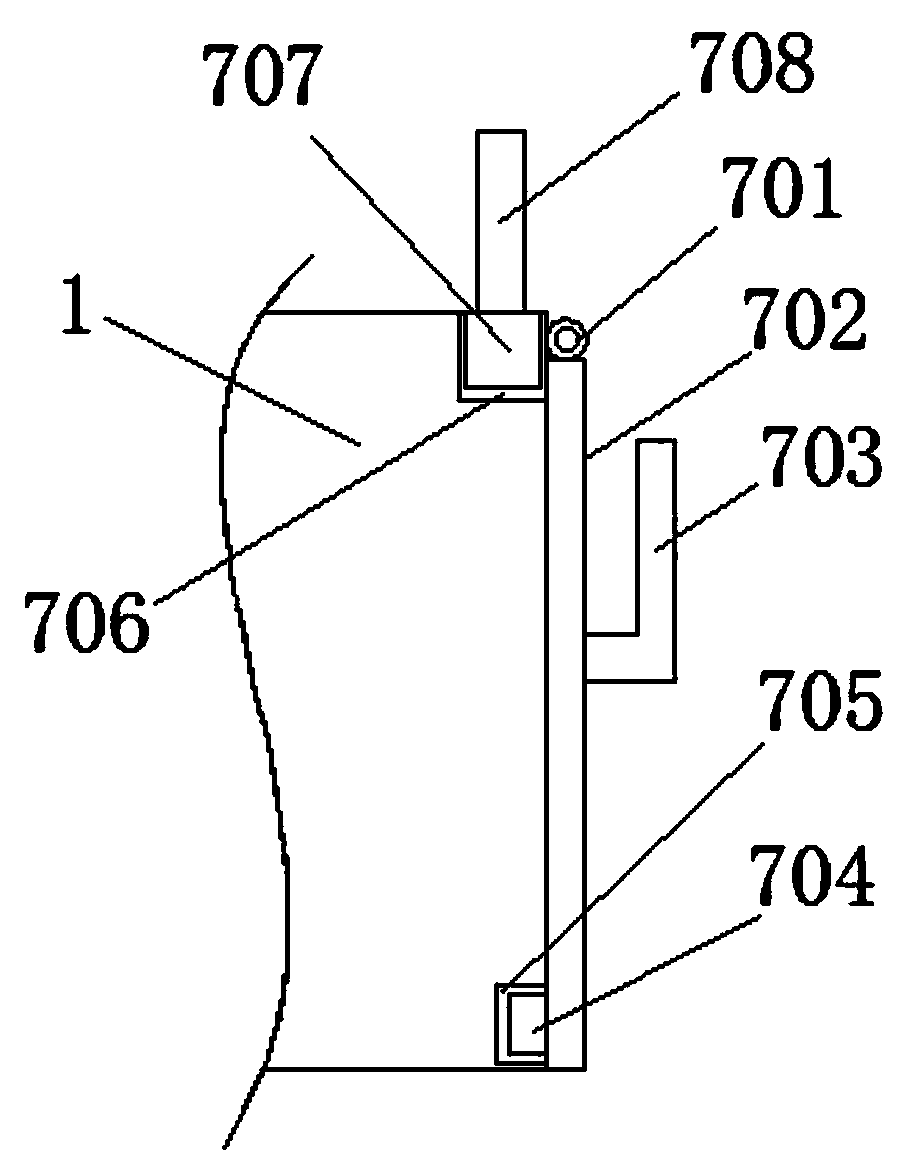

[0035] Embodiment 1: as figure 1 — Figure 5 , a multi-station automatic welding equipment, comprising: a frame 1, a support frame 2, a workbench 3, a load plate 4, a centrifugal fan 5, a lifting mechanism 6, a fixed outer rod 601, a first chute 602, and a first slider 603, connecting plate 604, electric telescopic rod 605, welding head 606, sealing mechanism 7, first hinge 701, sealing cover 702, L-shaped clamping plate 703, magnetic clamping plate 704, magnetic clamping slot 705, second chute 706 , the second slider 707, the movable clamping plate 708, the welding table 8, the ring baffle 9, the clamping mechanism 10, the second hinge 1001, the splint 1002, the fixed block 1003, the porous insert rod 1004, the thumb screw 1005, The adjustment mechanism 11, the third chute 1101, the third slider 1102, the transverse groove 1103, the push rod 1104, the thumb bolt 1105 and the rotating shaft 12, the top of the frame 1 is fixedly connected with the support frame 2, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com