Quenching treatment equipment and quenching treatment process for engine crankshaft

A technology for processing equipment and engines, applied to heat treatment equipment, quenching devices, heat treatment furnaces, etc., can solve problems such as difficult clamping operations, difficult uniform cooling, and large cross-sectional size of sampling parts, so as to improve work efficiency, stable and uniform cooling, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

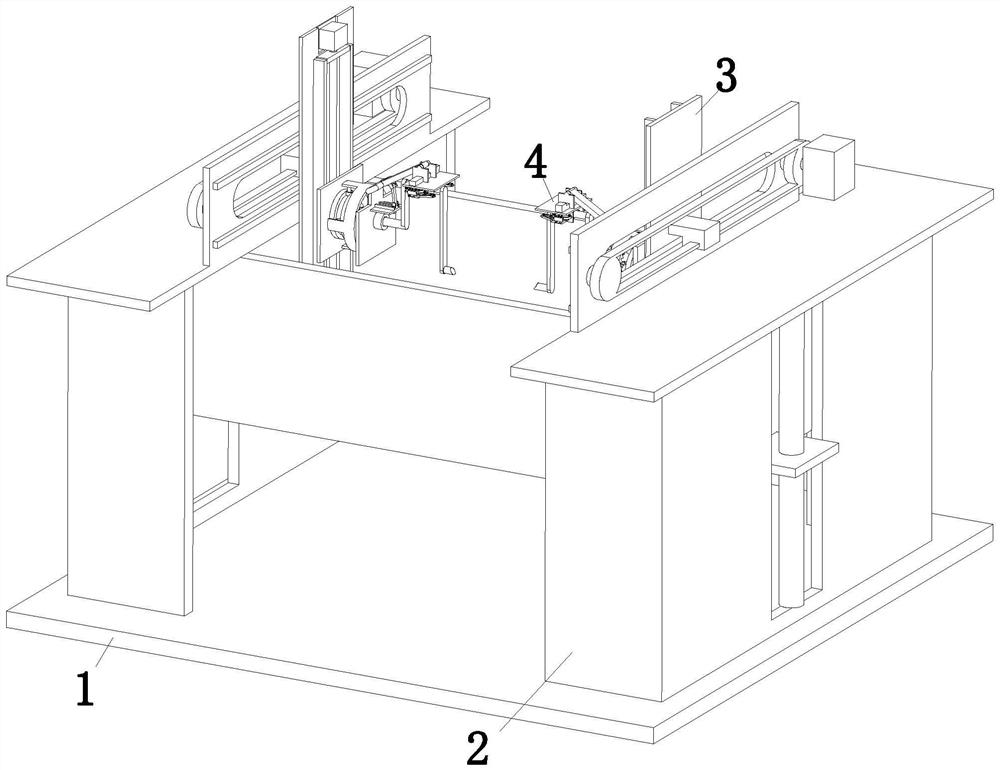

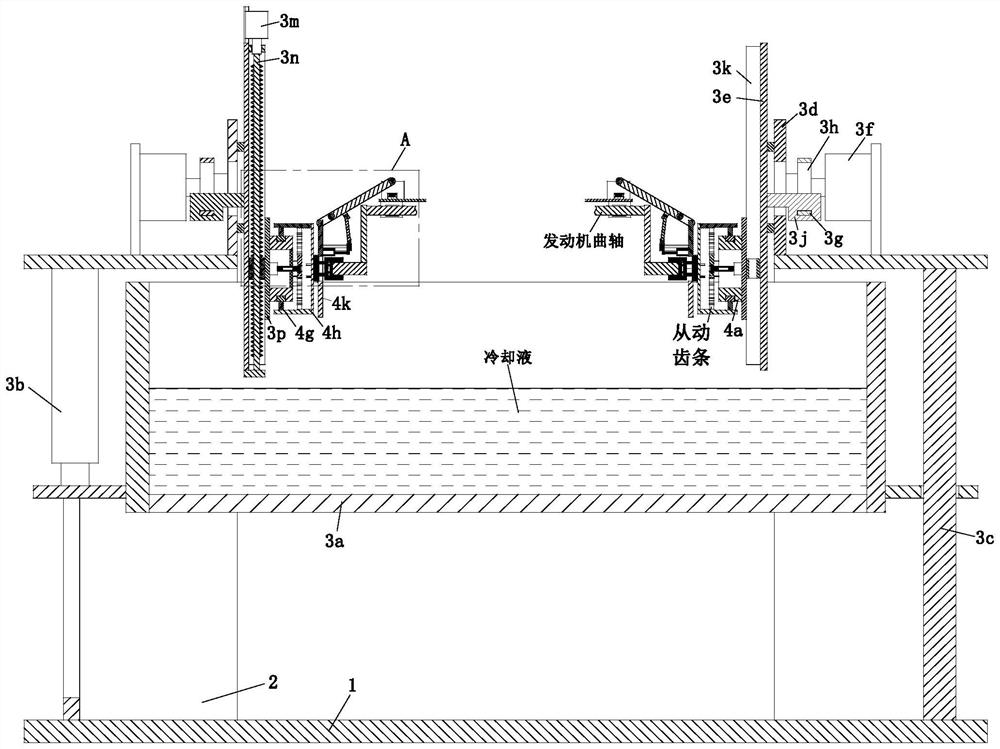

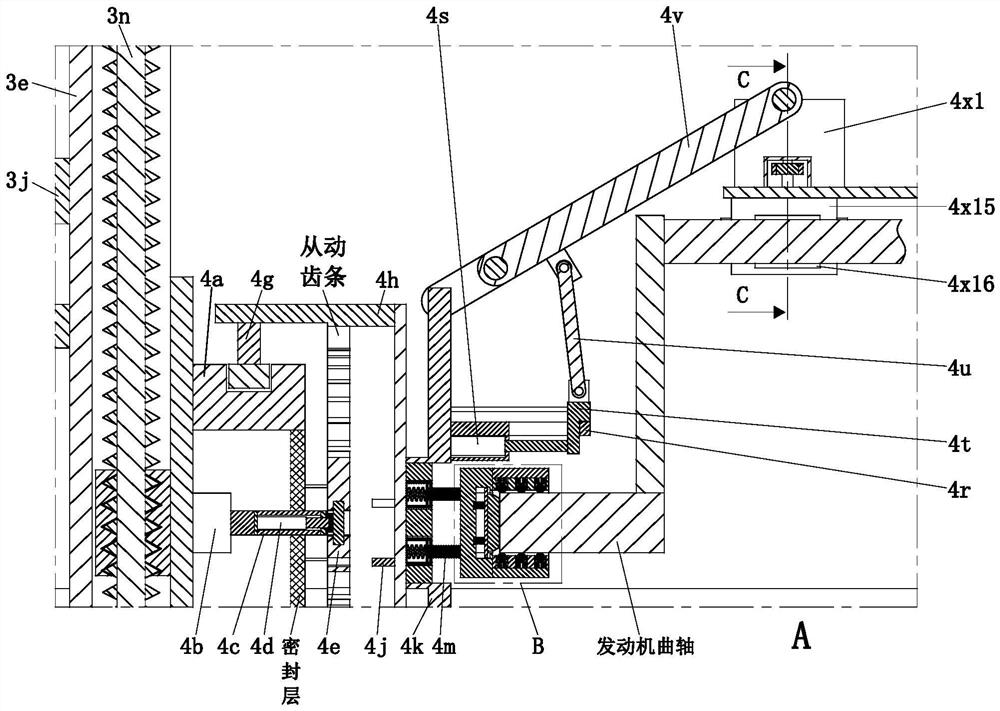

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0026] An engine crankshaft quenching treatment equipment, comprising a mounting base plate 1, a support frame 2, a cooling mechanism 3 and a clamping and rotating mechanism 4, the upper end of the mounting base plate 1 is symmetrically installed with a support frame 2, and the support frame 2 is symmetrically installed by sliding fit There is a cooling mechanism 3 on which a clamping and rotating mechanism 4 is mounted symmetrically through rotational fit, and the clamping and rotating mechanism 4 is located between the support frames 2 .

[0027]The cooling mechanism 3 includes a cooling box 3a, a lifting electric push rod 3b, a lifting slide bar 3c, a shifting bottom plate 3d, a shifting slide plate 3e, a shifting motor 3f, a synchronous belt 3g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com