Symmetrical-gripping-jaw fixture capable of rotating 180 degrees

A clamping jaw and fixture technology, which is applied in the field of fixtures, can solve the problems of inability to install fixtures, small application scope, and low firmness of workpieces, and achieves the effect of reducing labor intensity and improving clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

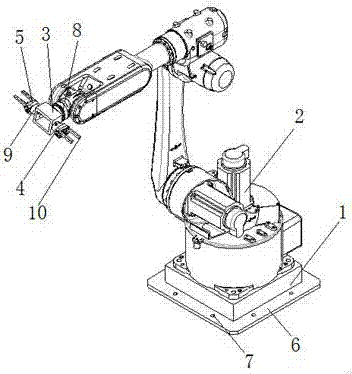

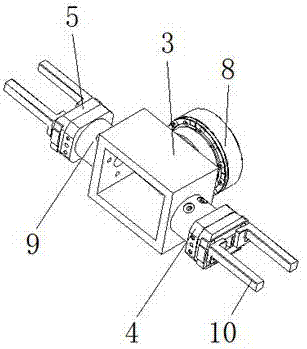

[0018] as attached figure 1 and 2 As shown, a symmetrical jaw fixture that can rotate by 180° includes a robot base 1, a robot 2, a flange mounting seat 3, a mounting plate 4 and a jaw 5, and is characterized in that: the robot 2 is set on the robot base 1, the flange mounting seat 3 is set on the robot 2 through the connecting shaft 8, and fixed blocks 9 are arranged on opposite sides of the flange mounting seat 3, and the mounting plate 4 is set on the fixed block 9 , the clamping jaw 5 is arranged on the mounting plate 4 , and a clamping rod 10 is arranged on the clamping jaw 5 .

[0019] Preferably, the robot base 1 is provided with a connection plate 6, and a connection hole 7 is provided on the connection plate 6, through the connection plate 6 and the connection hole 7, the stability of the robot 2 in the workpiece clamping and installation process can be improved performance, thereby improving the stability of workpiece clamping and installation.

[0020] Preferably...

Embodiment 2

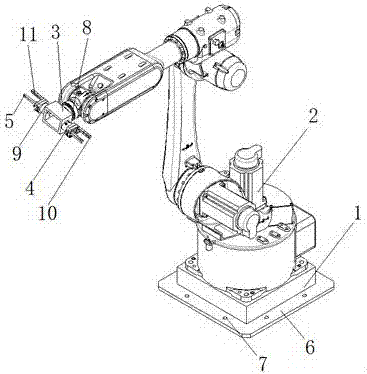

[0024] as attached image 3 and 4 As shown, a symmetrical jaw fixture that can rotate by 180° includes a robot base 1, a robot 2, a flange mounting seat 3, a mounting plate 4 and a jaw 5, and is characterized in that: the robot 2 is set on the robot base 1, the flange mounting seat 3 is set on the robot 2 through the connecting shaft 8, and fixed blocks 9 are arranged on opposite sides of the flange mounting seat 3, and the mounting plate 4 is set on the fixed block 9 , the clamping jaw 5 is arranged on the mounting plate 4 , and a clamping rod 10 is arranged on the clamping jaw 5 .

[0025] Preferably, the robot base 1 is provided with a connection plate 6, and a connection hole 7 is provided on the connection plate 6, through the connection plate 6 and the connection hole 7, the stability of the robot 2 in the workpiece clamping and installation process can be improved performance, thereby improving the stability of workpiece clamping and installation.

[0026] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com