A mailbox device

A mailbox and hollow technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of low work efficiency, low efficiency, inconvenient use, etc., and achieve the effect of improving the stability of forward and backward movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

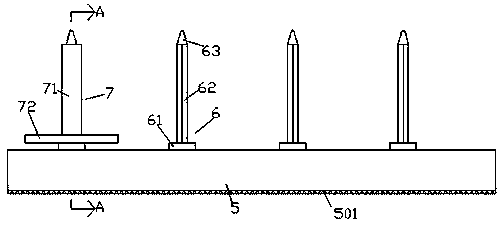

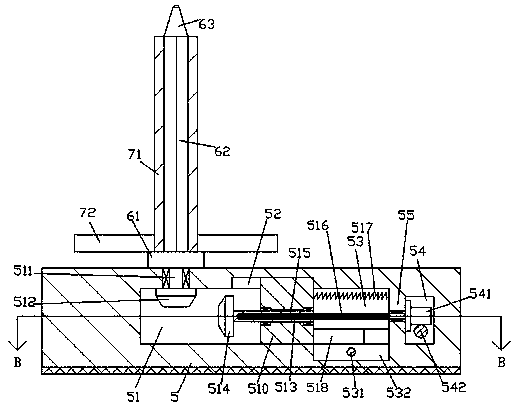

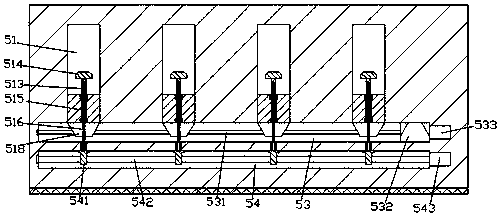

[0021] Such as Figure 1-Figure 6 As shown, a letter box device of the present invention includes a base 5 and surrounding devices 6 distributed on the top end surface of the base 5 at the same distance. A flexible pad 501 is fixedly arranged on the bottom of the base 5, and each surrounding The base 5 below the device 6 is provided with a driving cavity 51 extending to the front side, and the front side of the driving cavity 51 is connected with a first hollow cavity 53 extending left and right, and the first cavity The base 5 on the front side of the cavity 53 is provided with a second cavity 54, and a partition plate 55 is provided between the first cavity 53 and the second cavity 54, and each drive-in cavity The front side of the inner top of 51 is provided with a guide groove 52, and each guide groove 52 is provided with a first sliding joint frame 510 extended downwards, and the extended section of the bottom of the first sliding joint frame 510 penetrates the The drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com