Novel power cable equipment

A technology for power cables and equipment, applied in the field of new power cable equipment, can solve the problems of inconvenient use, low work efficiency, waste of man-hours, etc., and achieve the effects of improving work efficiency, improving efficiency, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

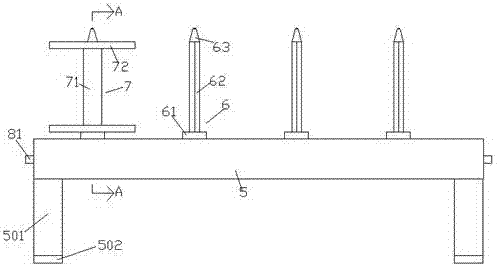

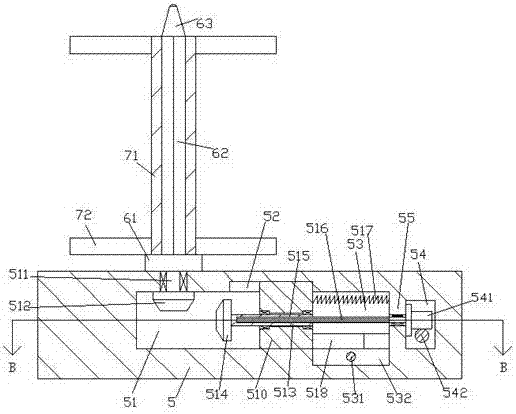

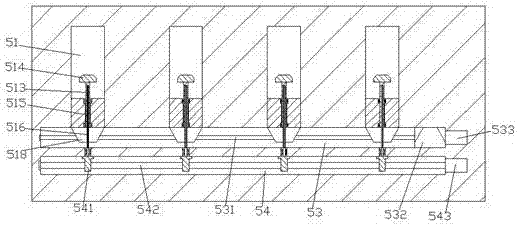

[0022] Such as Figure 1-Figure 6 As shown, a new type of power cable equipment of the present invention includes a frame 5 and winding members 6 evenly distributed on the top end surface of the frame 5, a column 501 is arranged at the bottom of the frame 5, and a column 501 is installed at the bottom of the column 5 There is an anti-slip pad 502, and the frame 5 below each of the winding members 6 is provided with a drive cavity 51 extending to the front side, and the rear side of the drive cavity 51 communicates with a first space extending left and right. A cavity 53, a second cavity 54 is provided in the frame 5 on the front side of the first cavity 53, a spacer 55 is provided between the first cavity 53 and the second cavity 54, Each of the first cavities 53 is provided with a guide groove 52 on the inner top of the front side, each of the guide grooves 52 is provided with a first sliding frame 510 extending downward, and the bottom of the first sliding frame 510 is The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com