Vacuum roll kneading machine for food processing

A vacuum tumbler and food processing technology, which is applied in the fields of meat processing, application, food science, etc. It can solve the problems of low meat tumbling efficiency, small impact and beating effects, etc., so as to improve the tumbling efficiency and enhance the tumbling The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

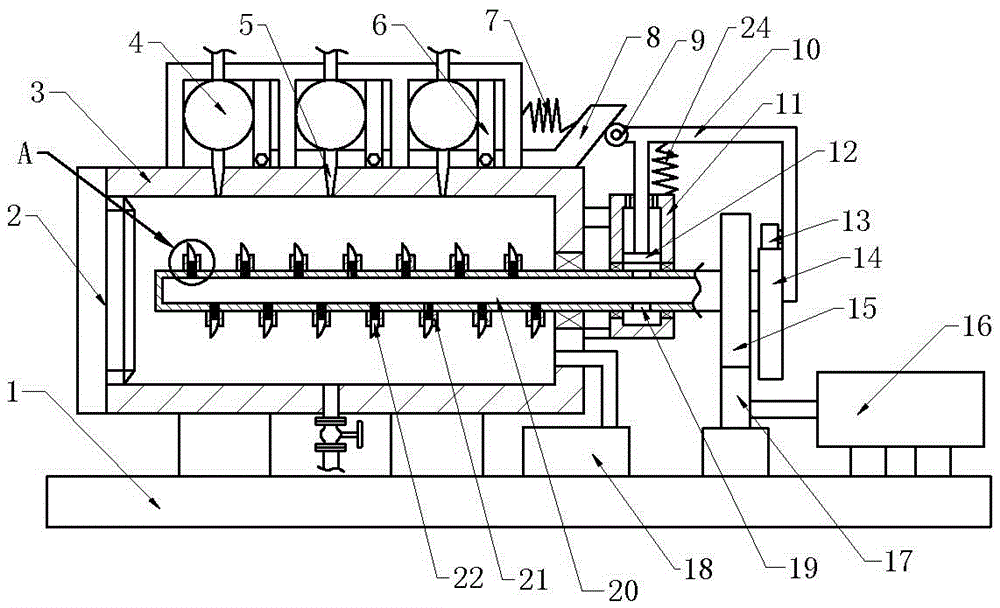

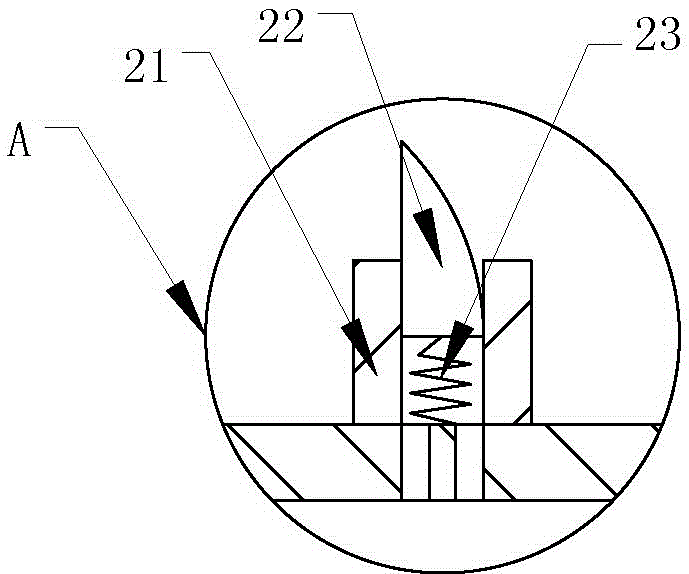

[0020] Example: such as figure 1 with figure 2 As shown, the vacuum tumbler for food processing includes a frame 1, a vacuum pump 18 and a tumbler 3, the tumbler 3 is fixed on the frame 1 by bolts, and the left side of the tumbler 3 is threadedly connected with a cover 2, The vacuum pump 18 is in communication with the tumbler 3, and the inner part of the tumbler 3 is connected with a rotating shaft 20. The rotating shaft 20 is a hollow structure. The rotating shaft 20 in the tumbler 3 is integrally formed with two groups of axial etc. Sliding cylinders 21 arranged at intervals, two sets of sliding cylinders 21 are arranged alternately, and the rotating shaft 20 is provided with a number of axially equidistantly arranged through holes for matching sliding cylinders 21. There is a rolling knife 22, a first spring 23 is connected between the rolling knife 22 and the wall of the rotating shaft 20 in the sliding cylinder 21, the rotating shaft 20 outside the rolling barrel 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com