Meat dressing/boning method and system

a meat dressing and bone technology, applied in meat processing plants, butchering, poultry processing, etc., can solve the problems of increased contact area, increased operation time, complicated work, etc., and achieve the effect of contaminating the meat block with bones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

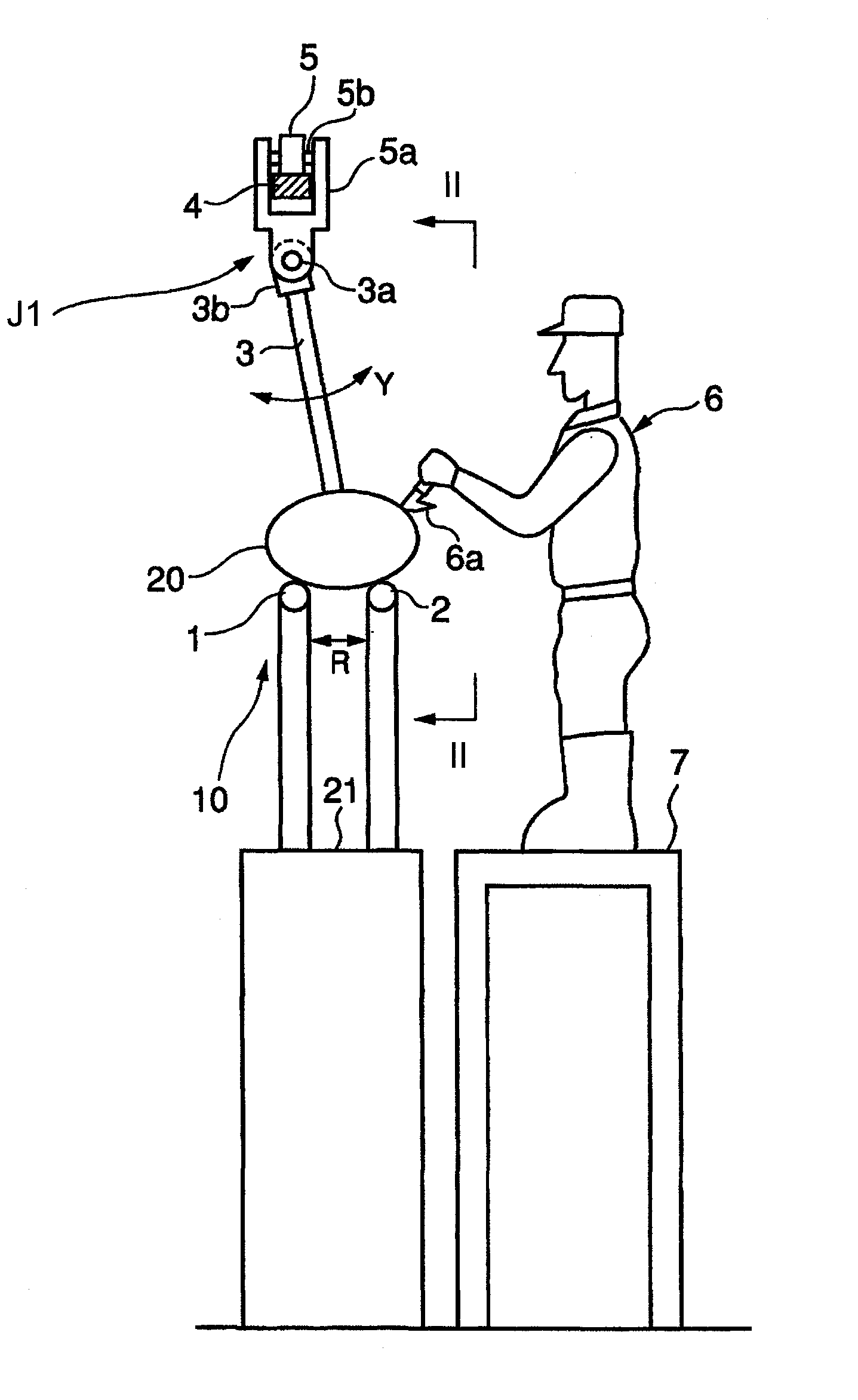

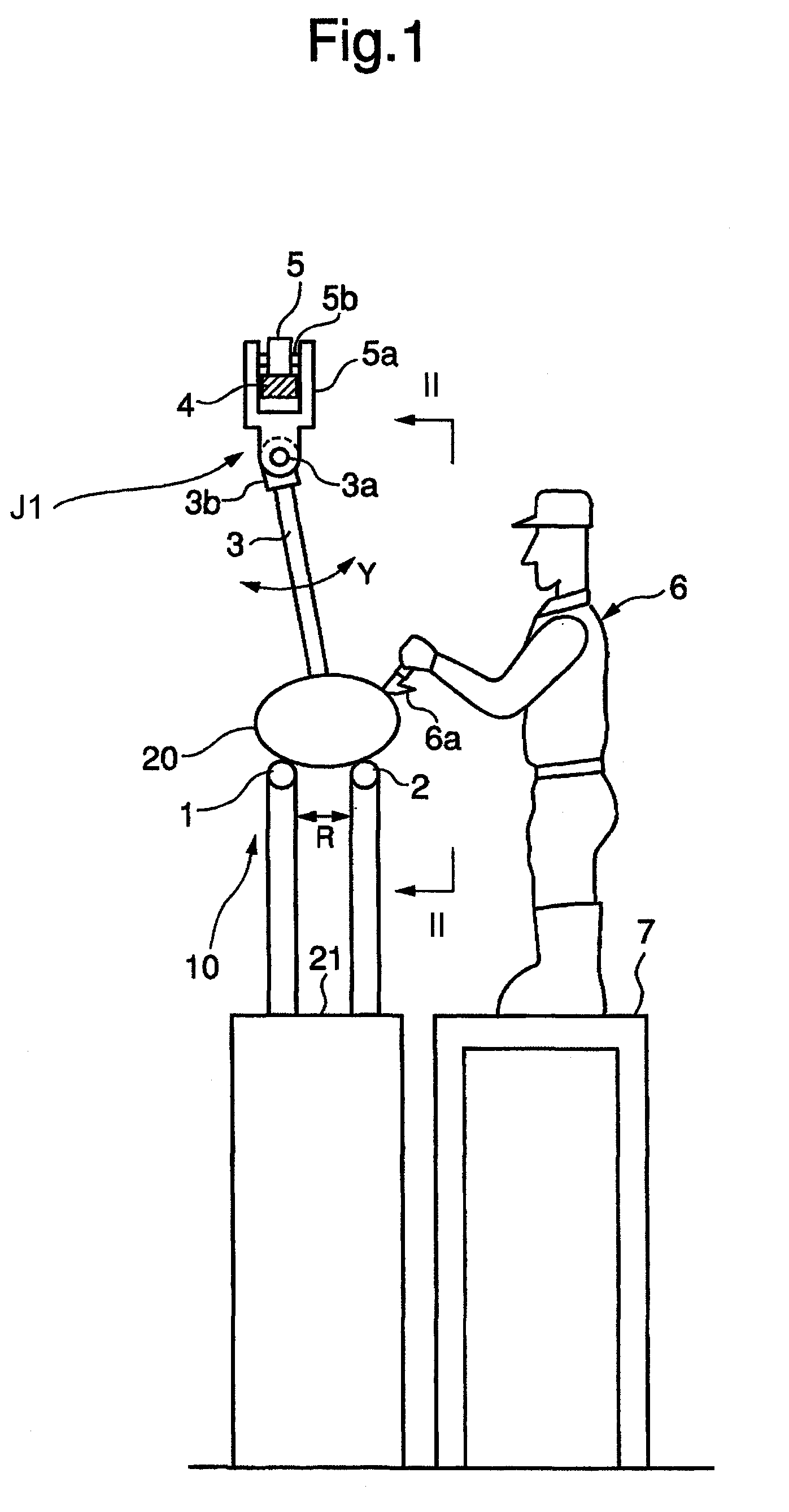

first embodiment

[0060] The composition of the hanging mechanism of the meat block 20 shown in FIG. 4 is similar to that of FIG. 1.

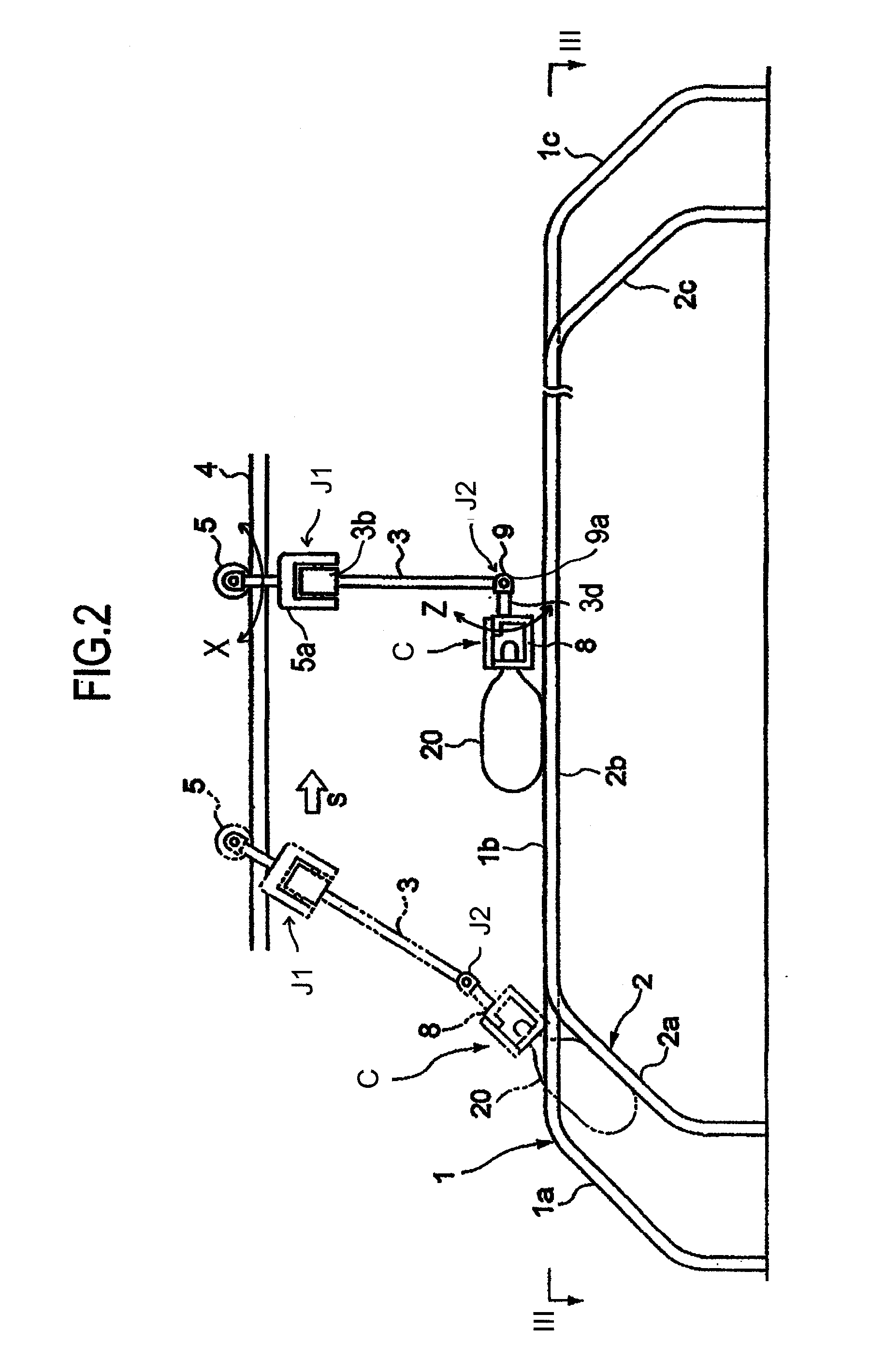

[0061]FIGS. 6A and 6B show another embodiment of the clamp mechanism C in detail. The clamp mechanism C of FIG. 6A is similar to that of FIG. 5A except that the connecting bar 3d of FIG. 5A is connected rotatably to the clamper 8. Referring to FIG. 6B, an inserting portion 3e of the connecting bar 3d is loosely fitted to a hole 8c in the clamper 8 so that the clamper 8 can be rotated around the center axis 3g of the connecting bar 3d as shown by arrows N. A stopper nut 34 is screwed to the threaded end part of the connecting bar 3d to prevent the connecting bar 3d from moving along the axial direction thereof.

second embodiment

[0062] the meat block 20 held by the clamp mechanism C is hung from the rail 4 by way of the roller 5, roller support 5a, first joint J1, supporting bar 3, second joint J2, and connecting bar 3d, can be swung in directions of accessing / departing to or from the worker 6 (the direction of arrows Y in FIG. 4), so that the distance from the worker to the meat block 20 can be changed by swinging the meat block guide 30 in the direction of accessing / departing to or from the worker 6 as indicated by arrows W by actuating the hydraulic cylinder 24.

[0063] Therefore, according to the second embodiment, as the meat block guide 30 is supported pivotably around the shaft 26 by means of the links 41, the meat block 20 can be swung by virtue of the first articulate member J1 by actuating the hydraulic cylinder 24 to push or pull the meat block guide 30 in directions W in FIG. 4 so as to swing the meat block guide 30. Accordingly, the dissection and boning operation can be carried out while changi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com