Mehtod for processing the color and lustre of fish meat

A processing method and technology of fish meat, applied in the direction of preserving meat/fish through radiation/electrical treatment, processing fish, cutting fish into parts, etc., can solve the problems of damaging appearance, human health damage, covering up the natural color of fish meat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

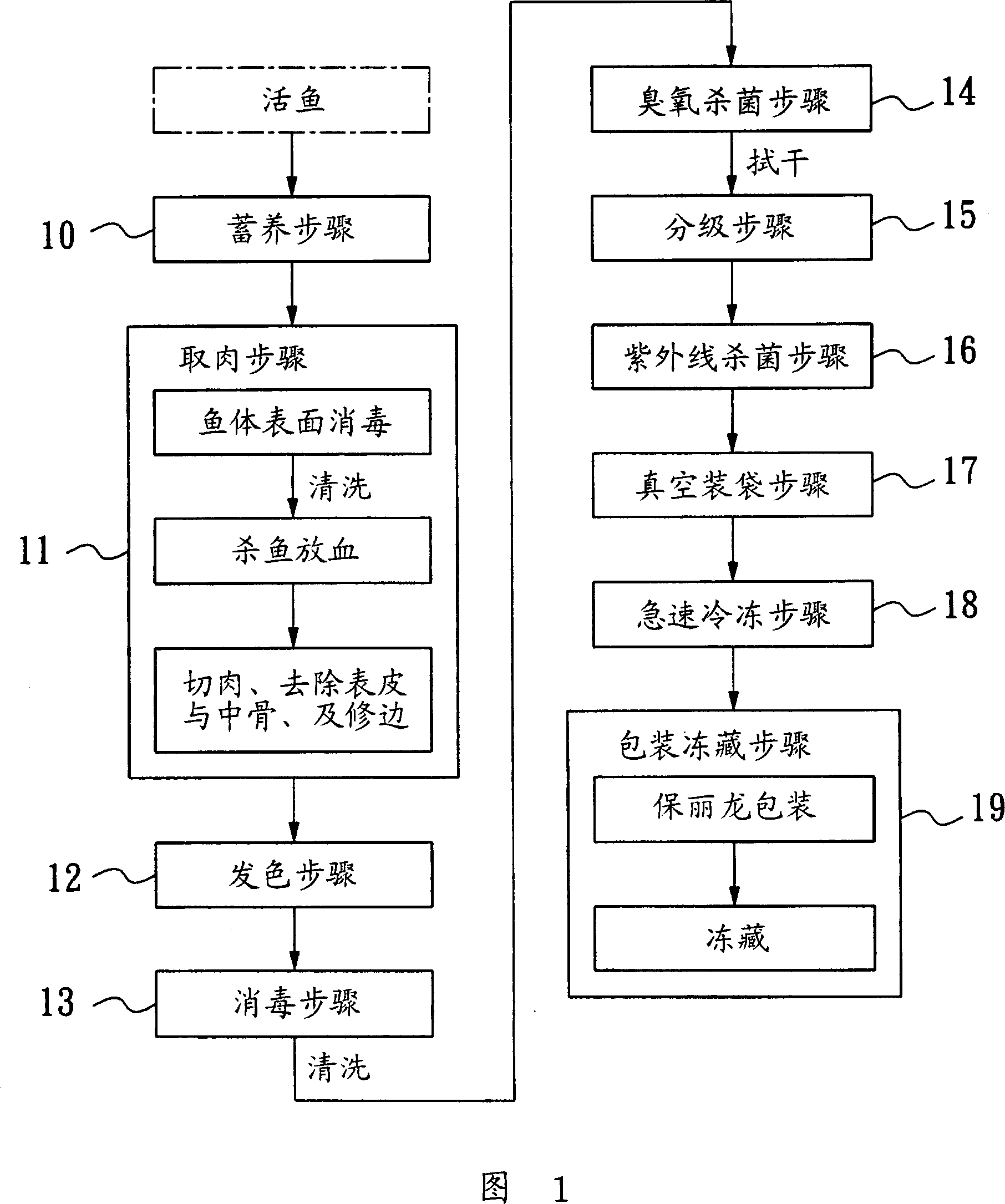

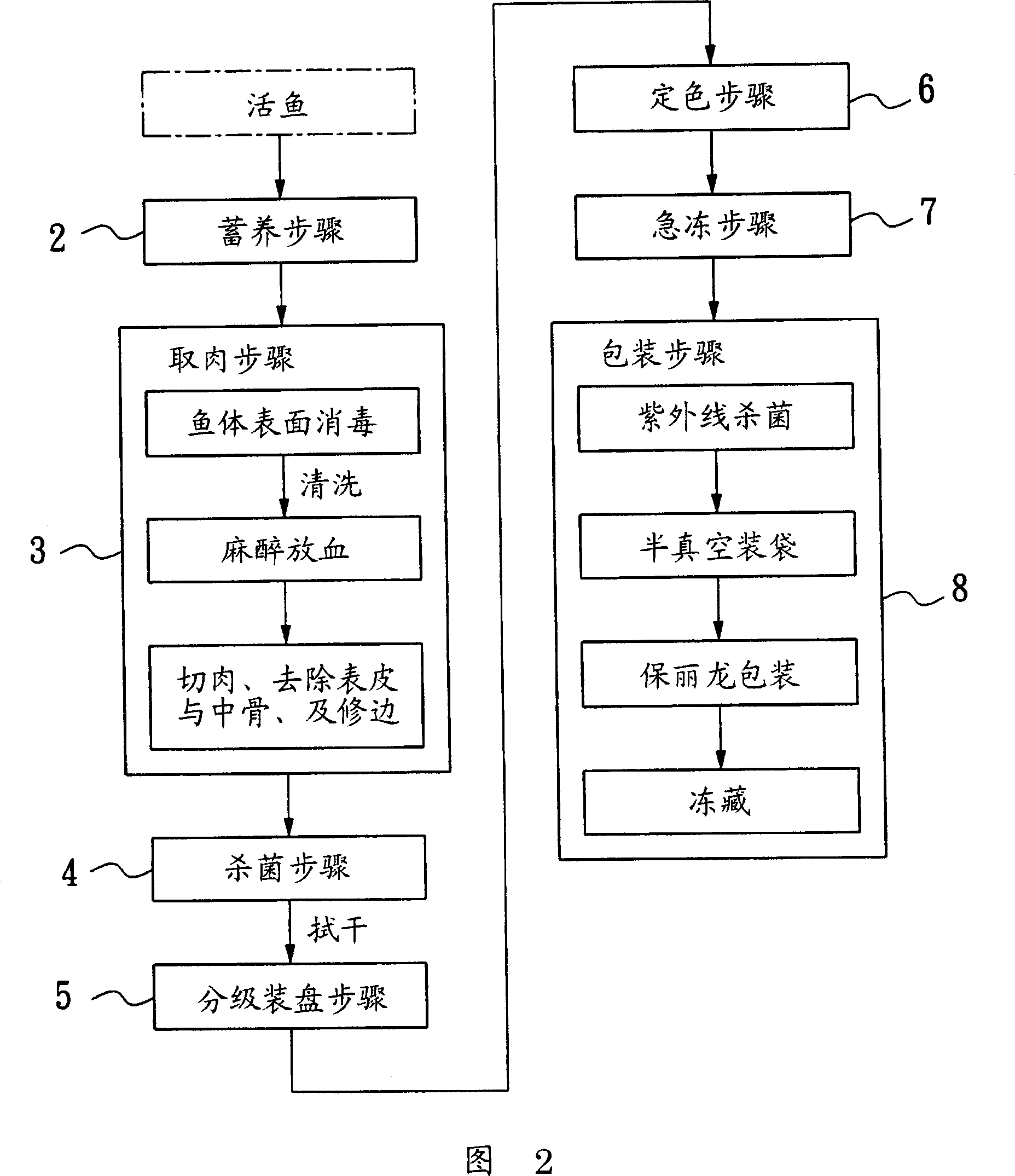

[0026] The fish meat color treatment method of the present invention will be described in detail below through preferred embodiments and accompanying drawings.

[0027] As shown in Figure 2, the preferred embodiment of the fish meat color treatment method of the present invention includes step 2 of storage, step 3 of taking meat, step 4 of sterilization, step 5 of grading and packing, step 6 of fixing color, step 7 of quick freezing, And packaging step 8.

[0028] The storage step 2 is to fish the live fish to be treated into another fish pond with clean water quality and store it for at least 12 hours, allowing the live fish to discharge most of the filth in the body.

[0029] The meat-taking step 3 is to immerse the live fish after draining the filth into sodium hypochlorite or chlorine dioxide solution to disinfect the surface of the fish. The aforementioned sodium hypochlorite is commonly known as bleach, which can destroy the protein of microorganisms, thereby effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com