Automatic arranging device for mixed packages

An automatic sorting and wrapping technology, applied in the field of conveyors, can solve the problems of parcel bursting, low production efficiency, and excessive labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

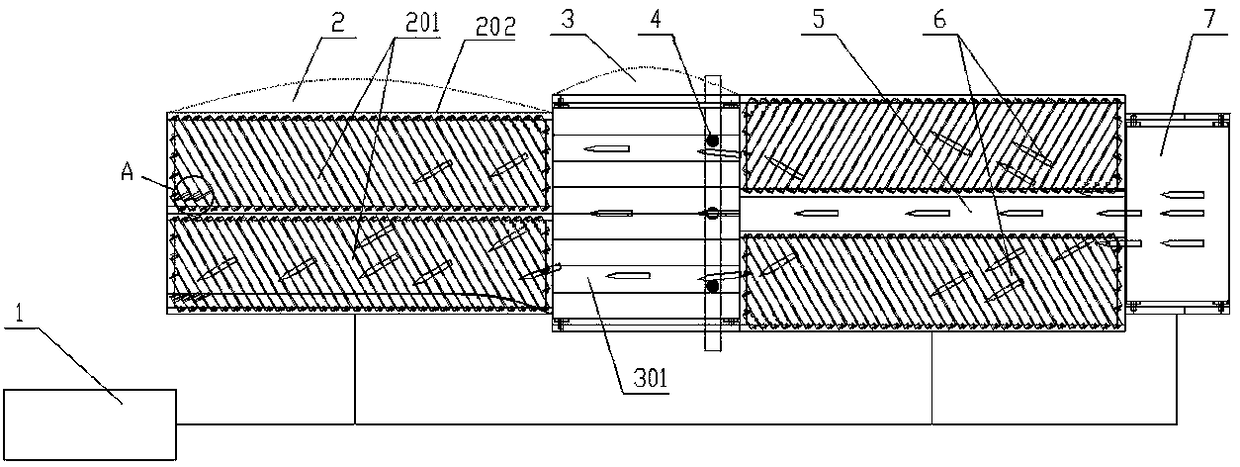

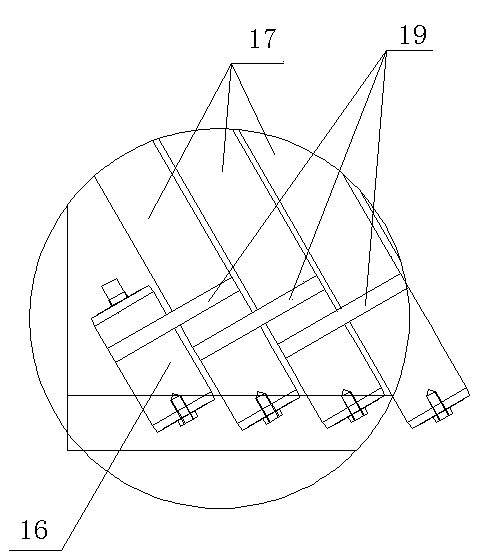

[0013] Such as figure 1 As shown, the package automatic arrangement device of the present invention includes a feed conveyor 7 and a controller 1, and after the feed conveyor 7, a differential center conveyor 5, a differential narrow belt conveyor 3 and sideways inclined roller conveying are arranged in sequence. Machine 2. Both sides of the differential center conveyor 3 are provided with diverting oblique roller conveyors 6 . The outer ends of the conveying rollers on the diverging skewed roller conveyor 6 are all inclined to the rear of the moving direction, the inclination angles of the conveying rollers on the two diverging inclined roller conveyors 6 are equal, and the speed of the differential center conveyor 5 is higher than that of the two. The speed of the side diverting inclined roller conveyor 6 is 10% higher. The differential speed narrow-belt conveyor 3 is composed of eight narrow-belt conveying units 301 with different speeds combined laterally. Wherein: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com