Method for alternating-current voltage withstand testing of 220 kV and 330 kV insulated tools and instruments

A technology of insulating tools and test methods, which is applied to instruments, measuring devices, measuring electricity and other directions to achieve the effects of good electrical performance, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

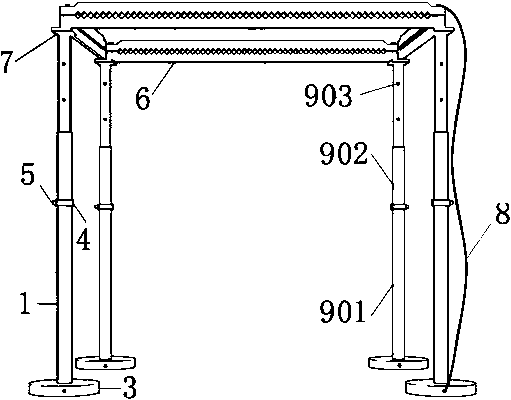

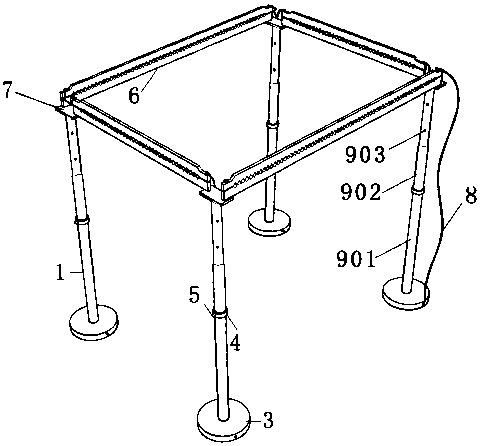

[0040] Examples of devices such as figure 1 and figure 2 Shown: a 220kV and 330kV insulating tool AC withstand voltage test device, characterized in that: the device includes a liftable device, two sets of splint electrodes 6 and a set of grounding device 8; the liftable device includes four liftable brackets 1 , four liftable supports 1 are arranged on the ground, and arranged in groups of 2×2 horizontally and vertically; two sets of splint electrodes 6 are respectively installed on the top of the front row and rear row liftable support 1; the liftable support 1 includes a base 3 1. A height-adjustable insulating pole 9 installed on the base 3, a supporting plate 7 is installed on the upper end of the height-adjustable insulating pole 9; one end of the grounding device 8 is connected with the supporting plate 7, and the other end is connected with the lifting support where the supporting plate 7 is located 1 to the chassis 3 connected.

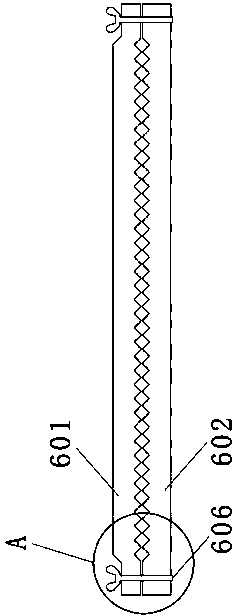

[0041] see image 3 and Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com