Patents

Literature

38results about How to "Increase placement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

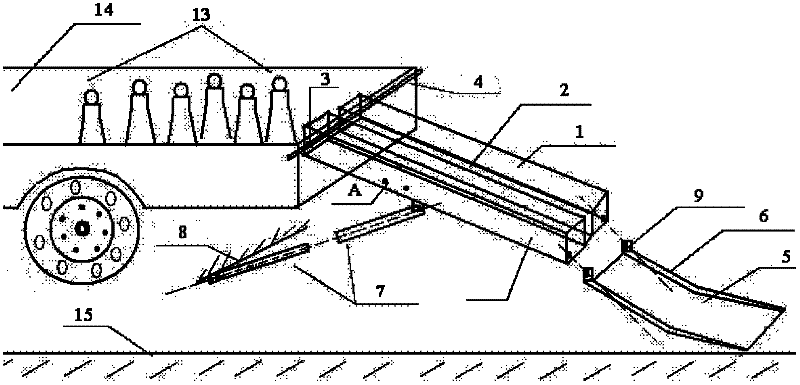

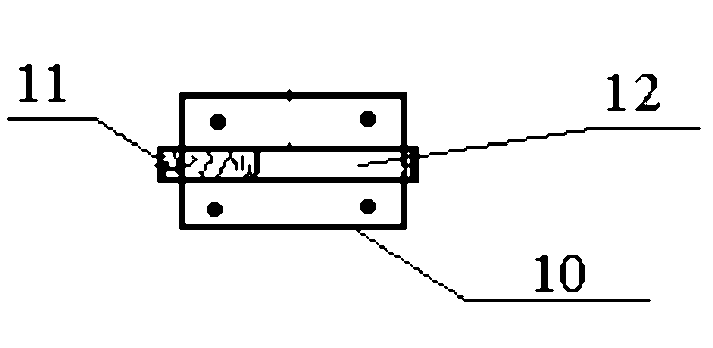

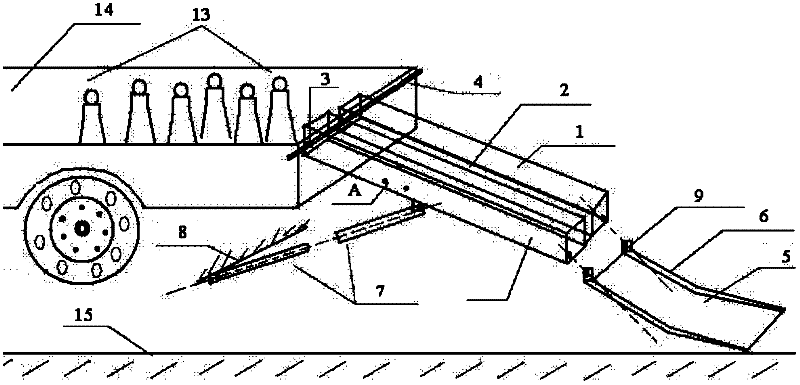

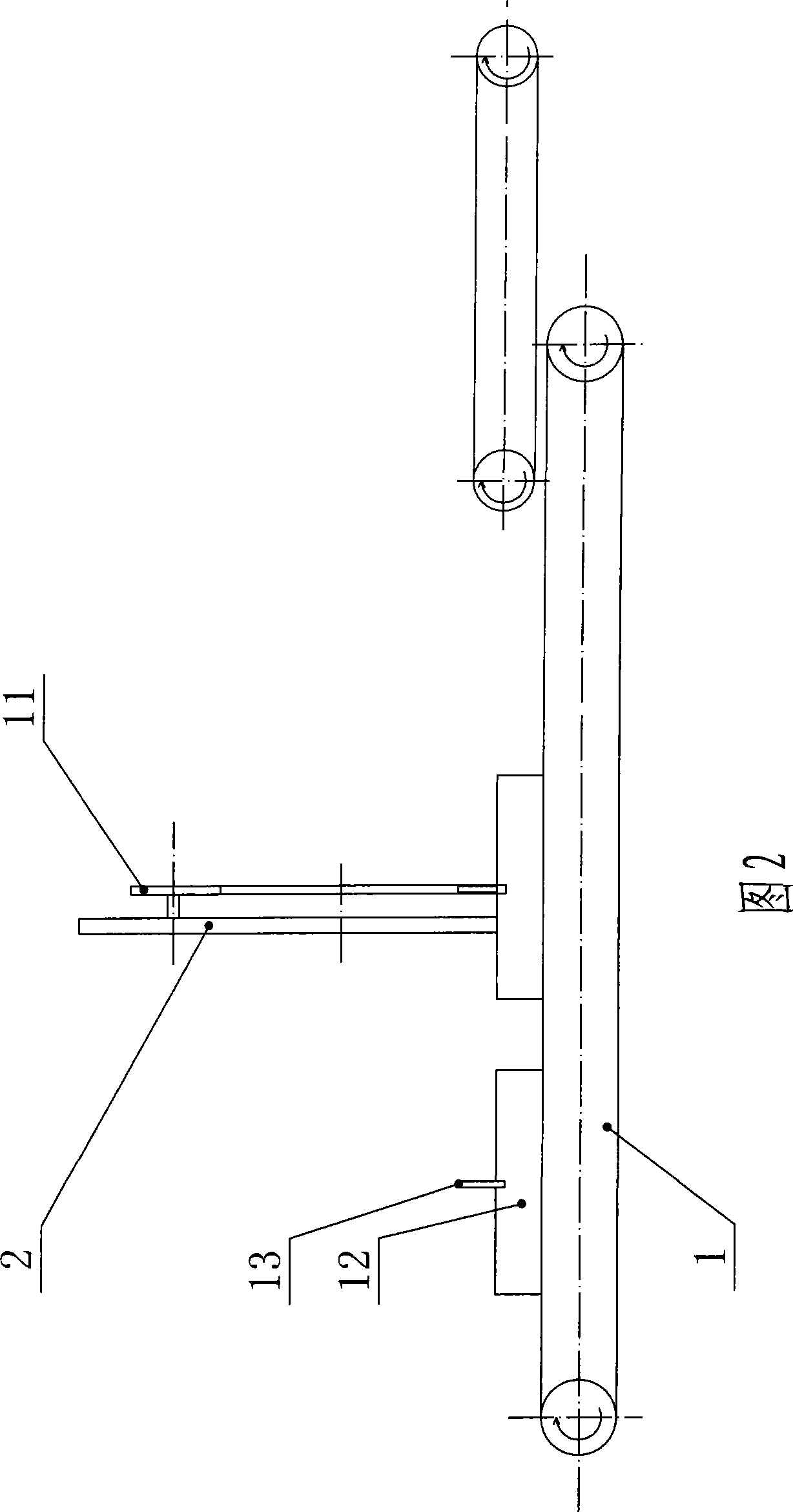

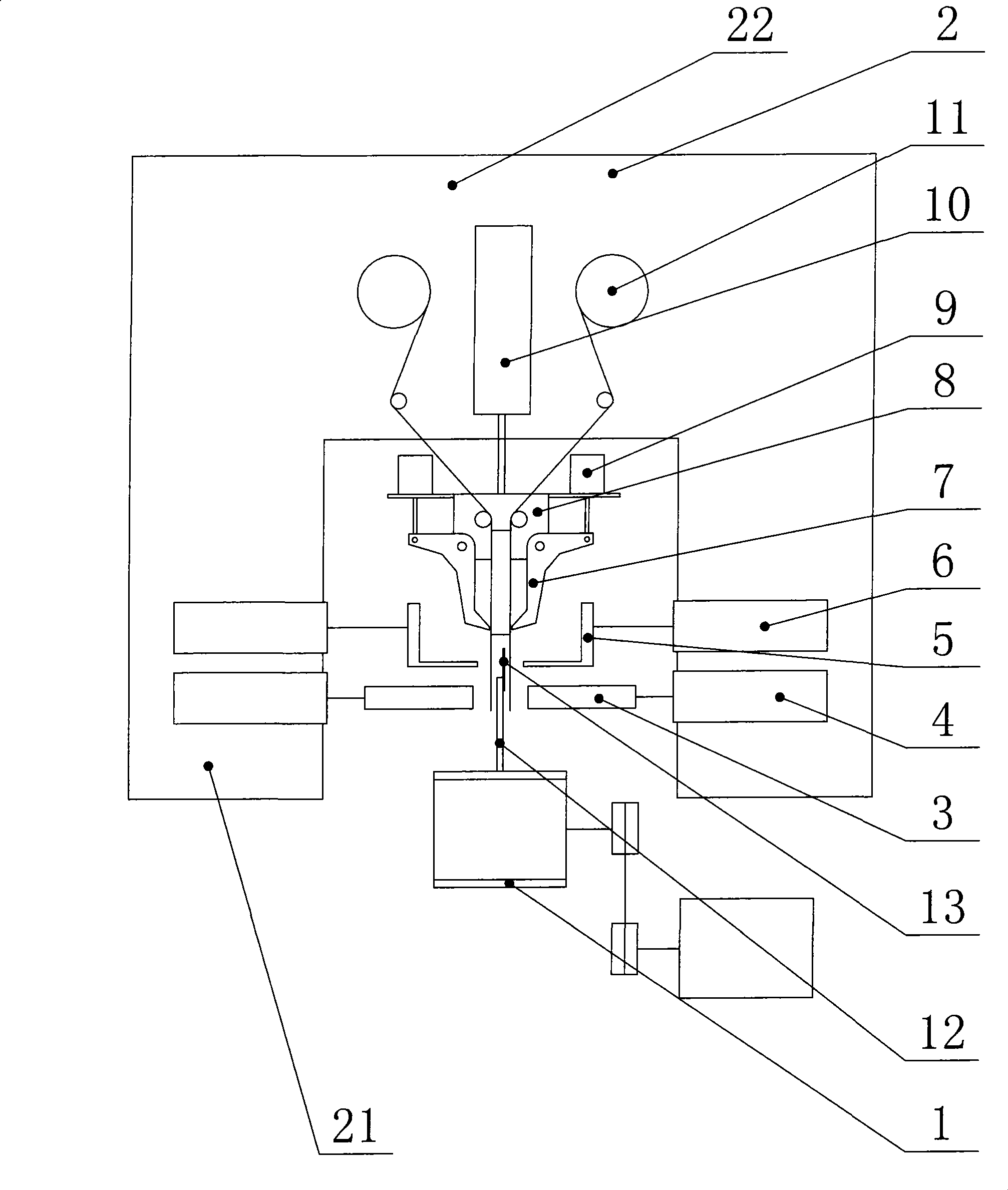

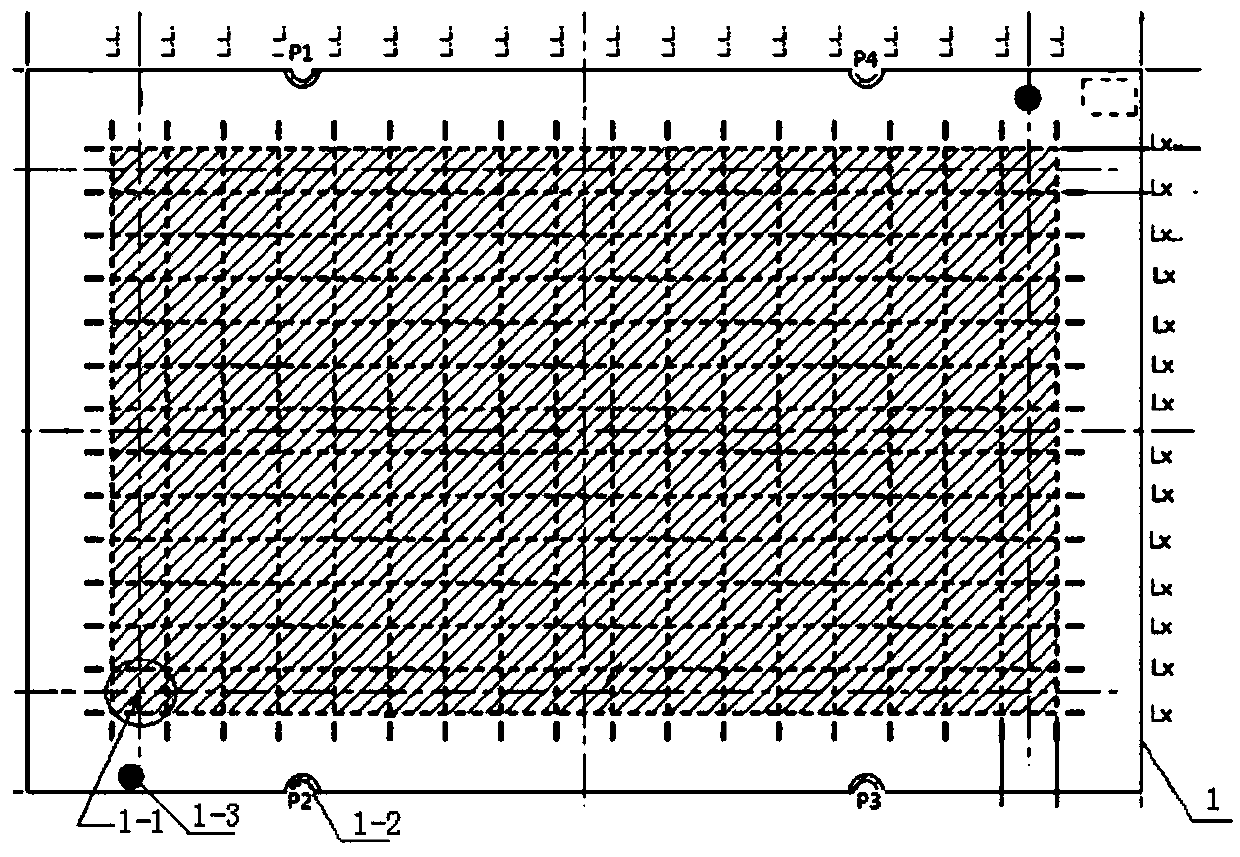

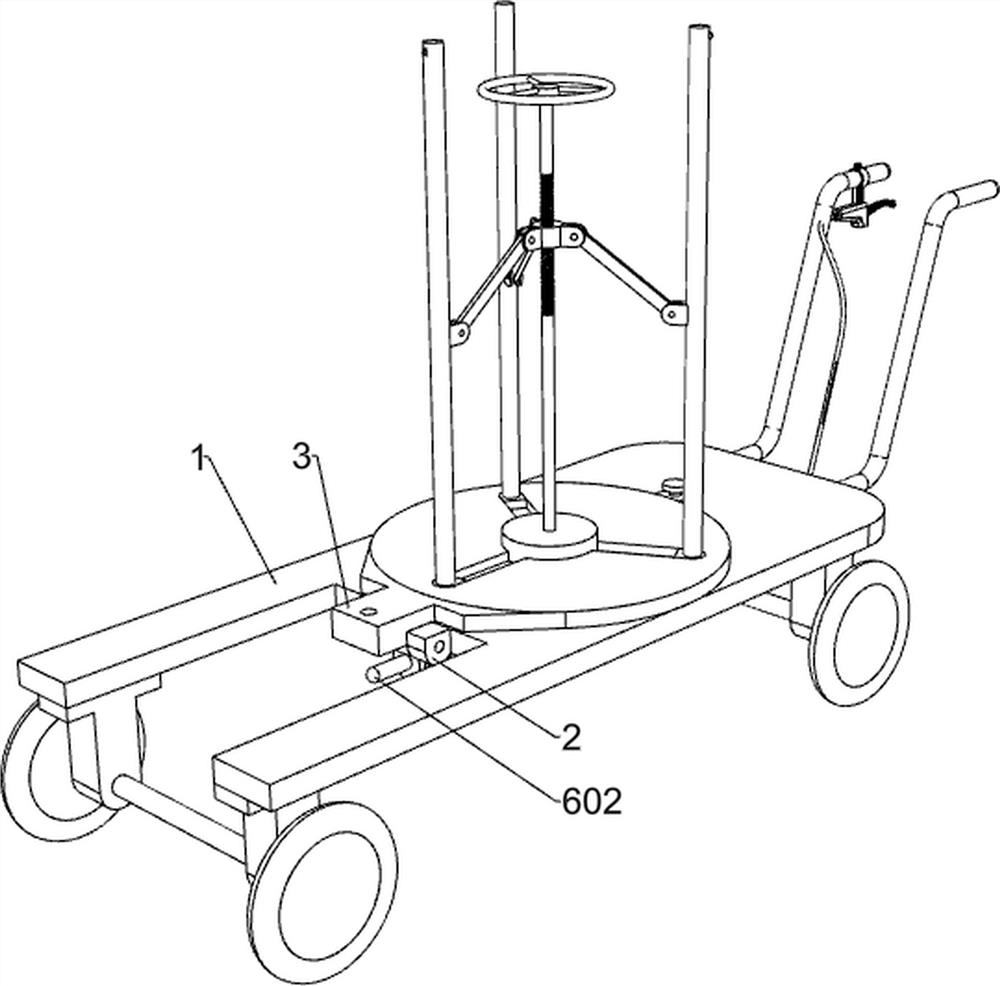

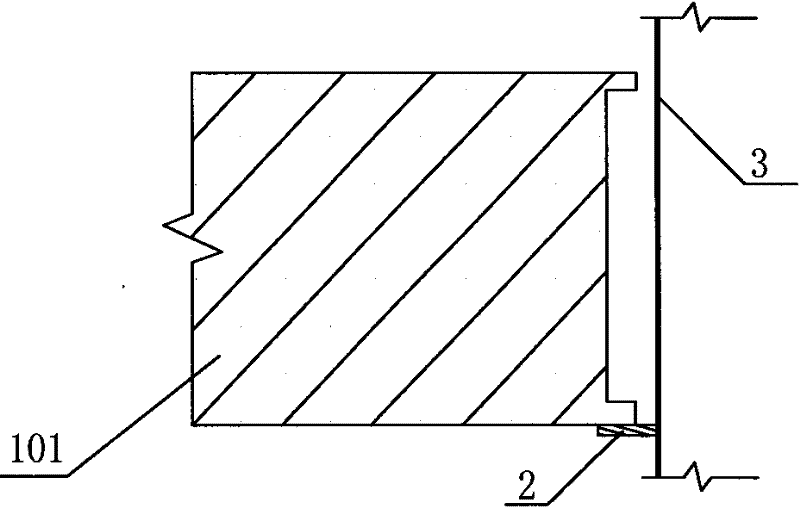

Automatic traffic cone putting device

InactiveCN102400444AIncrease placement speedEnsure safetyTraffic signalsRoad signsMonitoring systemSimulation

The invention relates to an automatic traffic cone putting device, which belongs to the field of traffic machinery, and comprises a cone putting device, a suspension device, a guiding device and a supporting device, wherein the suspension device and the guiding device are arranged at the two ends of the cone putting device, and the supporting device is arranged at the bottom of the cone putting device. Compared with the prior art, the automatic traffic cone putting device provided by the invention has a novel structure and a reasonable design, is simple and convenient to install and maintain, is easy to operate, is flexible to move, and is convenient to regulate and control, a large number of labor can be saved, the speed for putting traffic cones can be obviously improved, the safety of workers can be effectively guaranteed, simultaneously, the putting effect is ensured, stable and accurate putting of the traffic cones can be realized, the consistency in putting intervals of the traffic cones is ensured, the putting intervals can be regulated according to the need, an operator can know running conditions of devices constantly through a monitoring system, the construction safety is fully ensured, and the automatic traffic cone putting device is suitable to be promoted and applied in traffic-related engineer operation requiring putting the traffic cones and similar facilities.

Owner:北京公联洁达公路养护工程有限公司

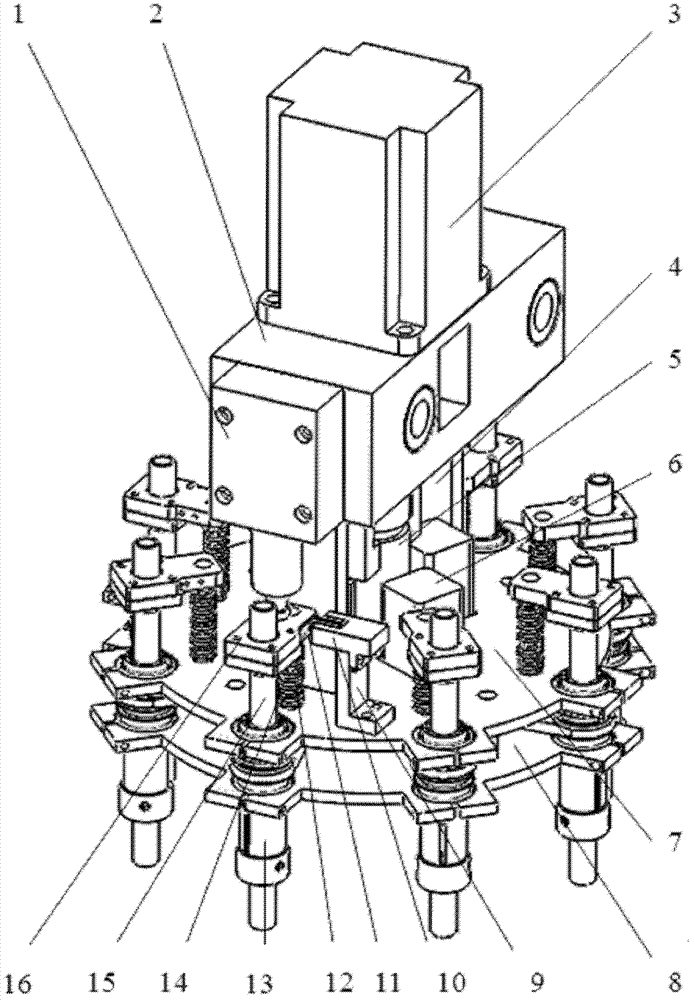

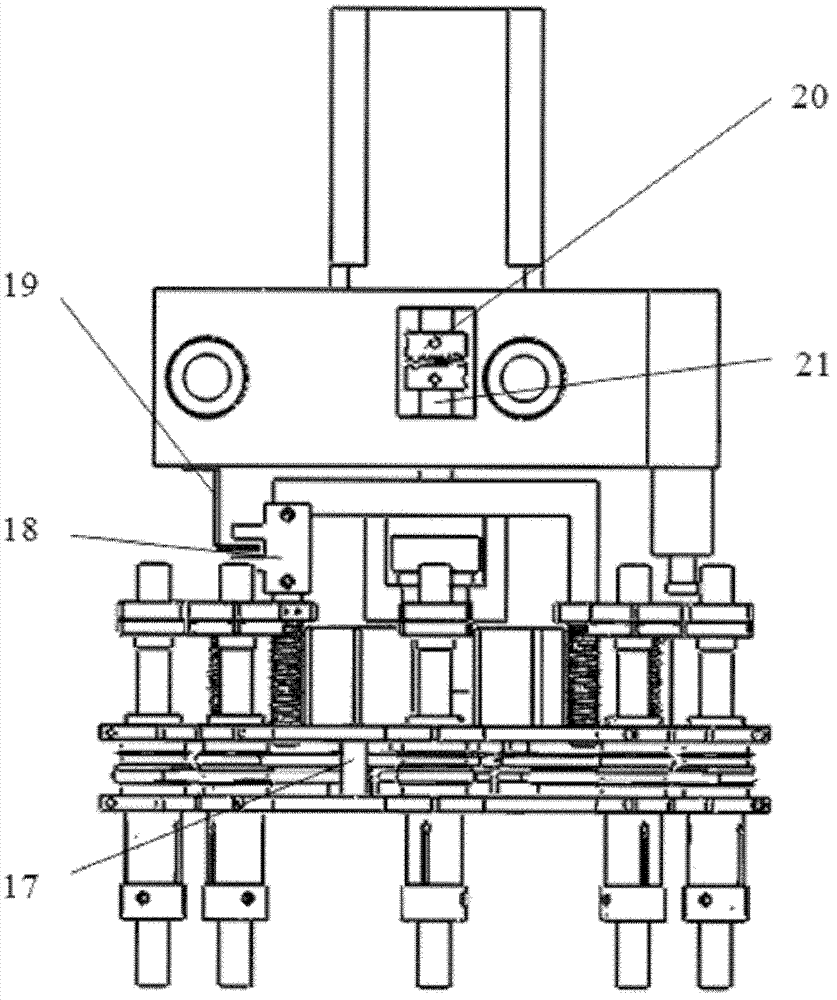

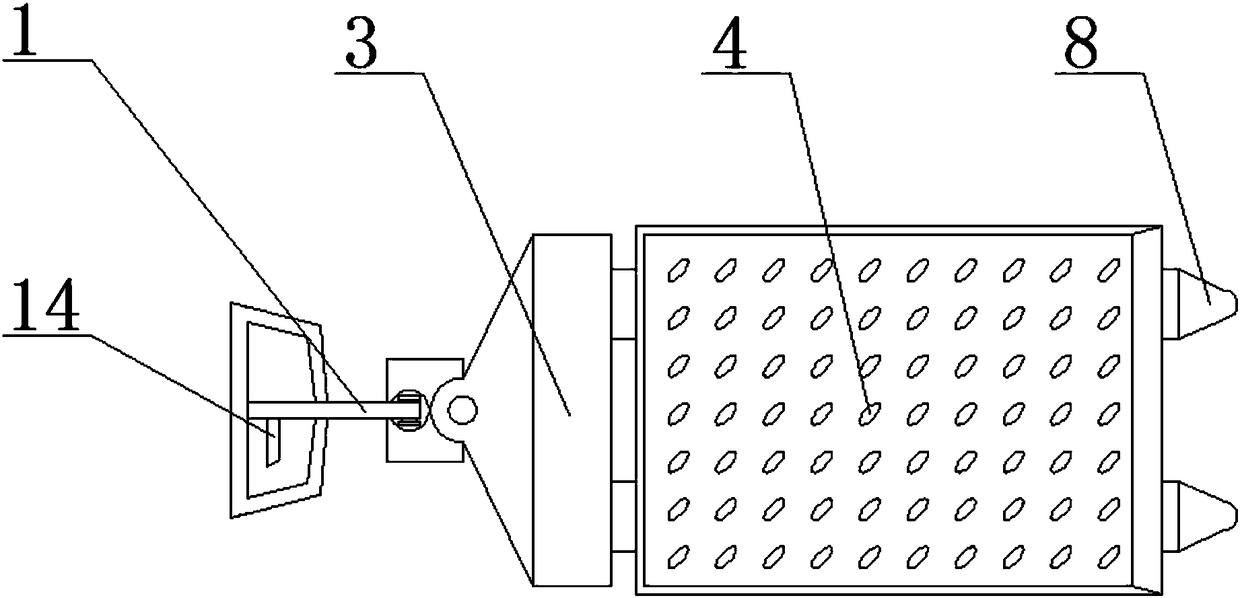

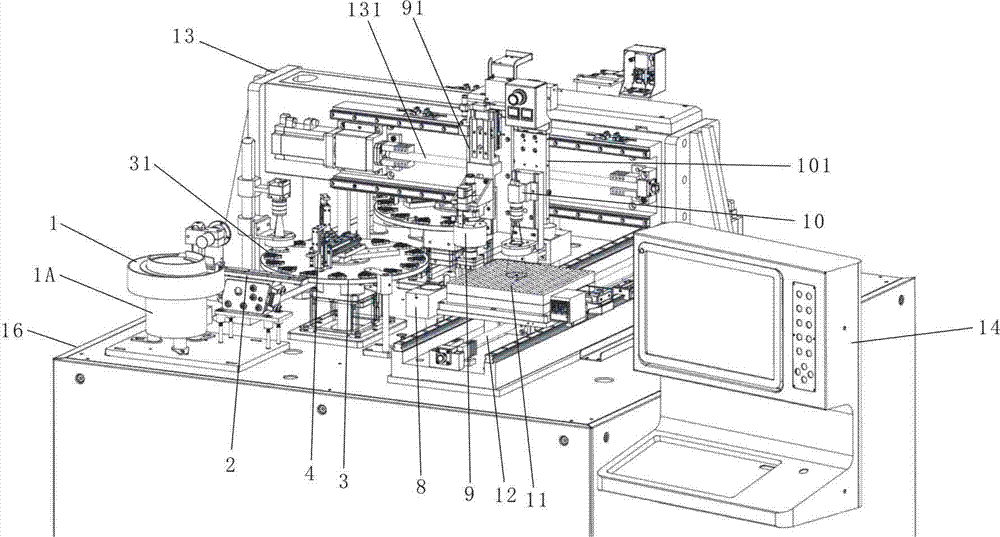

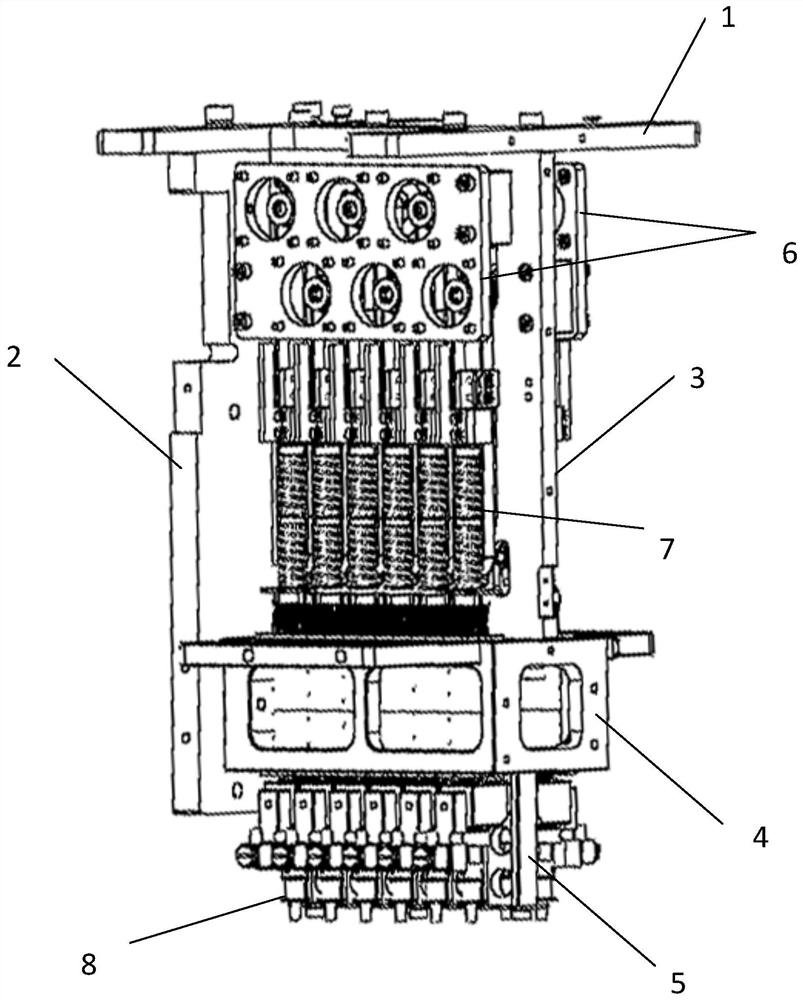

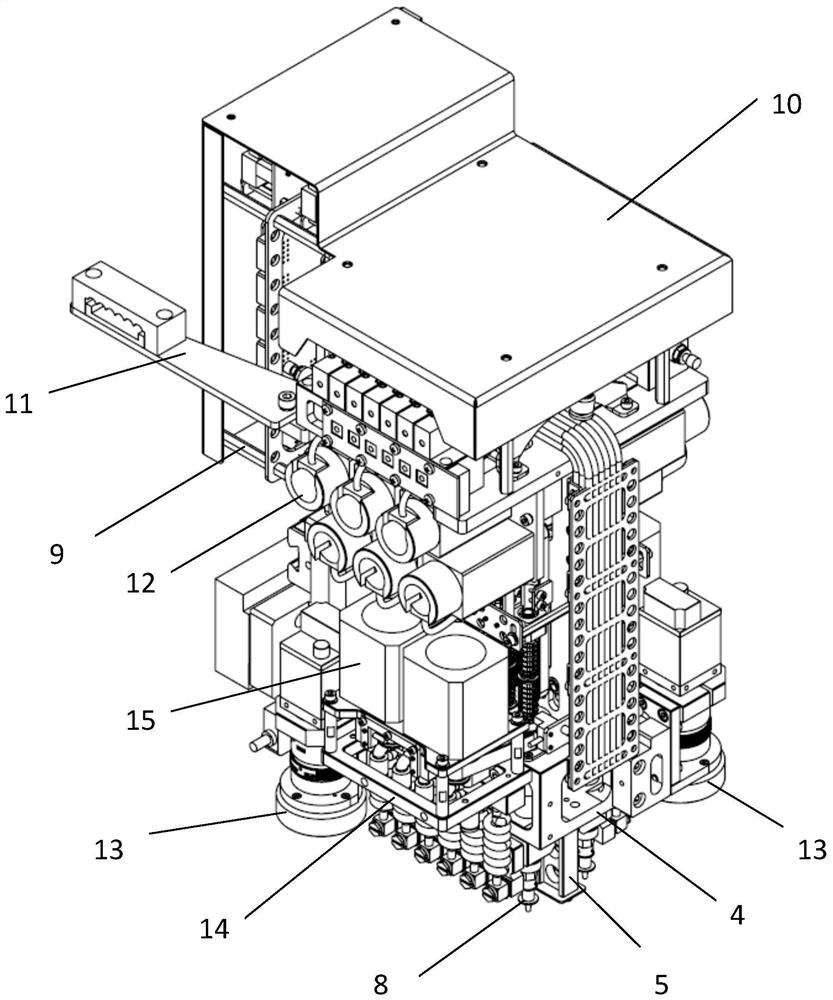

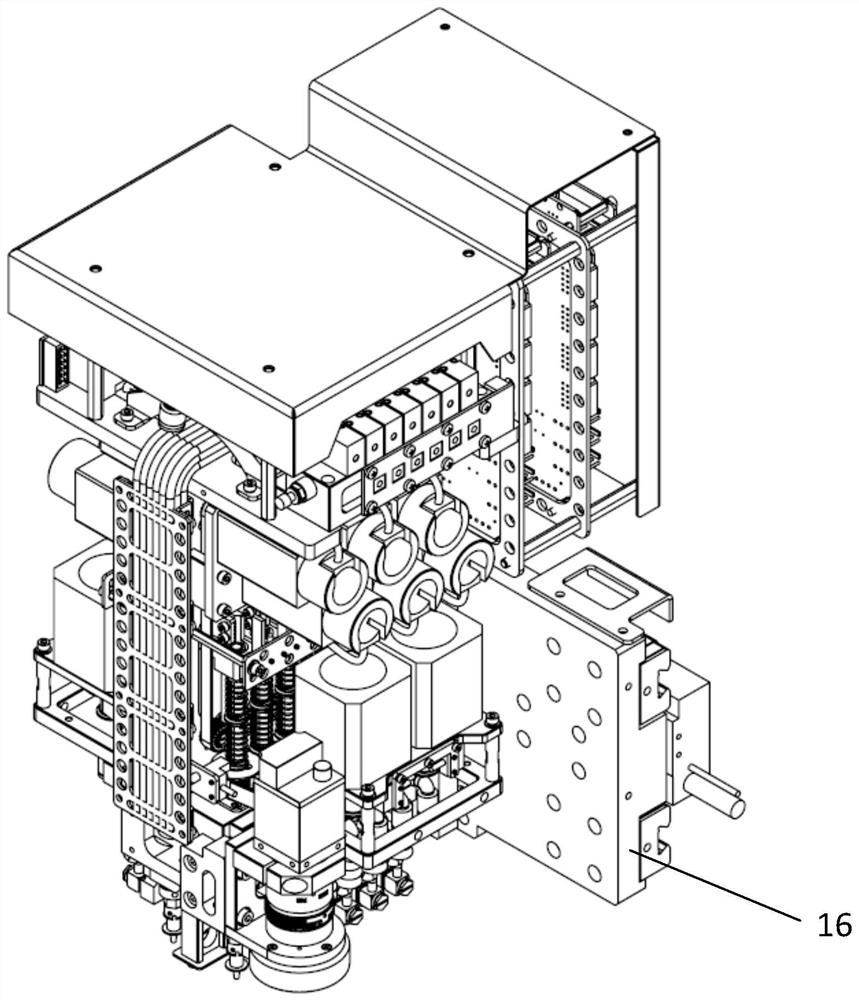

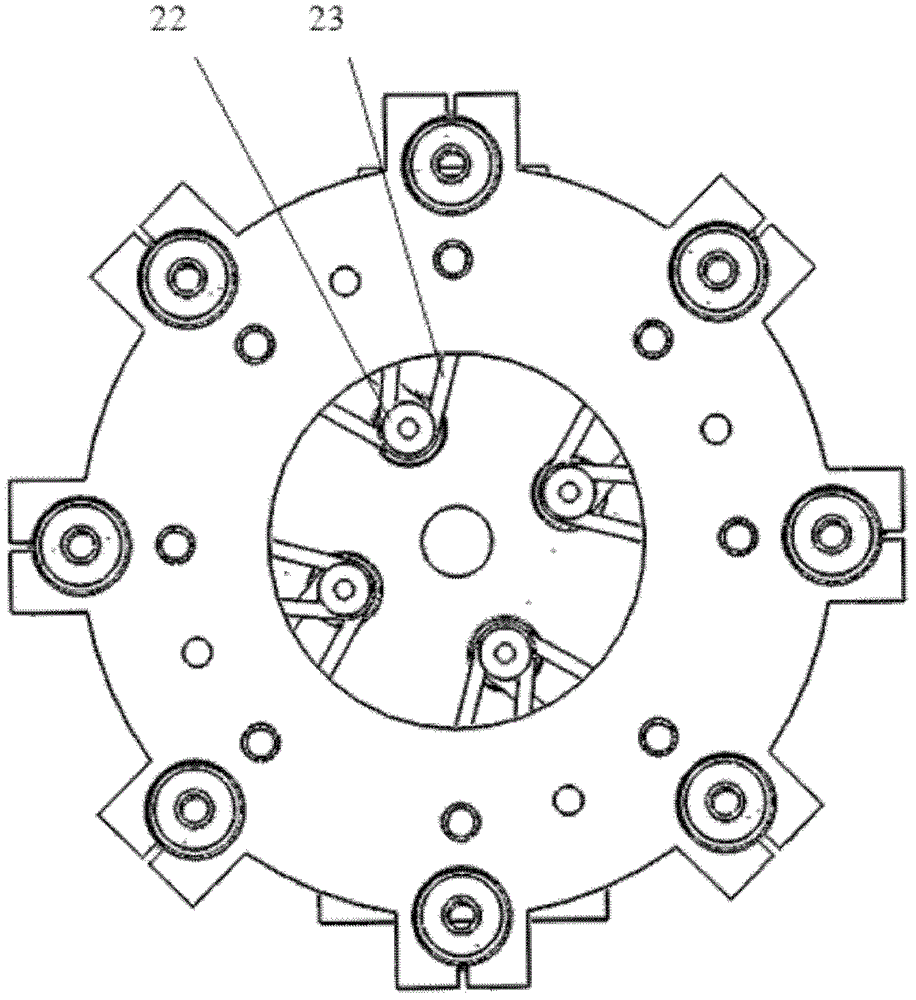

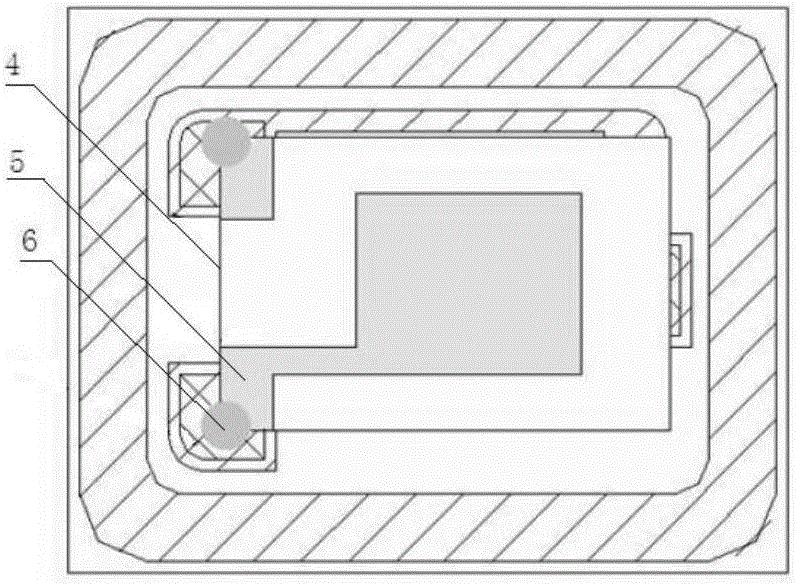

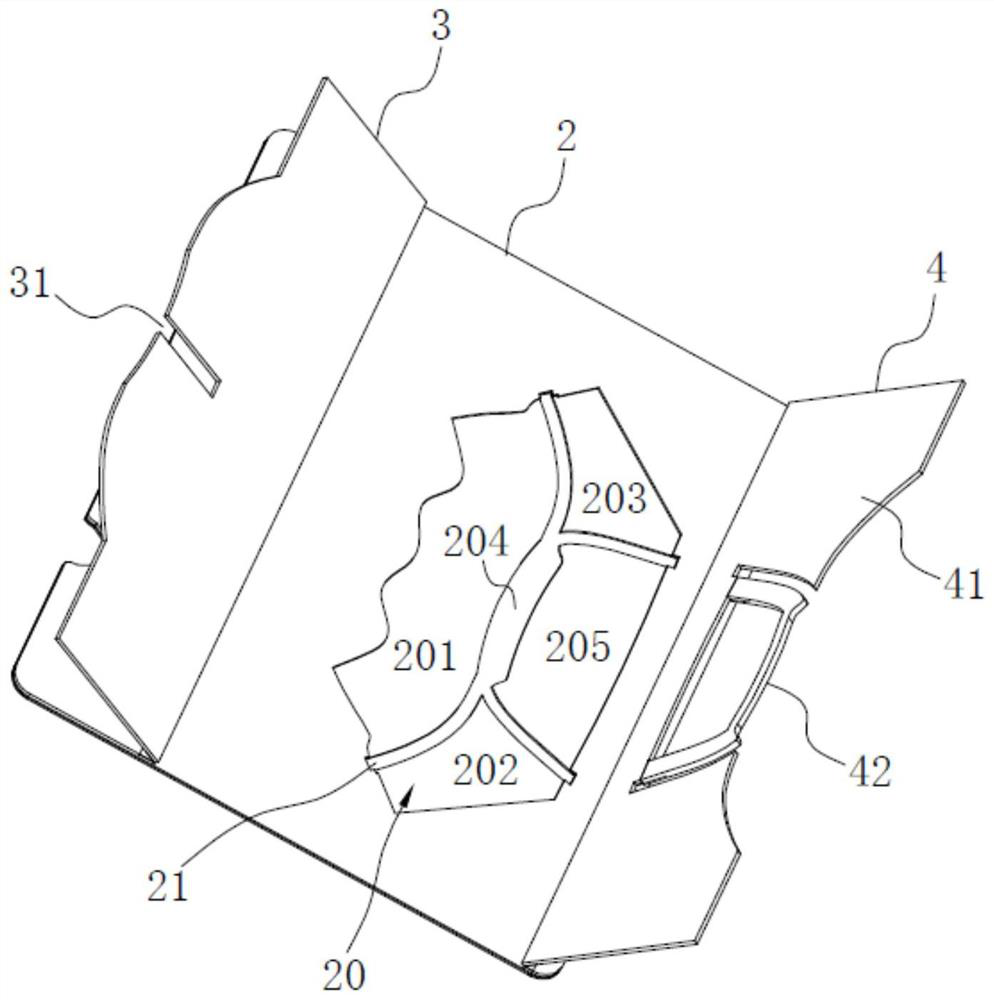

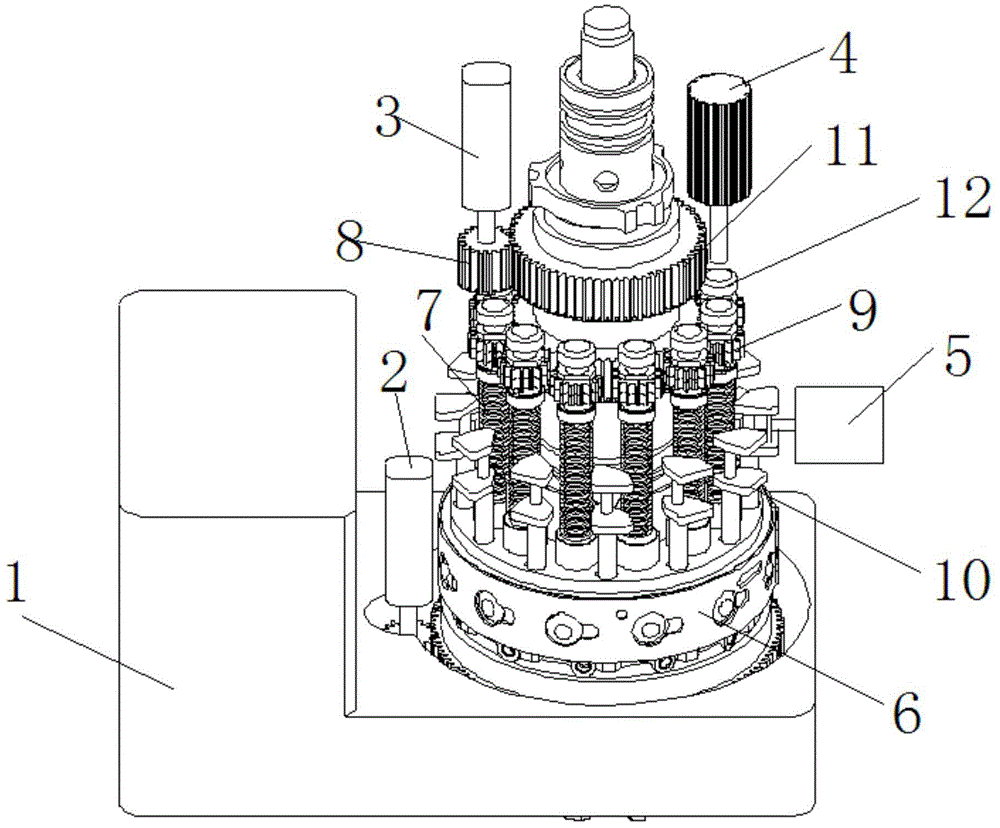

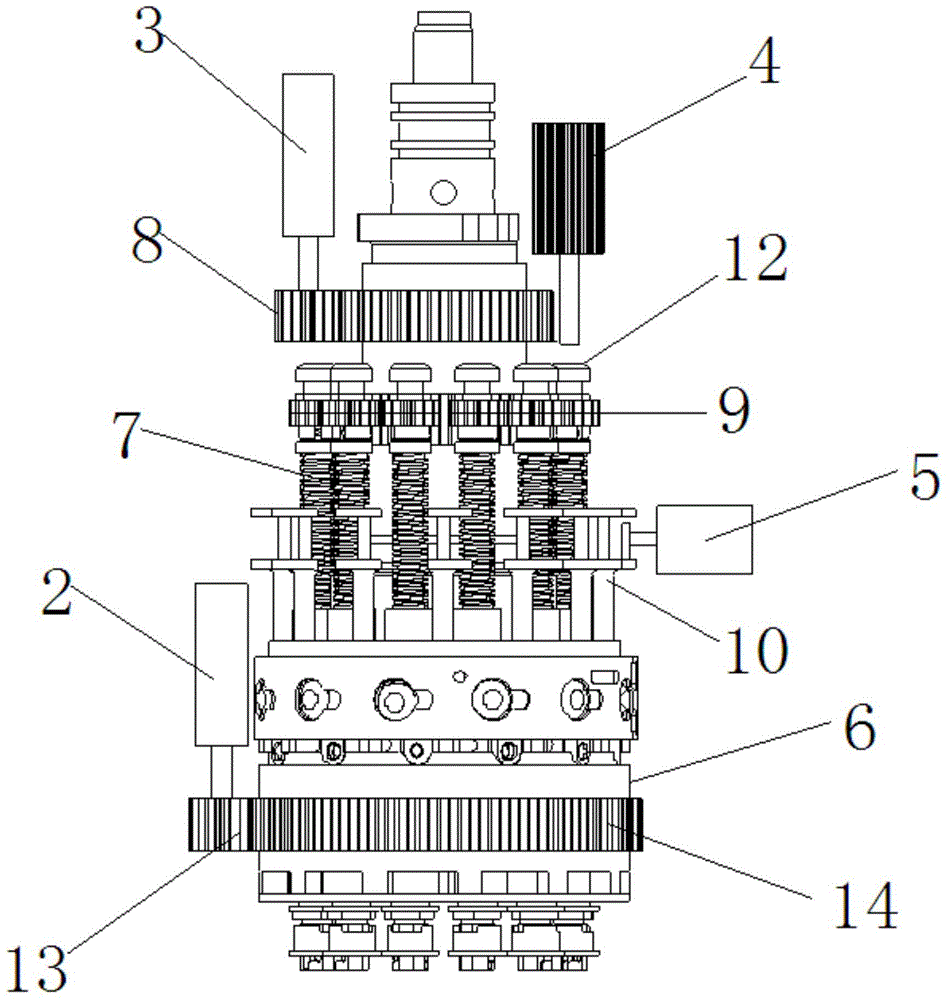

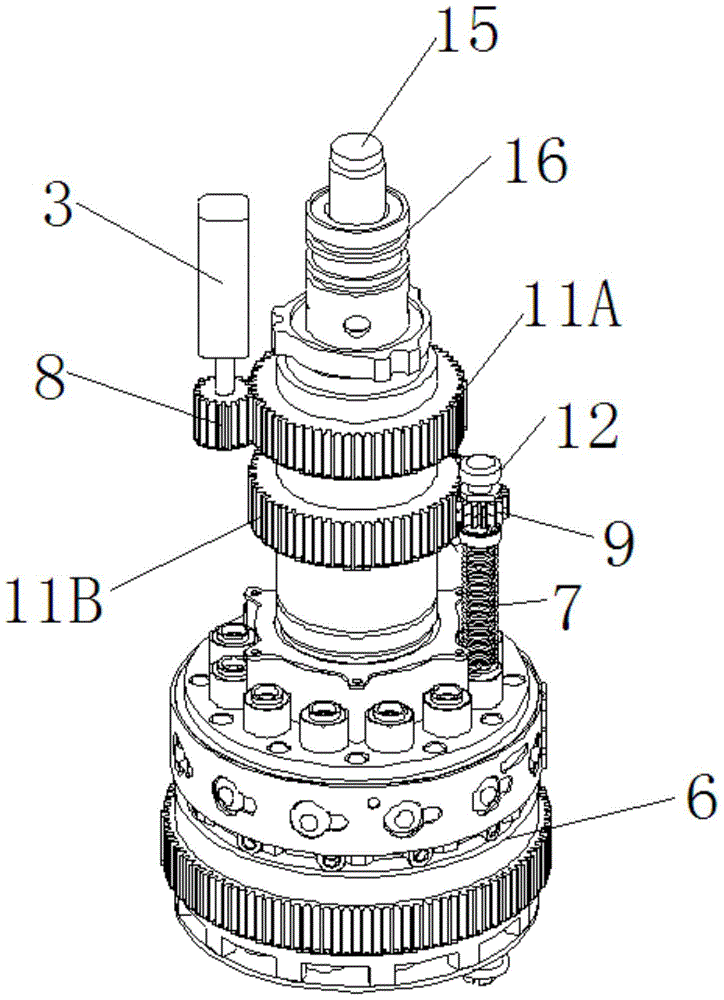

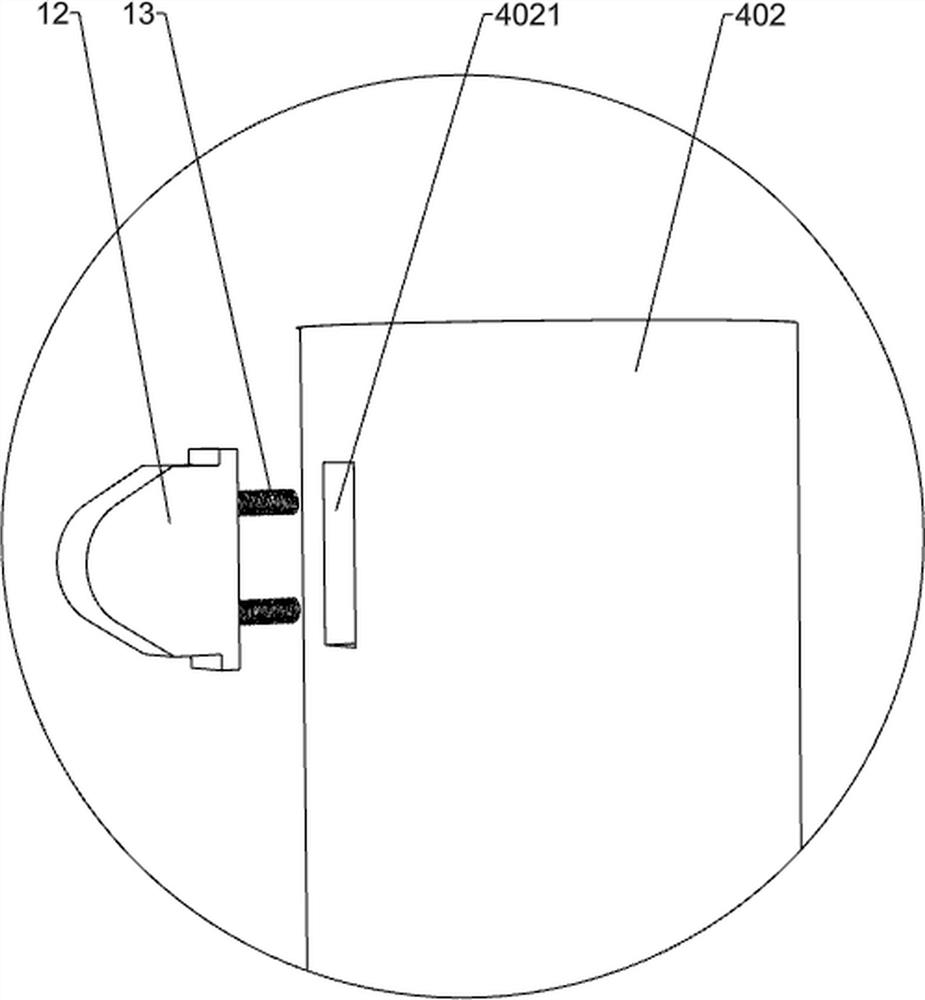

Modular high-speed mounting head for LED (light emitting diode) mounting

ActiveCN102711388AIncrease placement speedLow costPrinted circuit assemblingControl theoryHigh velocity

The invention relates to the field of chip mounters of electronic assembly, in particular to an economic high-speed mounting head technology for the chip mounters. The aim of the invention is to provide a mounting head with the characteristics of reasonable structural layout, simple transmission, small overall volume, light weight, high speed and low cost. A modular high-speed mounting head for LED (light emitting diode) mounting comprises a turntable rotating mechanism, a suction nozzle lifting mechanism, a suction nozzle rotating mechanism, an electrical protection and interface conversion device, and a suction nozzle. The turntable rotating mechanism comprises a mounting head fixing seat, a direct current servo motor used for providing driving force and arranged on the mounting head fixing seat, a first turntable for keeping linkage, a second turntable, a turntable connecting frame for connecting the first turntable and the output end of the direct current servo motor, and a turntable shaft.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

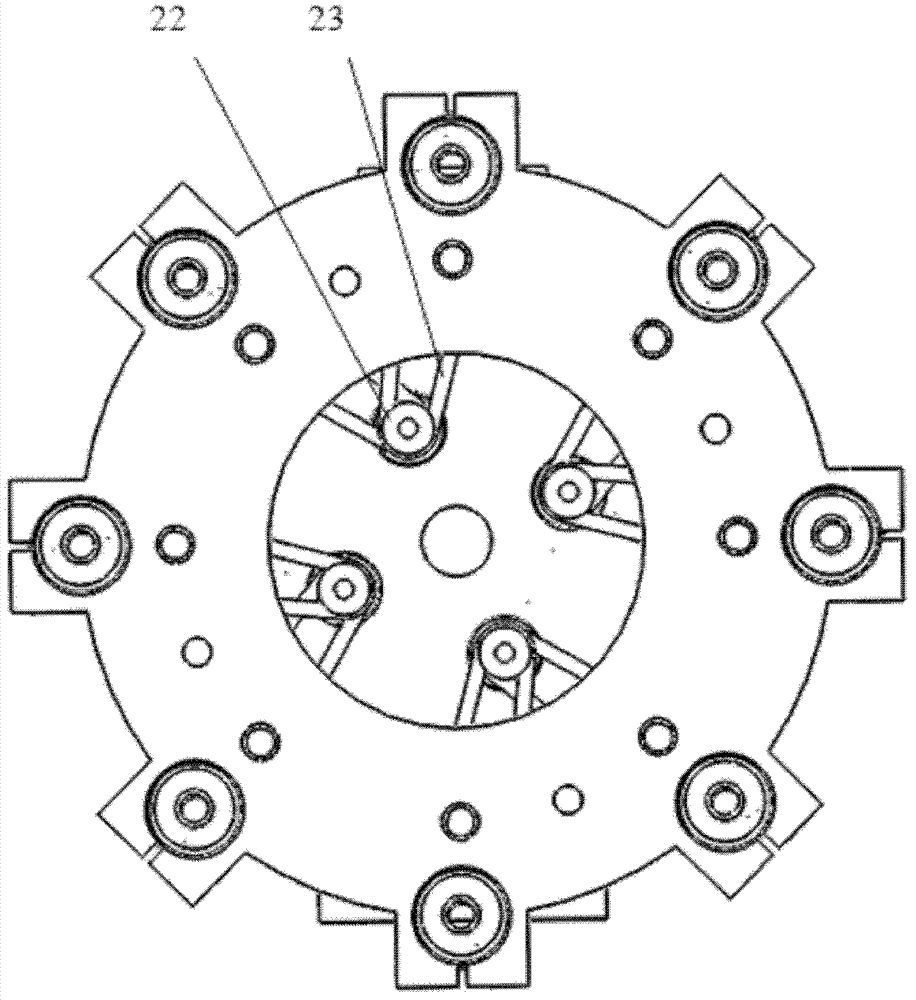

Chip mounter and bottom lens visual system thereof

ActiveCN104168721AIncrease placement speedReduce processing timePrinted circuit assemblingPhotographyEngineeringVisual perception

The invention discloses a chip mounter and a bottom lens visual system thereof. The bottom lens visual system comprises a camera installing base arranged on a chip mounter platform, a camera installing plate arranged on the camera installing base in a position adjustable mode, a camera arranged on the corresponding camera installing plate in a position adjustable mode, two opposite light source installing bases arranged on the chip mounter platform, and two parallel strip light sources rotationally arranged between the two light source installing bases. Two or more cameras can be linearly arranged along the strip light sources, and the cameras are located between the two strip light sources. Each camera corresponds to at least two paster heads, and during shooting, the cameras are located under the middle points of the connecting lines of the corresponding paster heads. The shooting time is shortened, and accordingly the pasting speed of the chip mounter is increased.

Owner:泰姆瑞(北京)精密技术有限公司

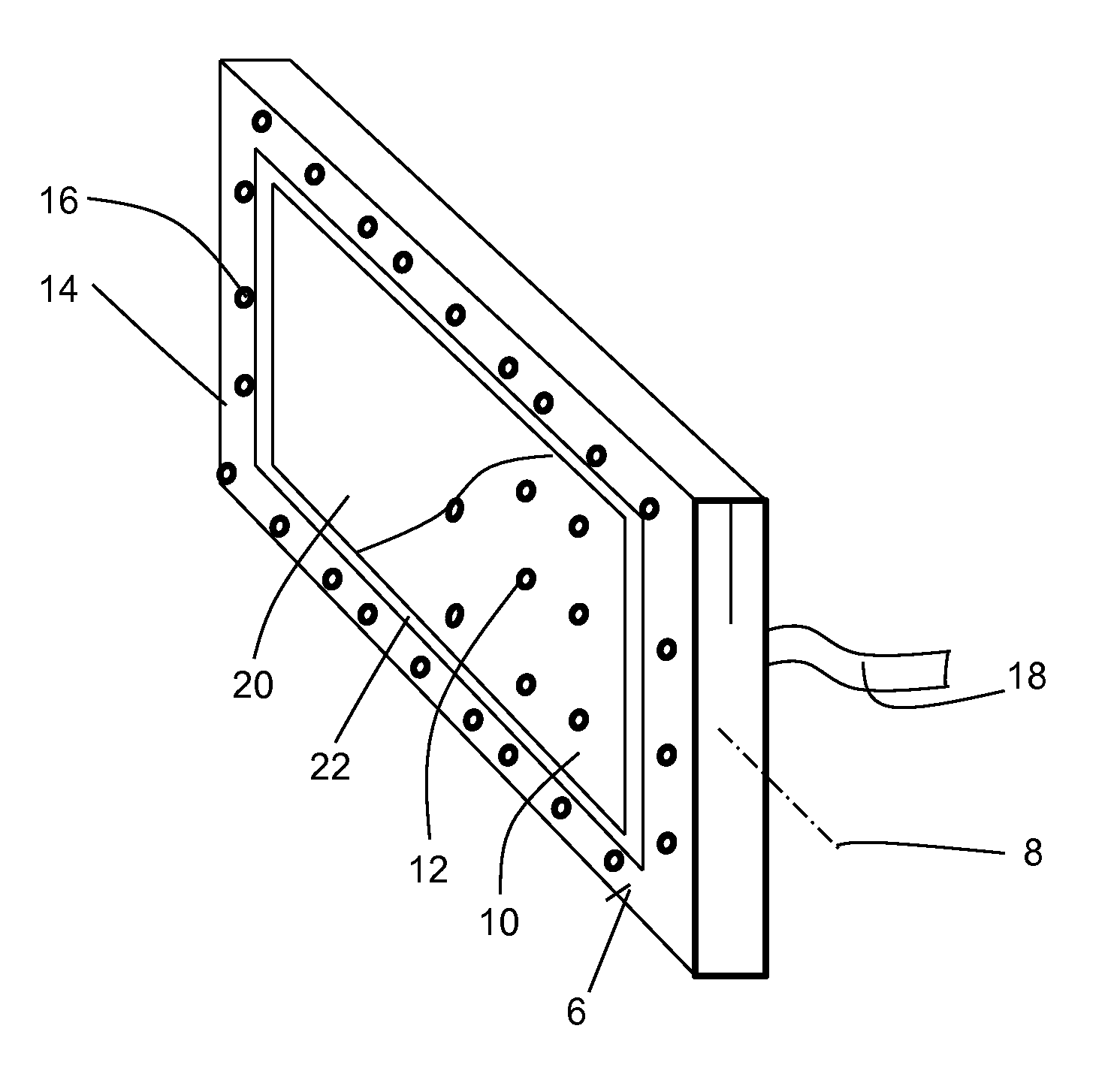

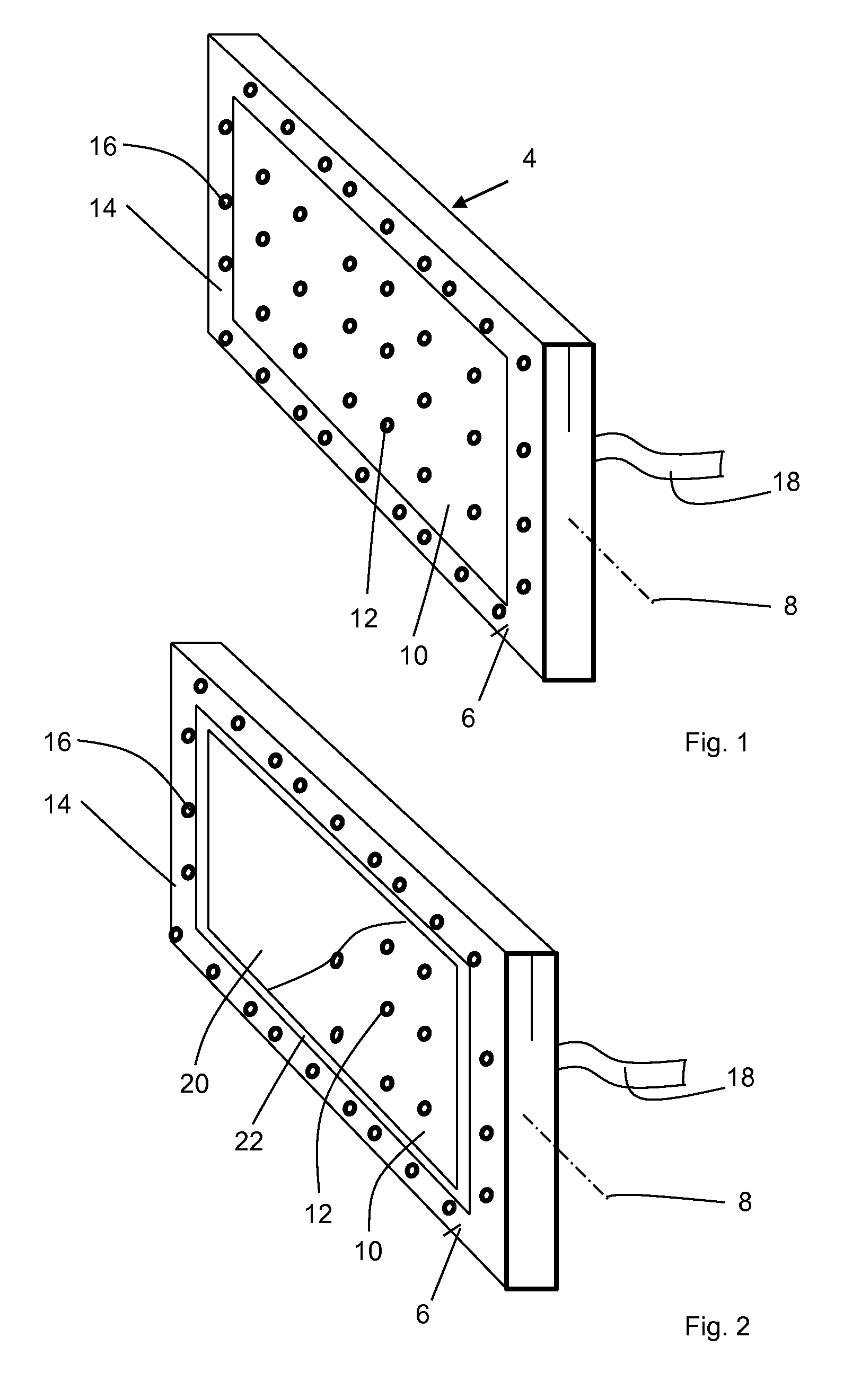

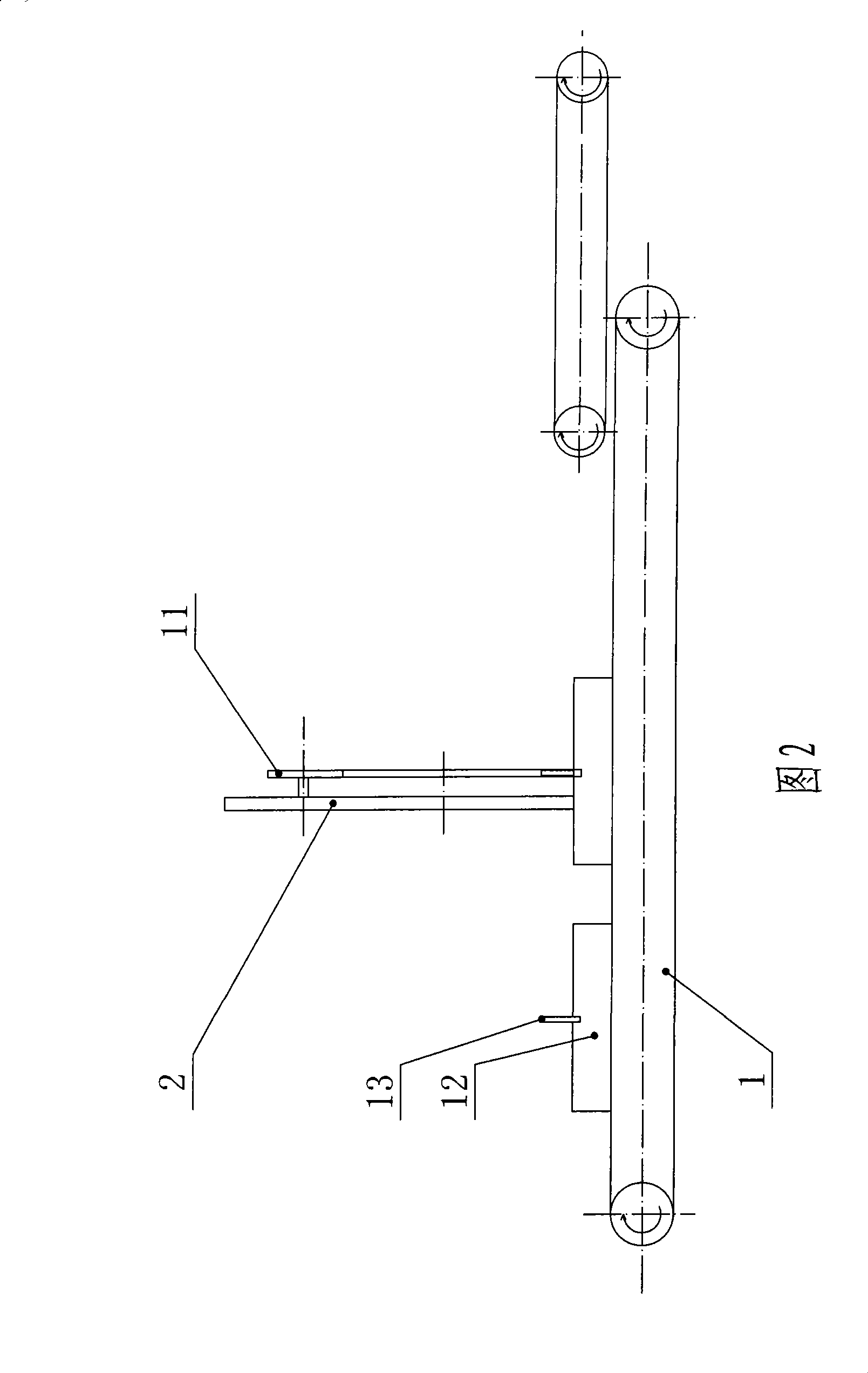

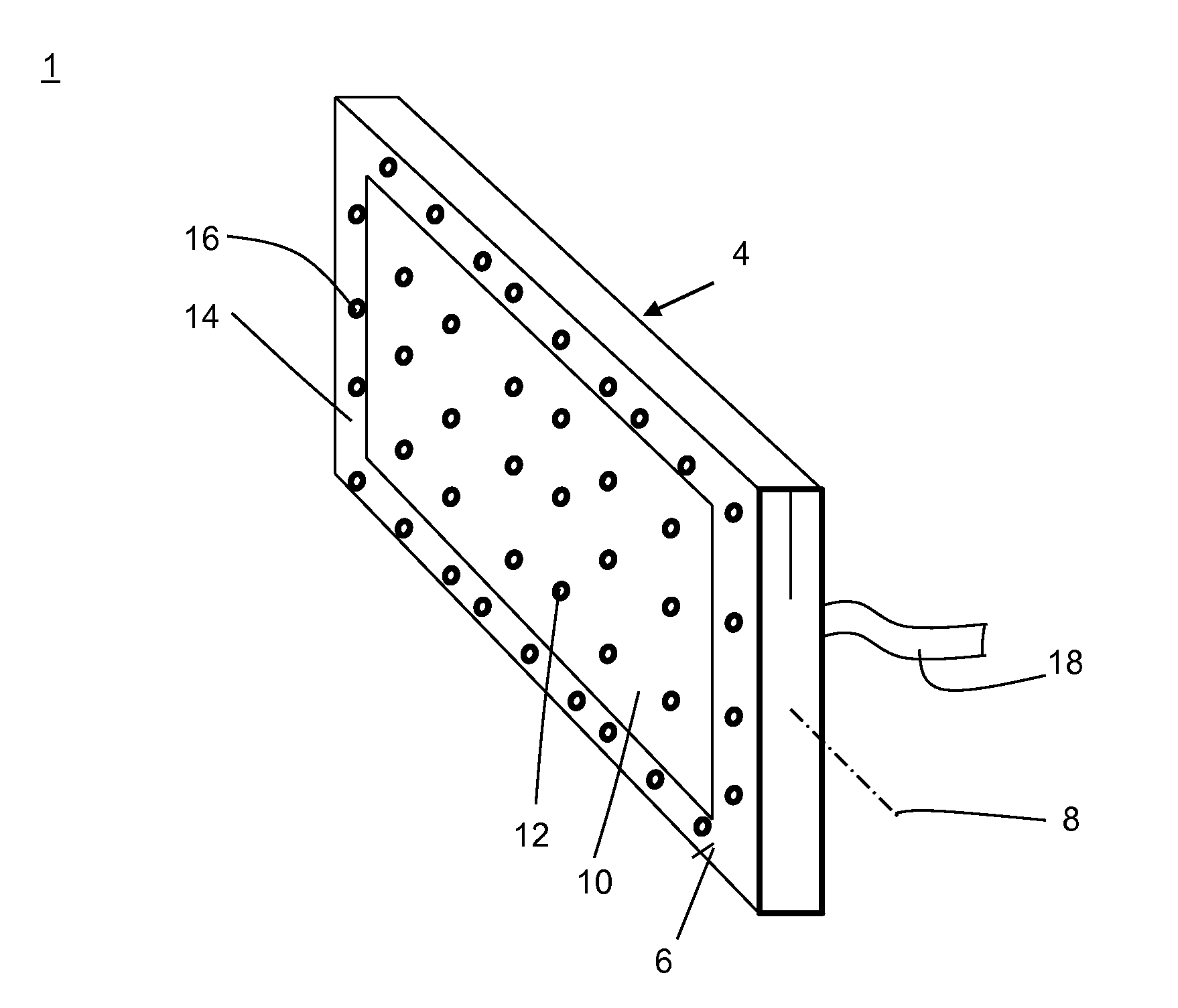

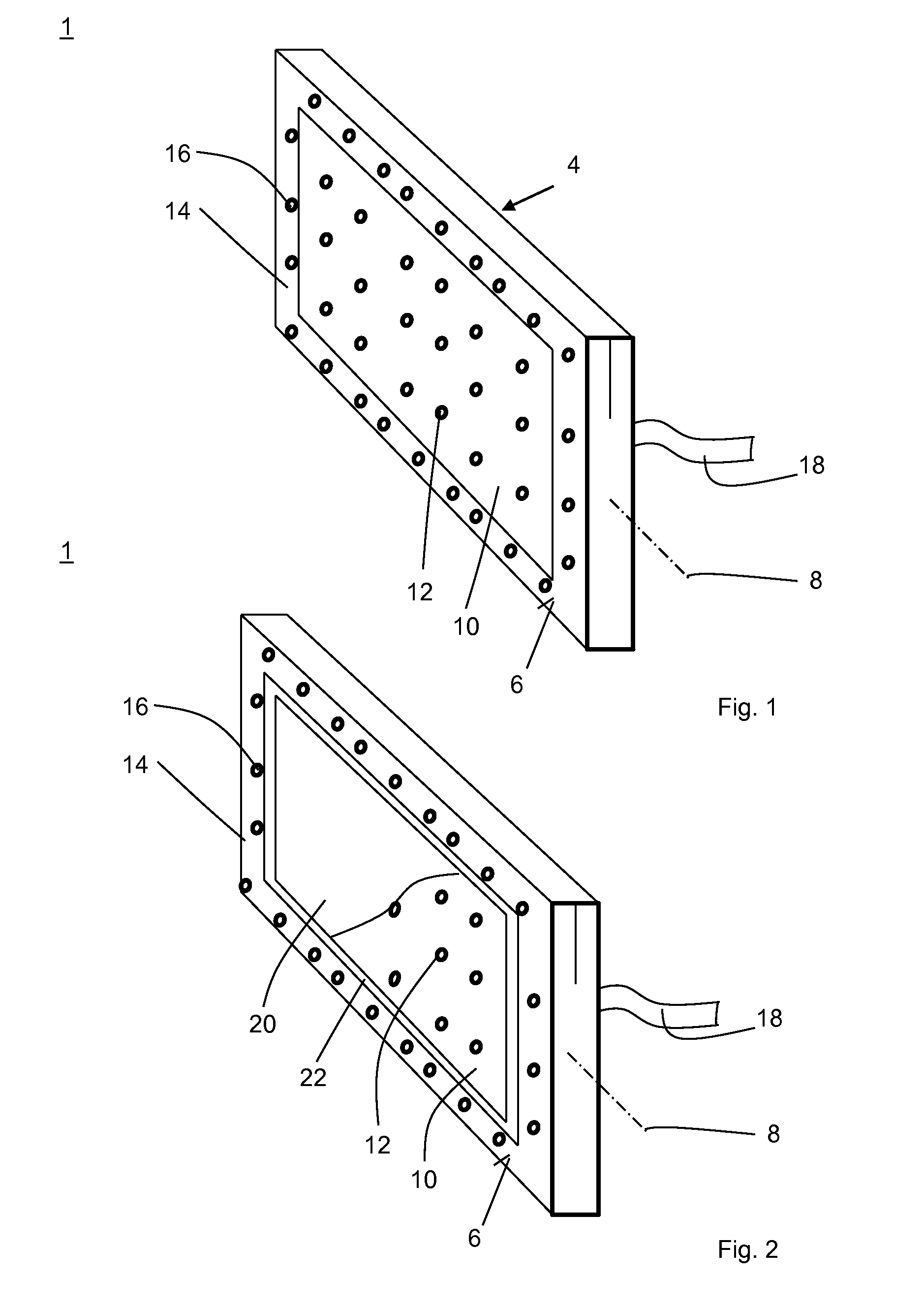

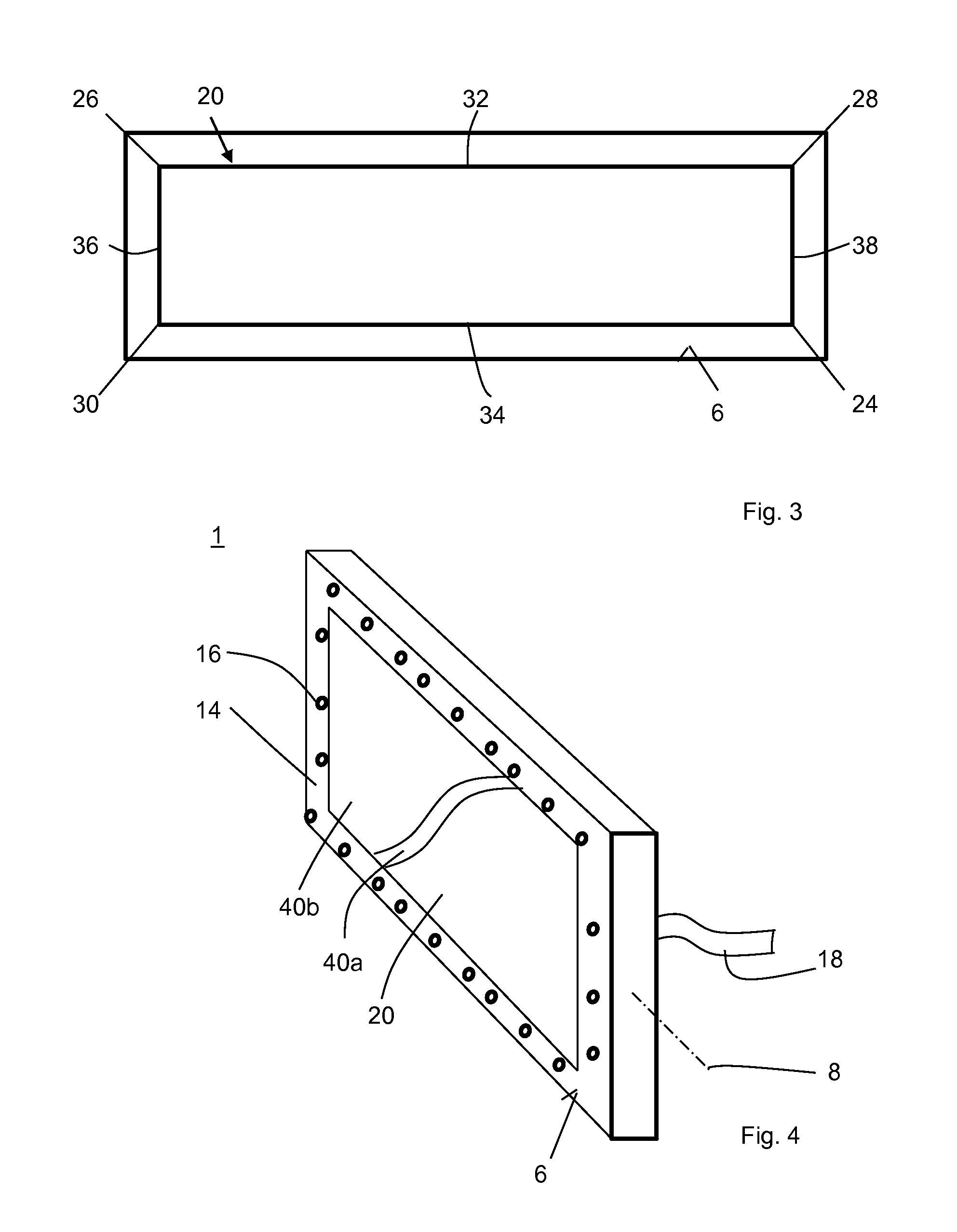

A method and a placement tool for the manufacture of a non-crimp fabric

ActiveUS20120279649A1Improve placement performanceEliminate the effects ofMechanical working/deformationLaminationEngineeringWork in process

Disclosed is a method for placing fibre-reinforced, pre-impregnated, planar semi-finished products on a placement tool for the manufacture of a non-crimp fabric, wherein a placement film is clamped on the placement tool for purposes of holding the non-crimp fabric, and by means of evacuation and / or the application of pressure is fixed in position on the placement tool and / or can be released from the latter. Also disclosed is a placement tool for the execution of such a method.

Owner:AIRBUS OPERATIONS GMBH

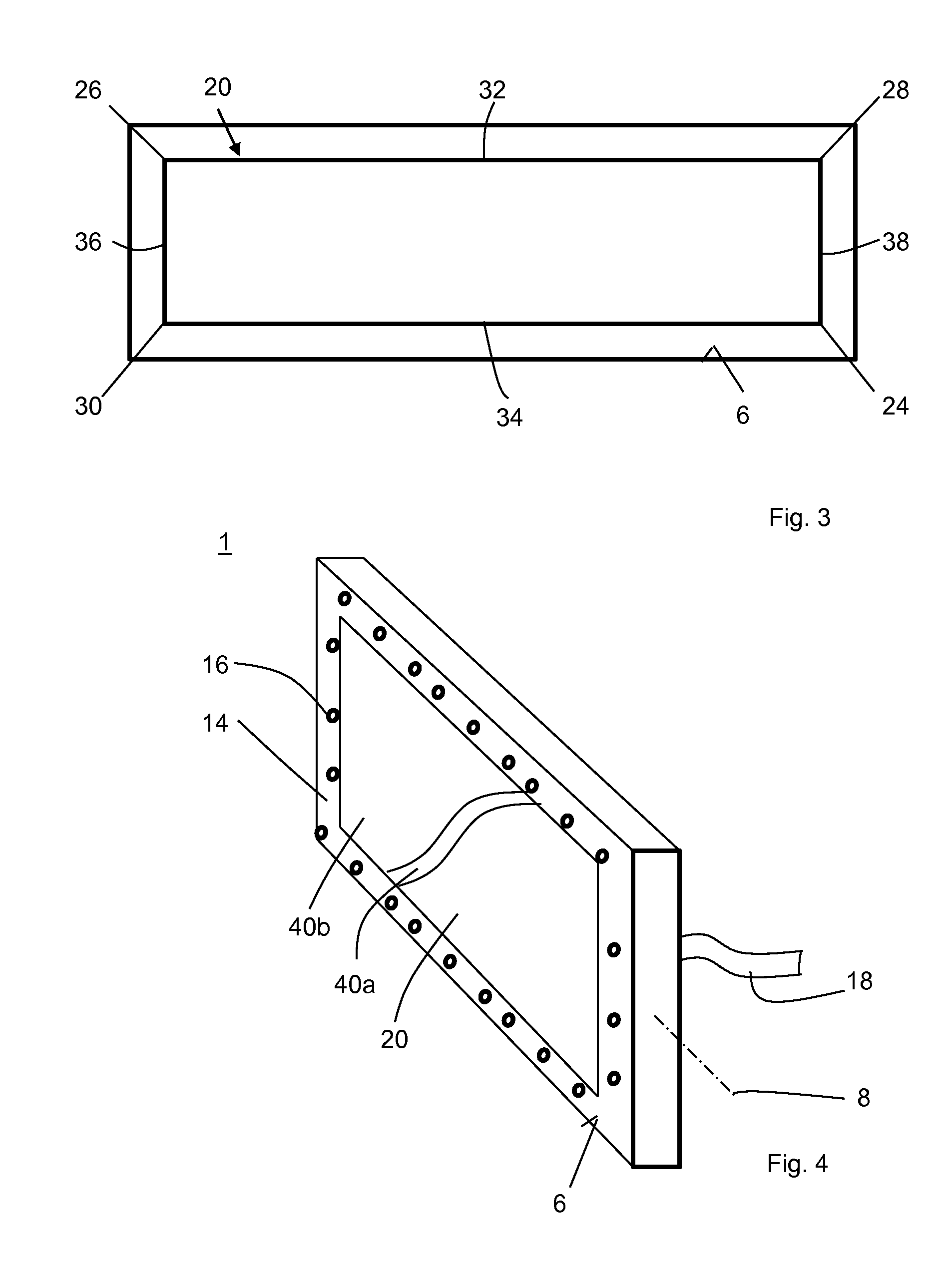

Novel loading, unloading and handling mechanical device special for multi-function forklift

InactiveCN108249354AEasy to placeAvoid damageNon-rotating vibration suppressionLifting devicesEngineeringBody frame

The invention discloses a novel loading, unloading and handling mechanical device special for a multi-function forklift. The novel loading, unloading and handling mechanical device comprises a car body frame, rollers and a decompression valve. A hydraulic jack is arranged on the left side of the car body frame, a fixed connecting frame is arranged at the joint, close to the position below the hydraulic jack, of the hydraulic jack and the car body frame, a guide wheel is arranged at the bottom of the hydraulic jack, a dragging handle is arranged over the upper left of the hydraulic jack, and the decompression valve is installed on the dragging handle. Anti-skid protrusions are arranged on the surface of an anti-skid bearing platform to facilitate the placement of goods, so that the problemthat the goods are damaged due to the goods detaching from the car body during transportation is avoided; the vibration during freight transportation is reduced by damping springs, so that the stability of the good transportation is improved, and the problem of bumping of the goods during transportation is avoided; and the fixed installation and disassembly of the damping springs are facilitated by spring fixing bolts, when not needed, the anti-skid bearing platform can be removed, and the multi-function forklift can be used as a normal hydraulic forklift.

Owner:天津显硕科技有限公司

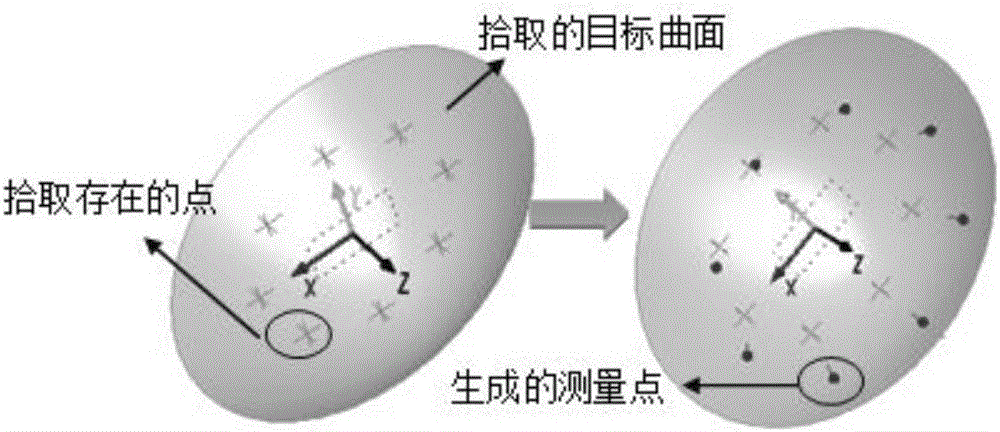

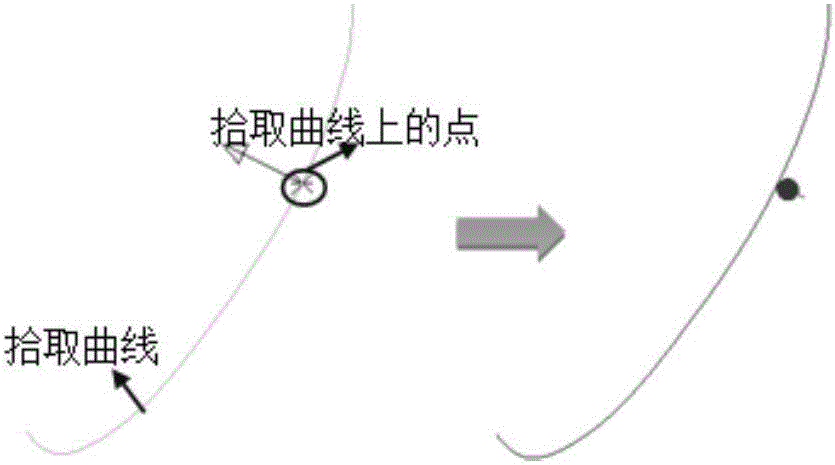

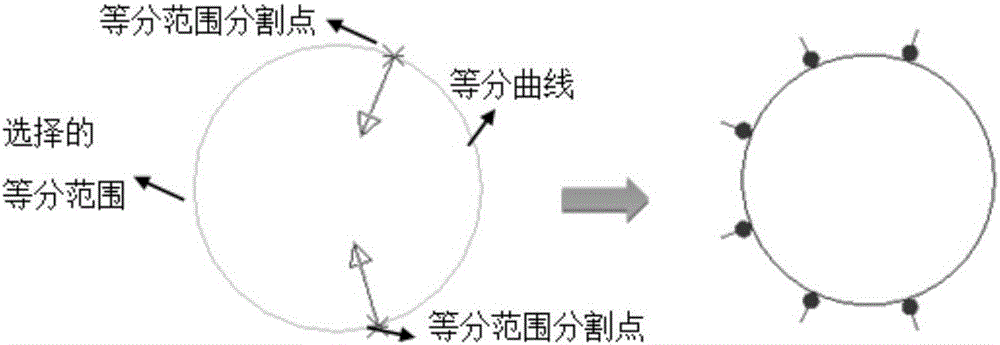

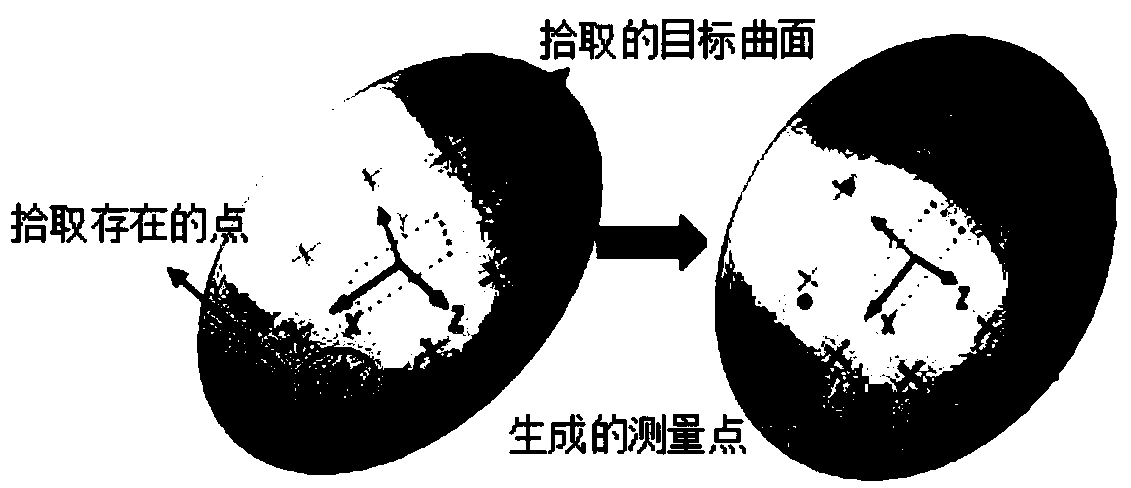

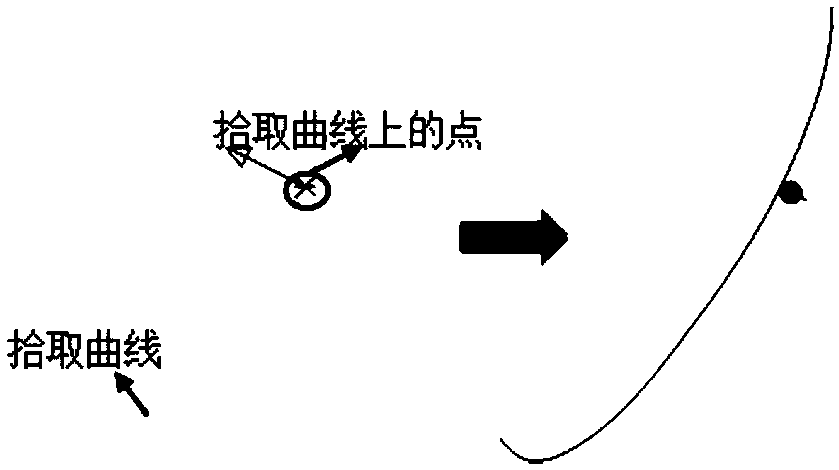

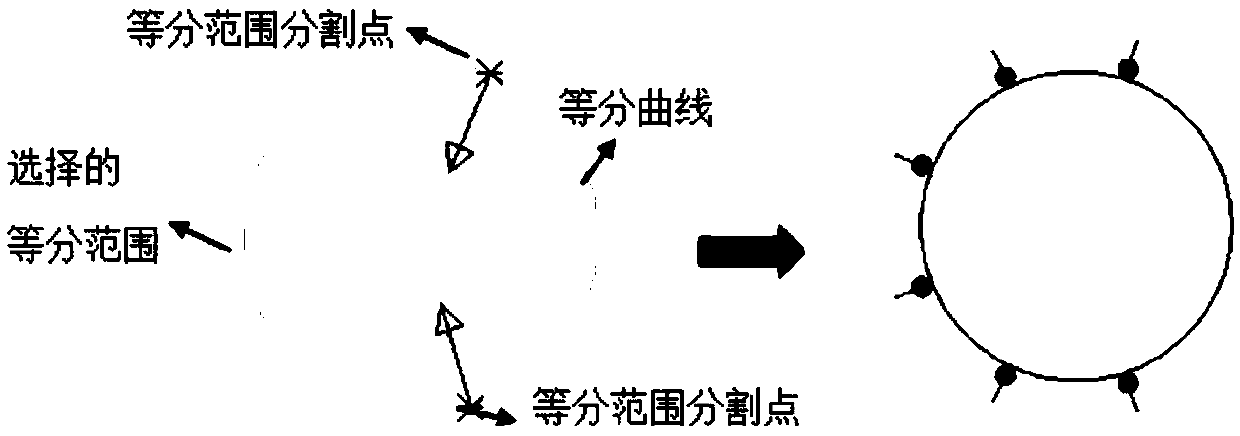

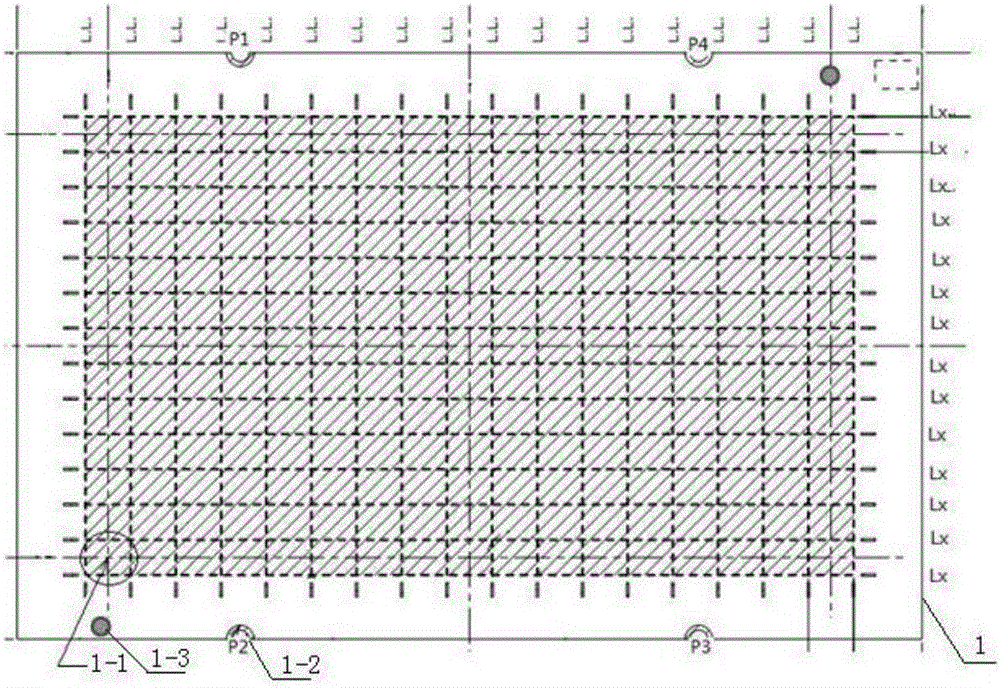

Measurement point creating method based on on-line measurement technology

ActiveCN106202843ASimple and fast operationRealize adaptive point layoutGeometric CADSpecial data processing applicationsMeasurement pointComputer science

The invention discloses a measurement point creating method based on on-line measurement technology. The method comprises following steps: obtaining point, line or surface information on a to-be-machined model to obtain curve parameter field information; obtaining position information and detection direction of measuring points according to parameter field information and curve normal direction so that the multiple measurement points are created; and generating a measurement path during an on-line measuring system and compensating the path and optimizing. The measurement point creating method based on on-line measurement technology has following beneficial effects: working load is reduced; working efficiency is raised; a usage range is wide; the method supports a plurality of types and different kinds of models to create measuring points; participation of people is minimized and error rate is lowered.

Owner:西安精雕软件科技有限公司

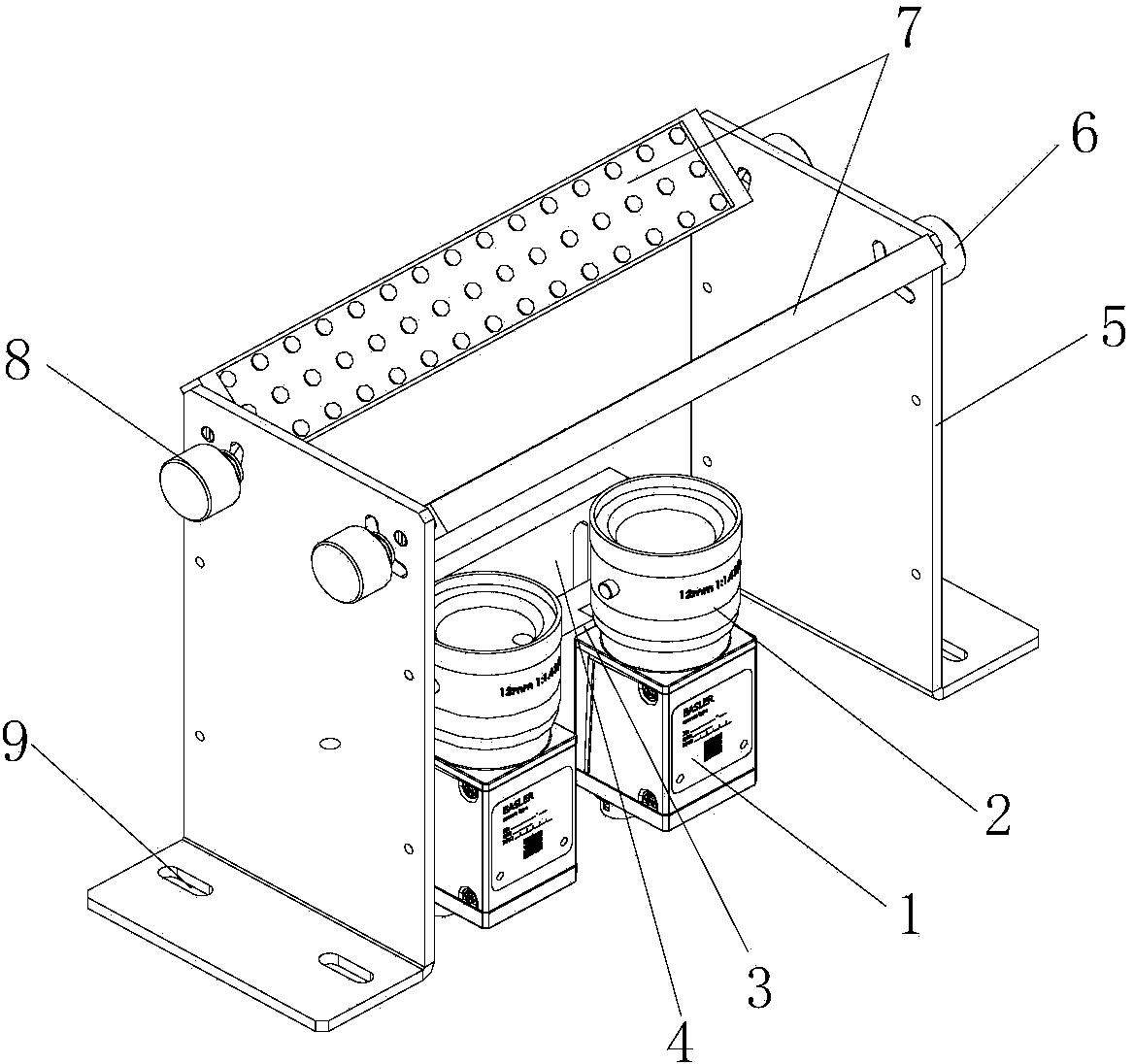

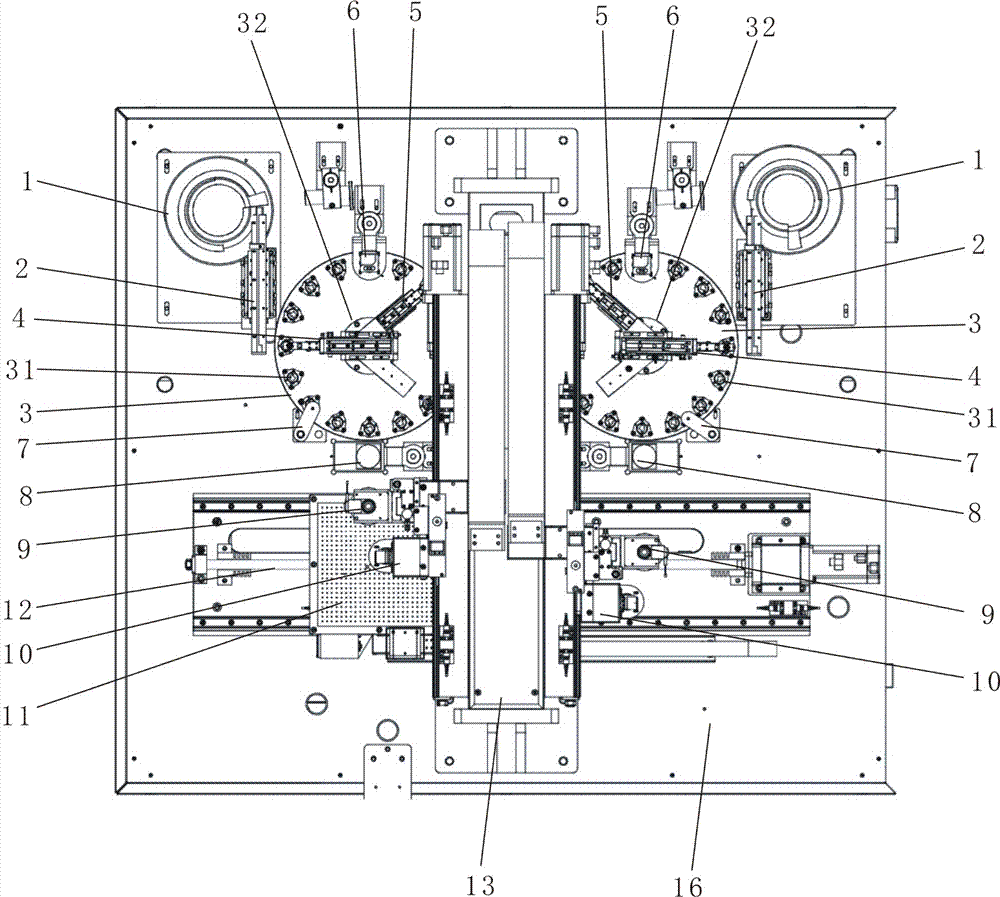

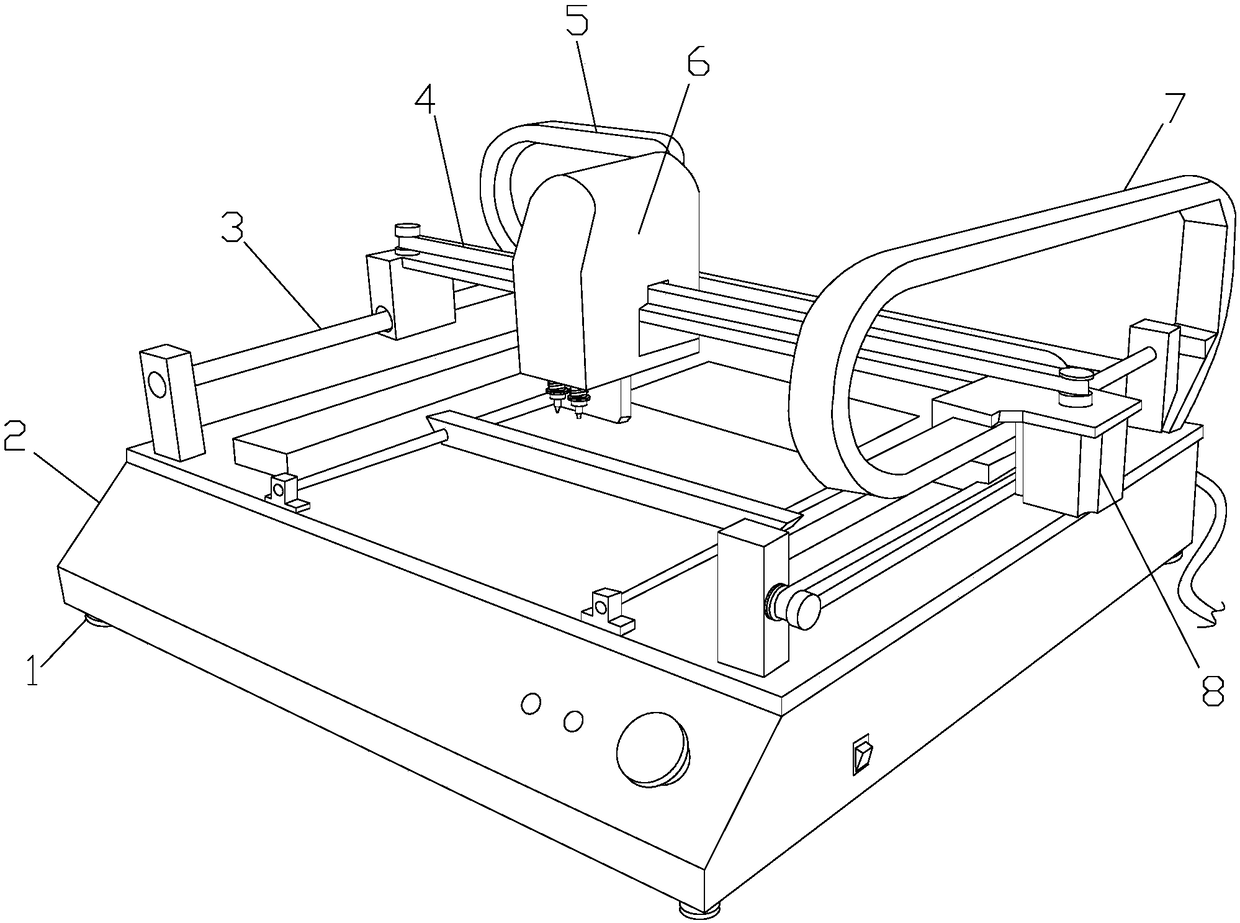

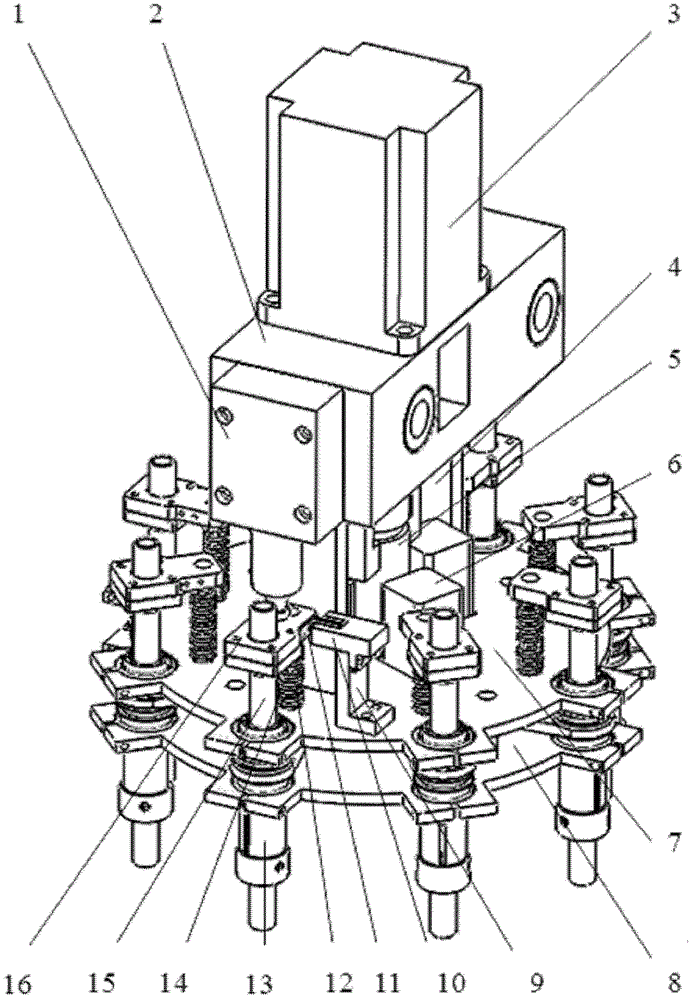

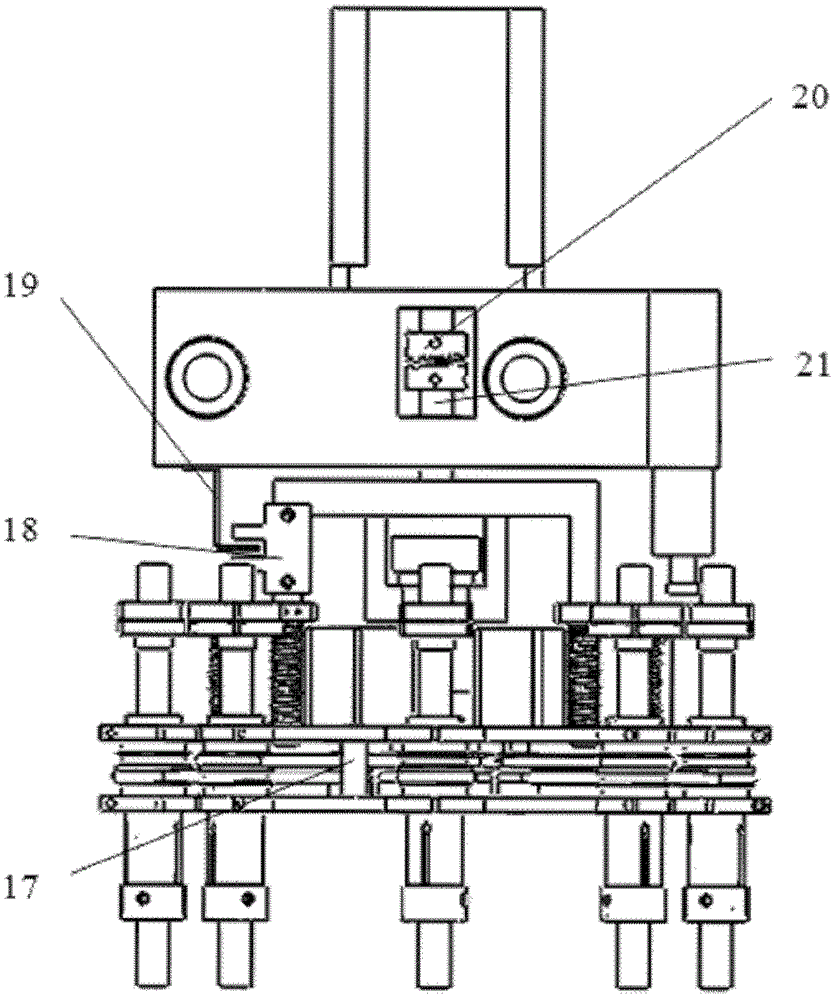

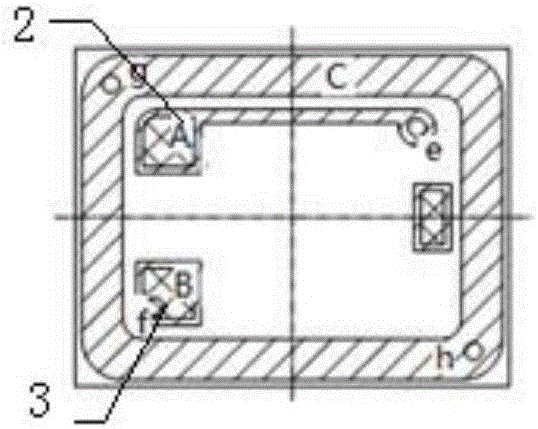

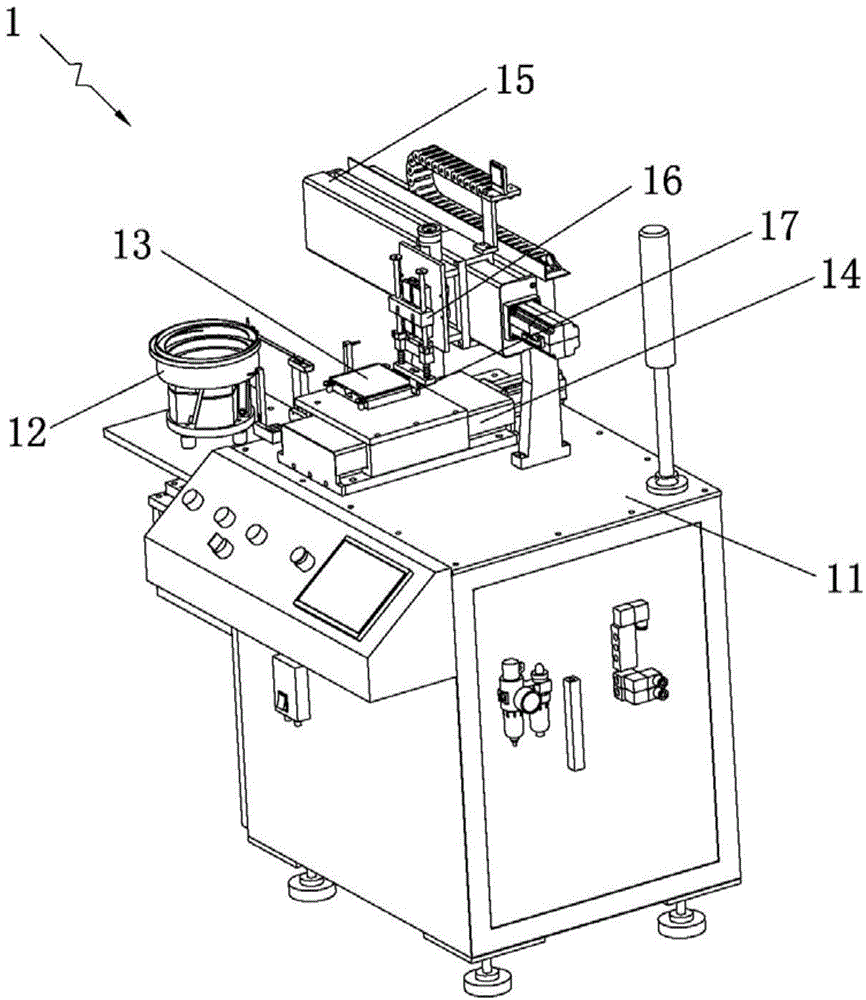

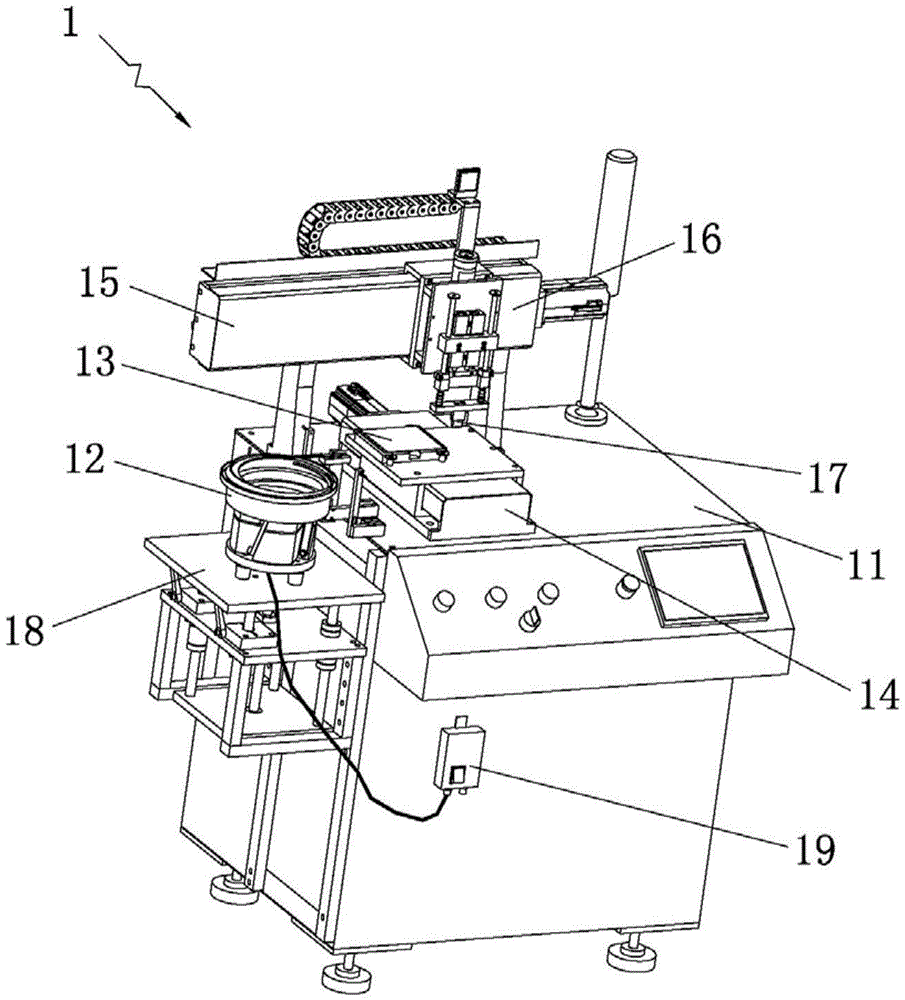

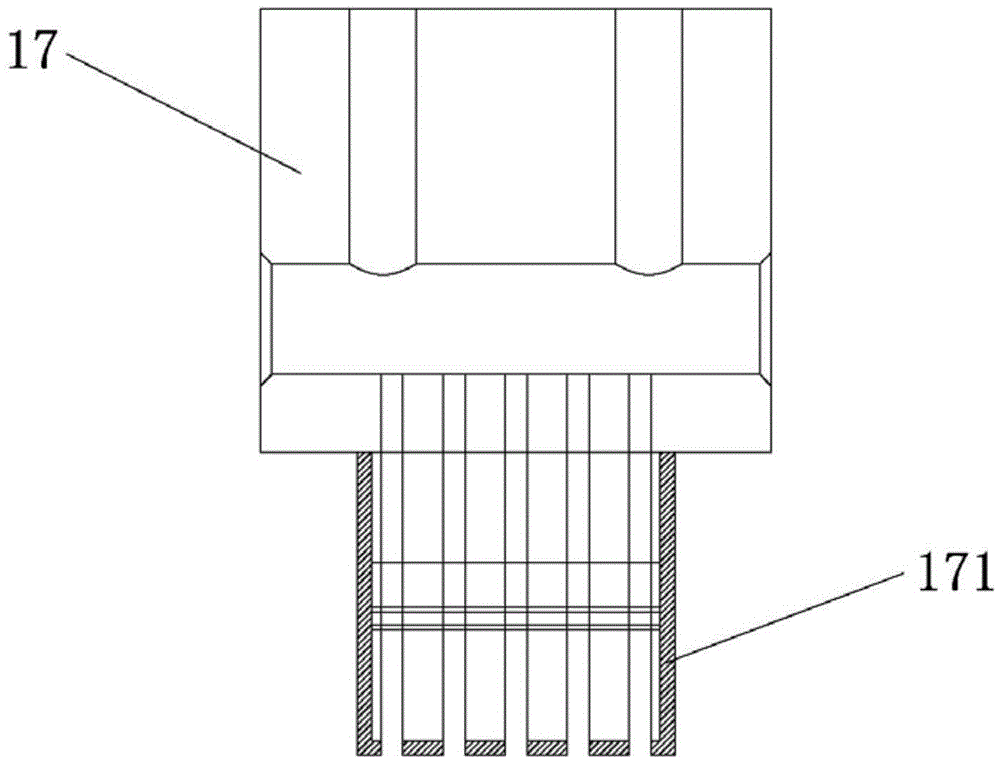

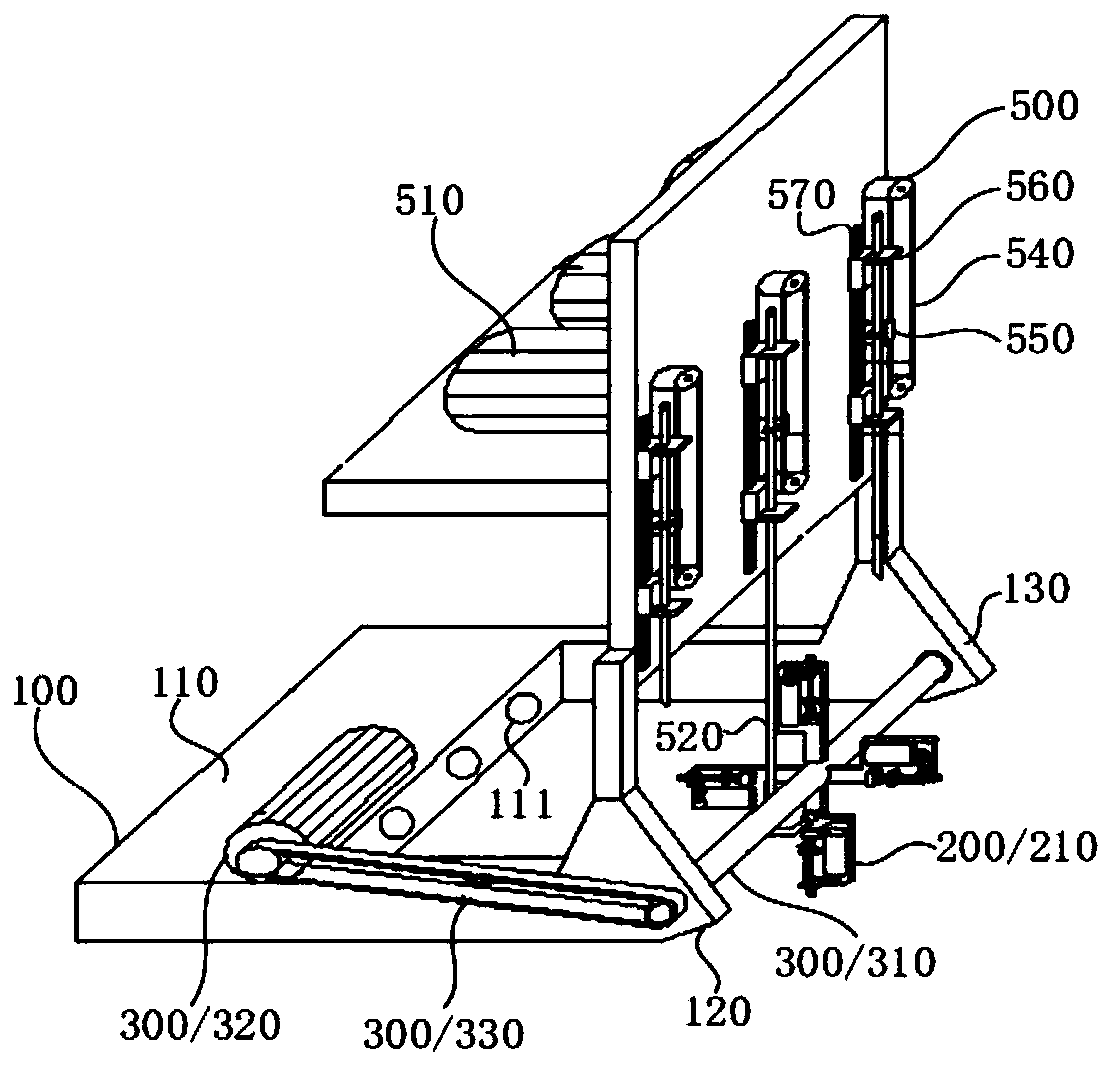

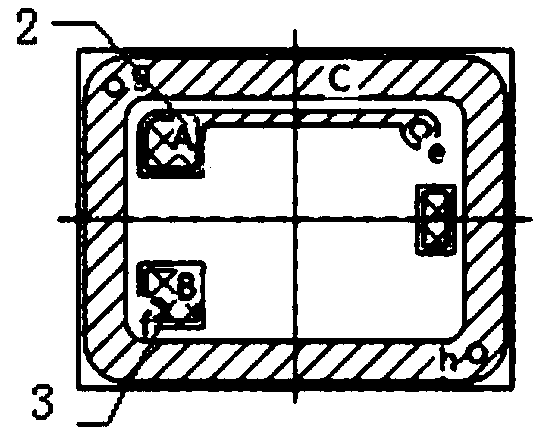

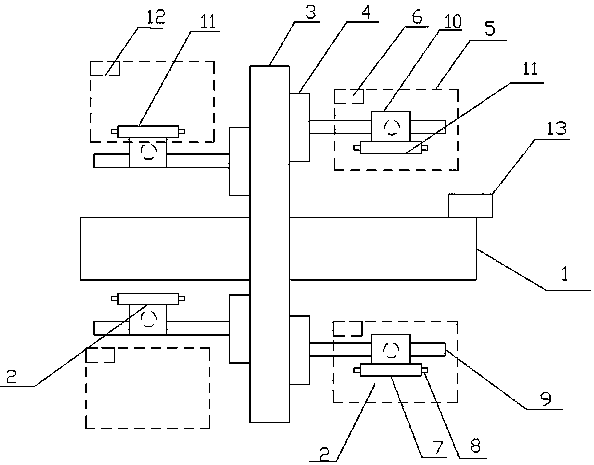

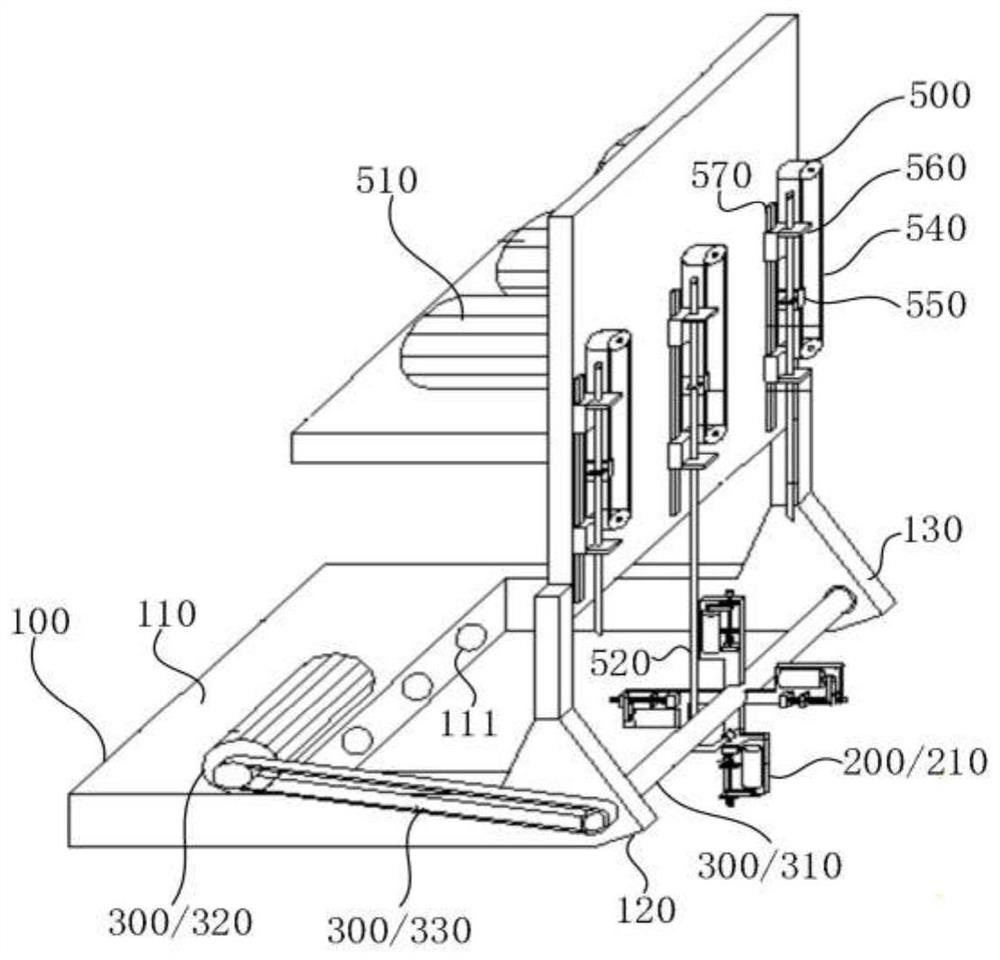

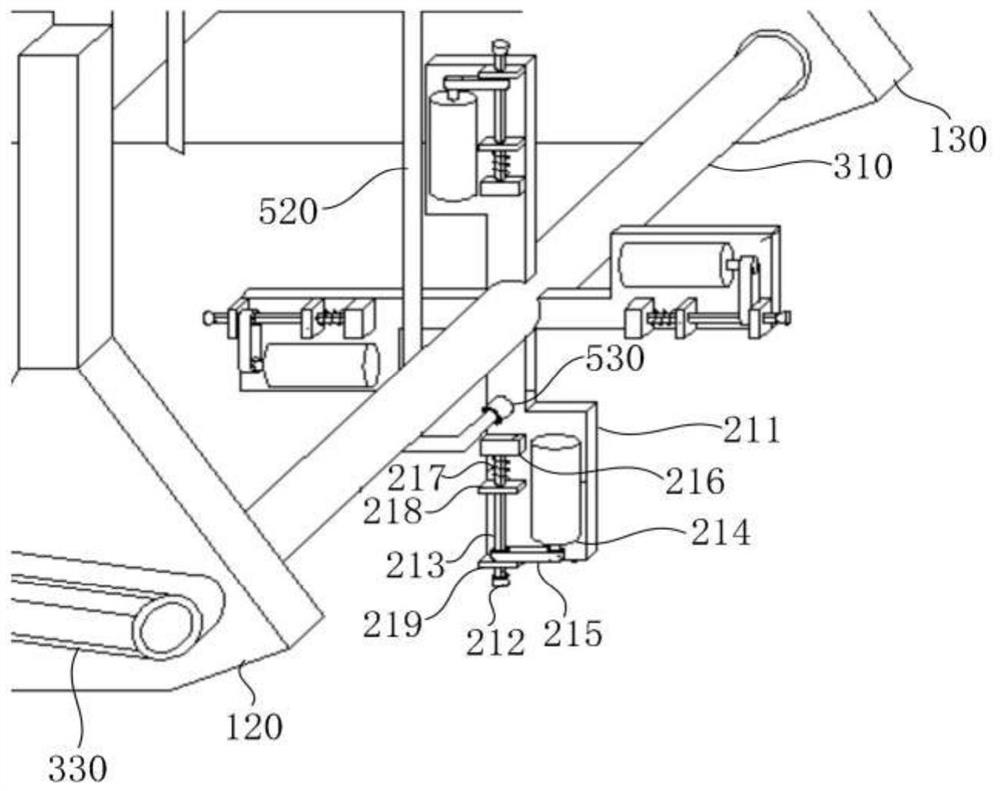

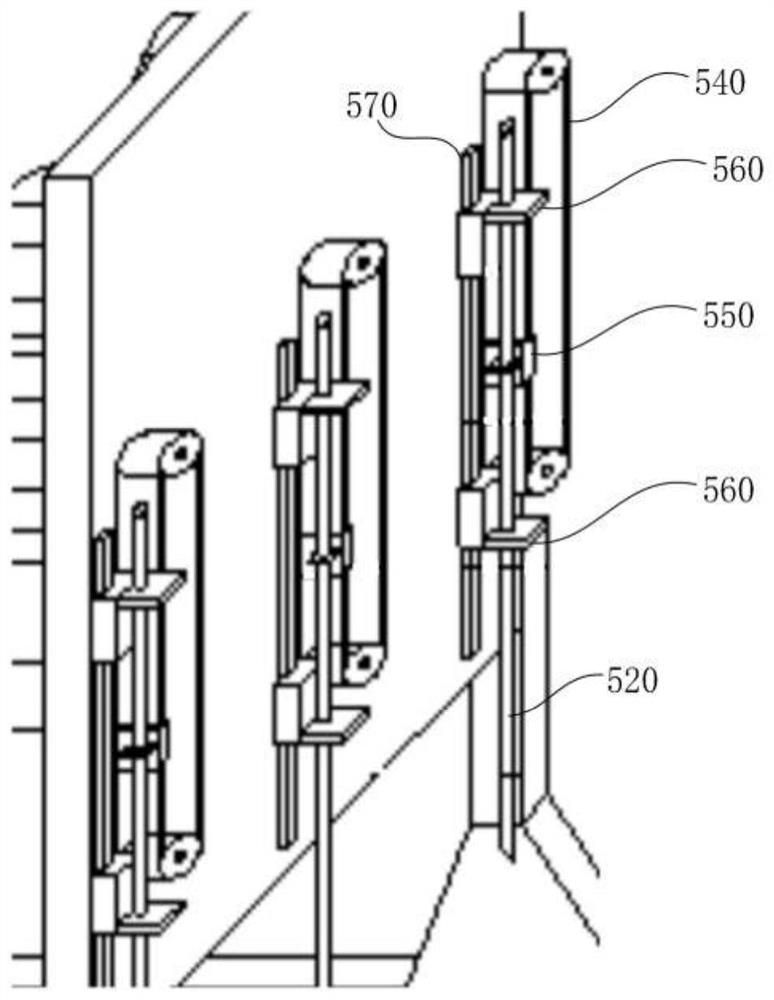

Reinforcing piece double-head mounting device for flexible printed circuit board

InactiveCN104780706AImprove placement accuracyIncrease placement speedCircuit bendability/stretchabilityPrinted circuit manufacturePrinted circuit boardComputer engineering

The invention discloses a reinforcing piece double-head mounting device for a flexible printed circuit board. The reinforcing piece double-head mounting device comprises a worktable, a cross beam transversely arranged on the worktable, a sliding seat arranged below one end of the cross beam in a manner of being perpendicular to the cross beam and used for fixing the flexible printed circuit board, and two mounting subsystems symmetrically arranged on the two sides of the cross beam, wherein each mounting subsystem comprises a feeding device and a mounting device; the mounting device comprises an image recognition device, a controller and a mounting head; the mounting head obtains a reinforcing piece to be mounted from the feeding device; the image recognition device collects image information of the reinforcing piece and the flexible printed circuit board; the controller is used for recognizing the image information collected by the image recognition device and controlling the mounting head to mount the reinforcing piece to a corresponding position of the flexible printed circuit board according to the image information. By adopting the reinforcing piece double-head mounting device, the reinforcing piece can be accurately mounted to the corresponding position of the flexible printed circuit board, the mounting speed is greatly improved, and the efficiency is improved.

Owner:宁波军鸽防务科技有限公司 +1

Paster apparatus of battery pole ear

InactiveCN101442110AIncrease placement speedReduce labor intensityCell component detailsMechanical engineering

The invention discloses a patching device for battery tabs, which comprises a conveyer belt and an upright column frame arranged above the conveyer belt, wherein a pair of material pressing rods is arranged above the conveyer belt on the inner side of two upright columns; the material pressing rods are connected with material pressing cylinders arranged on the two upright columns respectively; a pair of cutting-off shears is arranged above the material pressing rods; the cutting-off shears are connected with cutting-off cylinders arranged on the material pressing rods respectively; a pair of bent chucks is arranged above the cutting-off shears; the middle parts of the two bent chucks are hinged on a lifting table respectively; two clamping cylinders are arranged on the lifting table; the clamping cylinders are connected with the other ends of the bent chucks; a lifting cylinder is arranged on a beam; and the lower end of the lifting cylinder is connected with the lifting table. The device has the advantages that the device is fast and accurate to patch, can greatly raise patching speed of the battery tabs, is stable and reliable in product quality, and greatly reduces the labor intensity of workers.

Owner:徐聚才

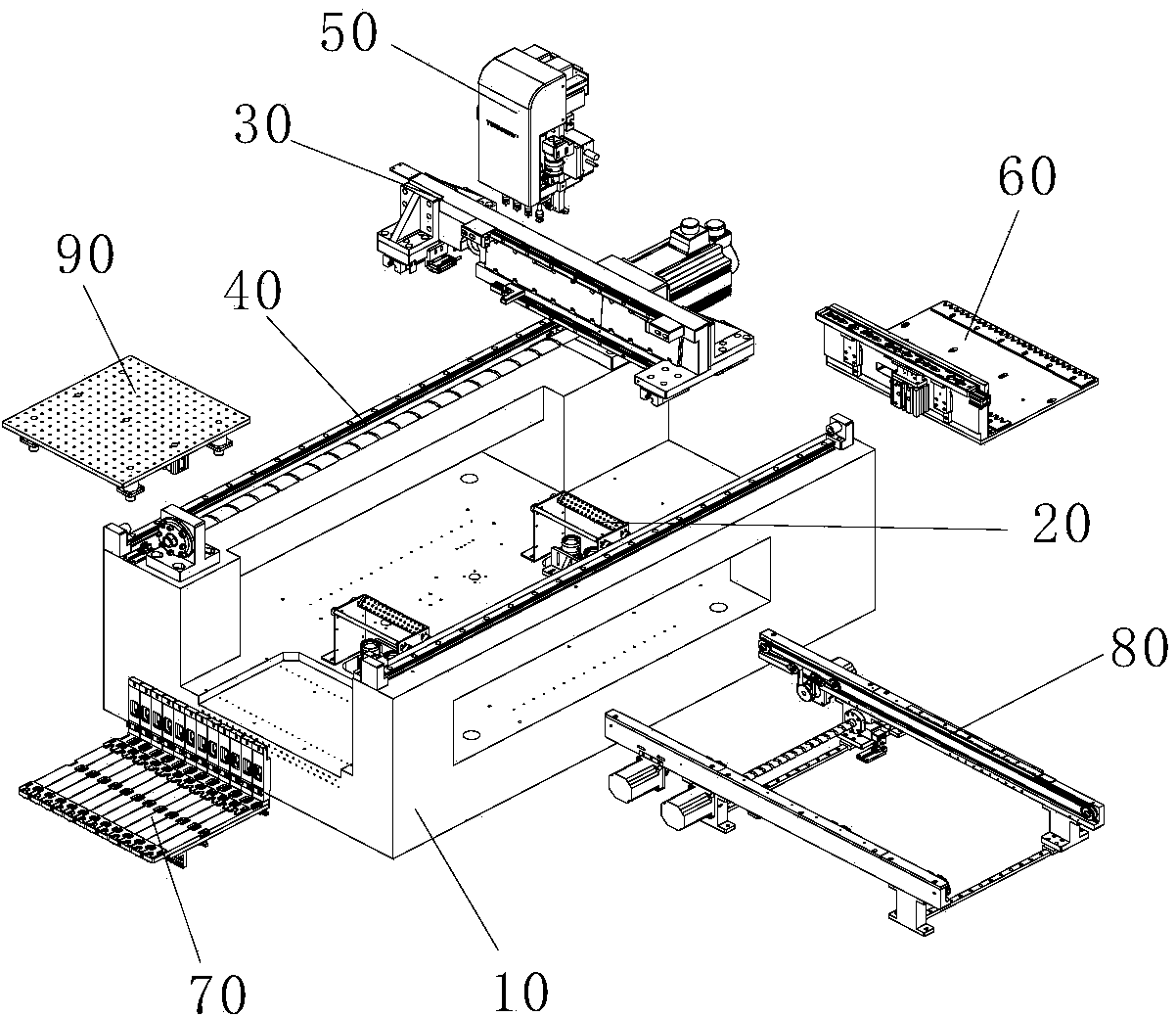

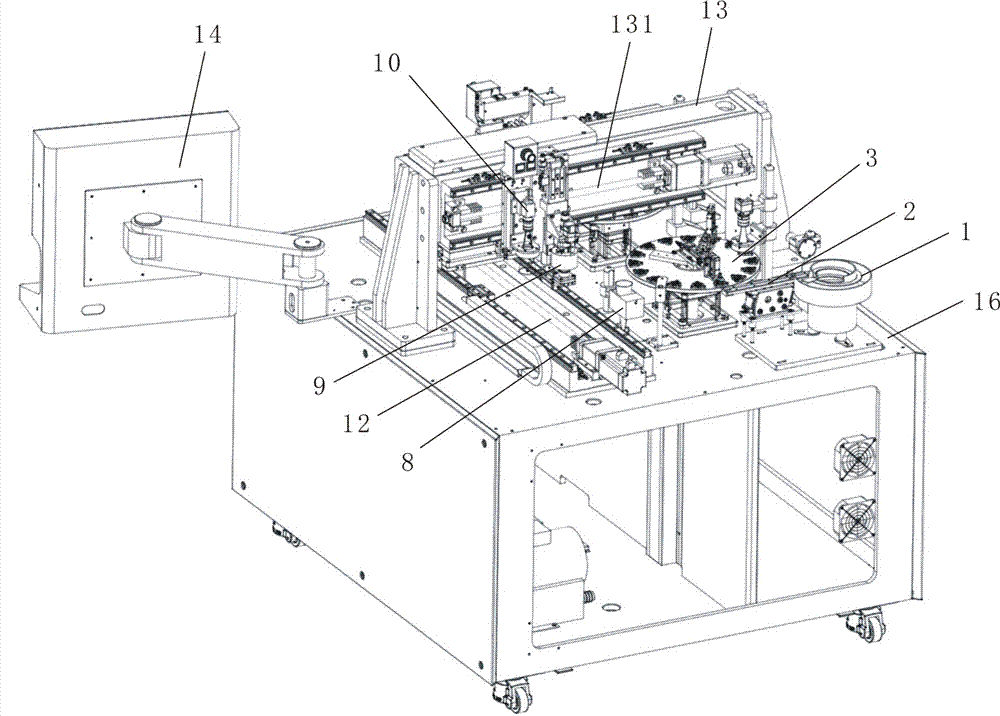

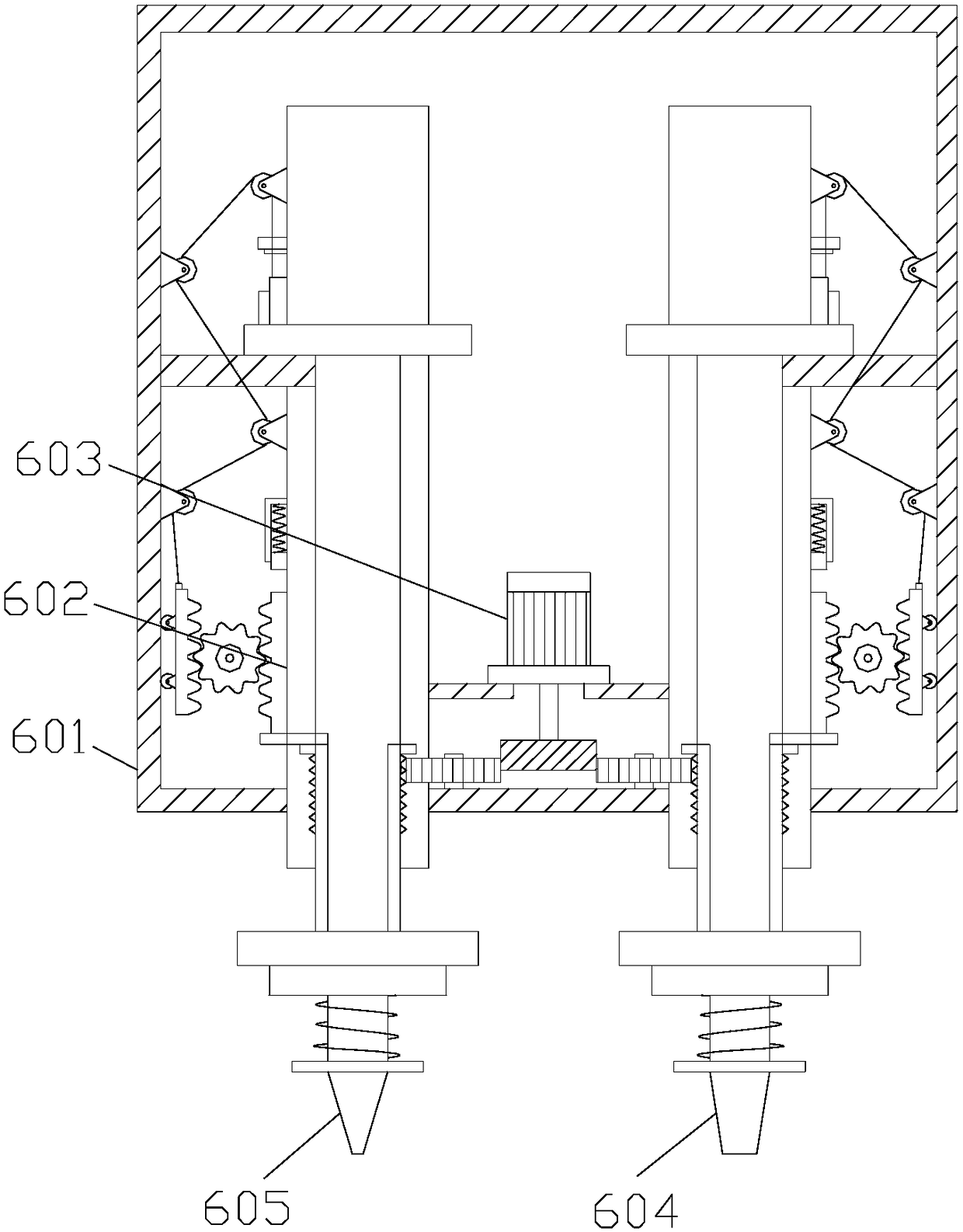

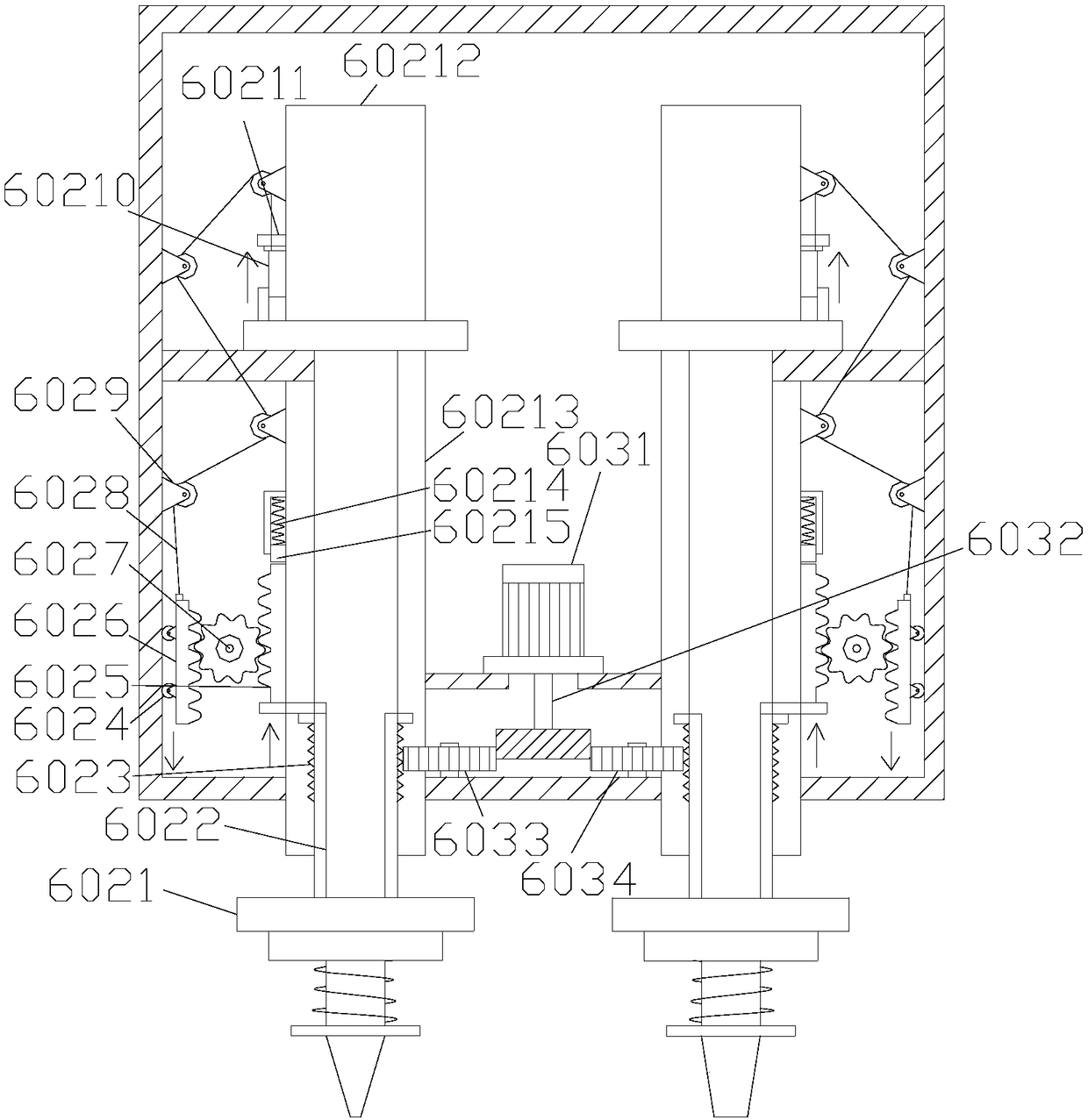

High-speed visual flexible circuit board placement machine

InactiveCN108391414AIncrease feed rateIncrease placement speedPrinted circuit assemblingElectrical componentsFlexible circuitsEngineering

The invention discloses a high-speed visual flexible circuit board placement machine, which structurally comprises support legs, a placement machine, a longitudinal guide rail bracket, a transverse guide rail bracket, a transverse chain, a placement head, a longitudinal chain and a servo motor. In order to achieve working of a plurality of suction nozzles of the high-speed visual flexible circuitboard placement machine, to reduce the overall occupied space of equipment and to improve the product placement speed, the placement machine is provided with the placement head and the placement headsucks products by adopting a first suction nozzle and a second suction nozzle, so that the production efficiency is improved, the placement accuracy is ensured and the suction time of each product isshortened; a tray bouncing and clamping-type lifting mechanism is arranged in the placement machine and the overall occupied space of the equipment is reduced by using the tray bouncing and clamping-type lifting mechanism, so that the equipment can adapt to a placement position in a workshop; and the products are quickly pushed through a tray push mechanism, so that the product placement efficiency is improved, and the high-speed visual flexible circuit board placement machine is reasonable in design and practical.

Owner:梁瑞城

A Method of Creating Measurement Points Based on Online Measurement Technology

ActiveCN106202843BSimple and fast operationRealize adaptive point layoutGeometric CADSpecial data processing applicationsMeasurement pointComputer science

The invention discloses a measurement point creating method based on on-line measurement technology. The method comprises following steps: obtaining point, line or surface information on a to-be-machined model to obtain curve parameter field information; obtaining position information and detection direction of measuring points according to parameter field information and curve normal direction so that the multiple measurement points are created; and generating a measurement path during an on-line measuring system and compensating the path and optimizing. The measurement point creating method based on on-line measurement technology has following beneficial effects: working load is reduced; working efficiency is raised; a usage range is wide; the method supports a plurality of types and different kinds of models to create measuring points; participation of people is minimized and error rate is lowered.

Owner:西安精雕软件科技有限公司

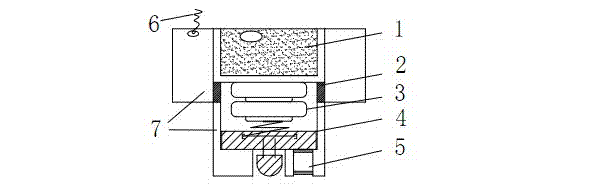

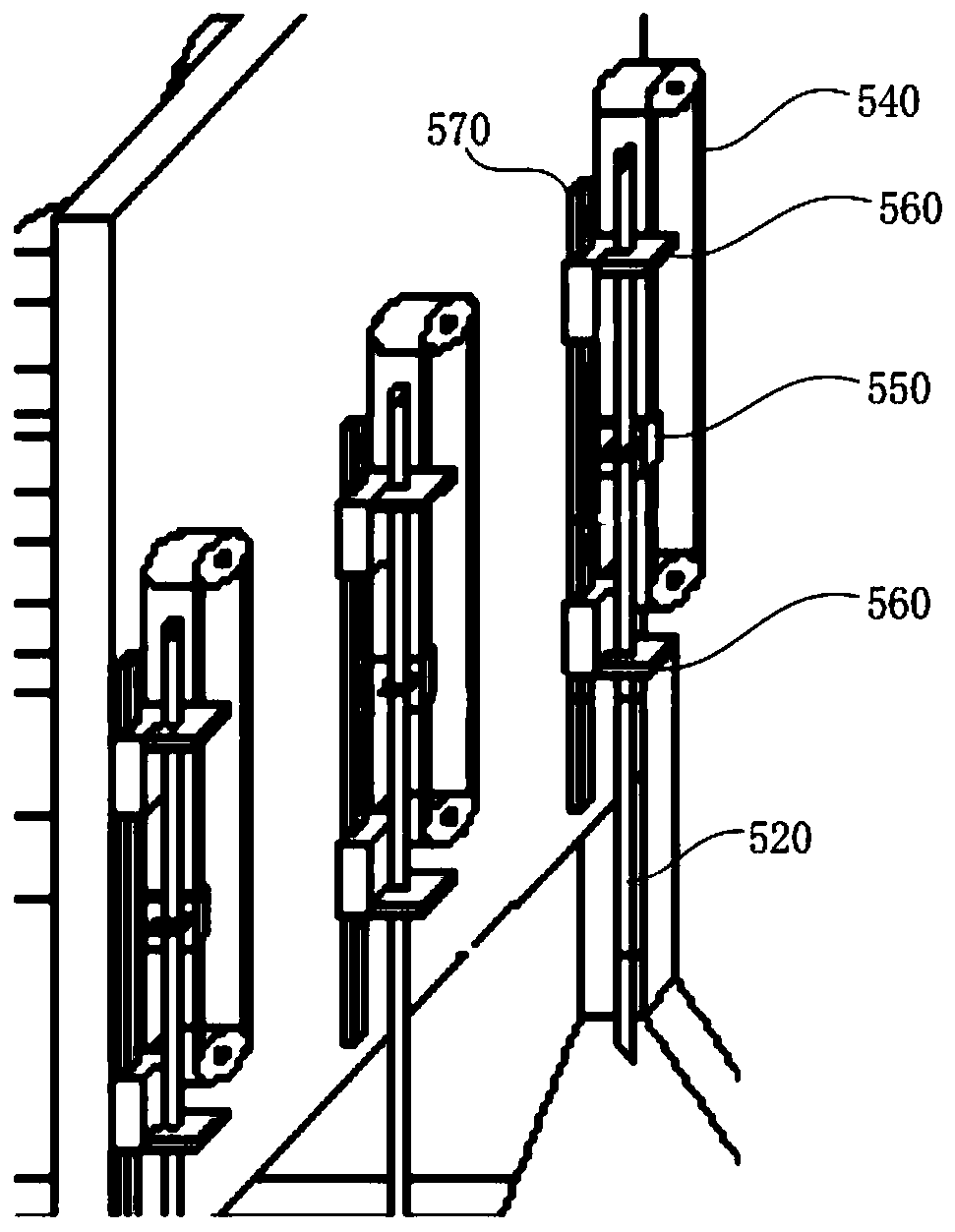

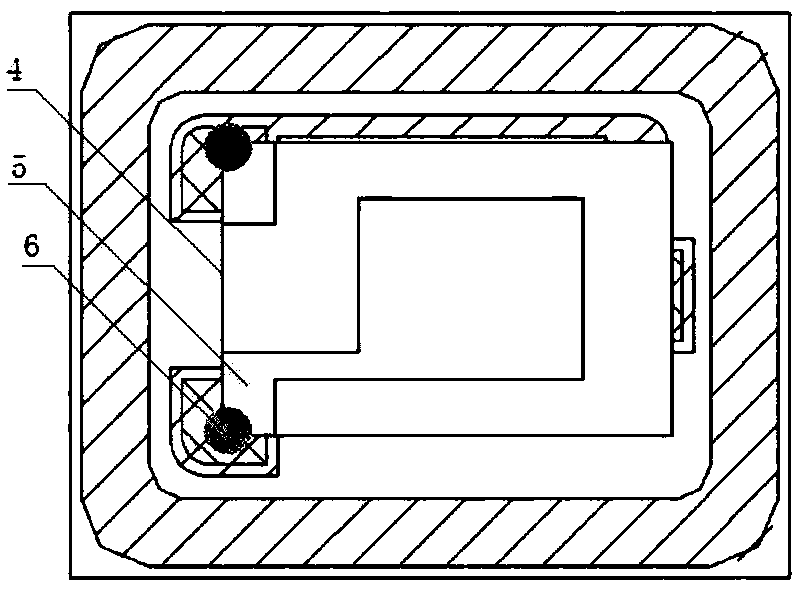

Double-row shaft rod chip mounting head

PendingCN111801004AIncrease placement speedLow costElectrical componentsElectric machineMiniaturization

The invention discloses a double-row shaft rod chip mounting head, which is composed of a chip mounting head main body structure, two rows of chip mounting mechanisms, Z-axis motor and synchronizers,R-axis motor and synchronizers, a MARK camera, a chip mounting head clamping device and a chip mounting head bracket, wherein the two rows of chip mounting mechanisms penetrate through a spline shaftmounting seat and are respectively mounted on two sides of a main mounting plate and a Z-axis guide plate; the Z-axis motors are the same as the mounting mechanisms in number, are respectively mountedon two sides of the main mounting plate, and control the chip mounting mechanisms to move up and down through synchronous wheels and synchronous belts; the R-axis motors are installed on the two sides of the spline shaft mounting seat respectively, and each R-axis motor controls the rotating movement of the multiple chip mounting mechanisms through the synchronous wheel and the synchronous belt.The double-row shaft rod chip mounting head has the beneficial effects that as the chip mounting mechanism of the double-row chip mounting head is doubled, the number of suction mounting elements in one stroke is doubled, and the overall chip mounting speed of the chip mounter is nearly doubled; and meanwhile, compared with a linear motor, the cost is lower, the whole machine is miniaturized due to the compact design, and the cost is also reduced.

Owner:广东木几智能装备有限公司

A modular high-speed placement head for LED placement

ActiveCN102711388BIncrease placement speedLow costPrinted circuit assemblingControl theoryHigh velocity

The invention relates to the field of chip mounters of electronic assembly, in particular to an economic high-speed mounting head technology for the chip mounters. The aim of the invention is to provide a mounting head with the characteristics of reasonable structural layout, simple transmission, small overall volume, light weight, high speed and low cost. A modular high-speed mounting head for LED (light emitting diode) mounting comprises a turntable rotating mechanism, a suction nozzle lifting mechanism, a suction nozzle rotating mechanism, an electrical protection and interface conversion device, and a suction nozzle. The turntable rotating mechanism comprises a mounting head fixing seat, a direct current servo motor used for providing driving force and arranged on the mounting head fixing seat, a first turntable for keeping linkage, a second turntable, a turntable connecting frame for connecting the first turntable and the output end of the direct current servo motor, and a turntable shaft.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

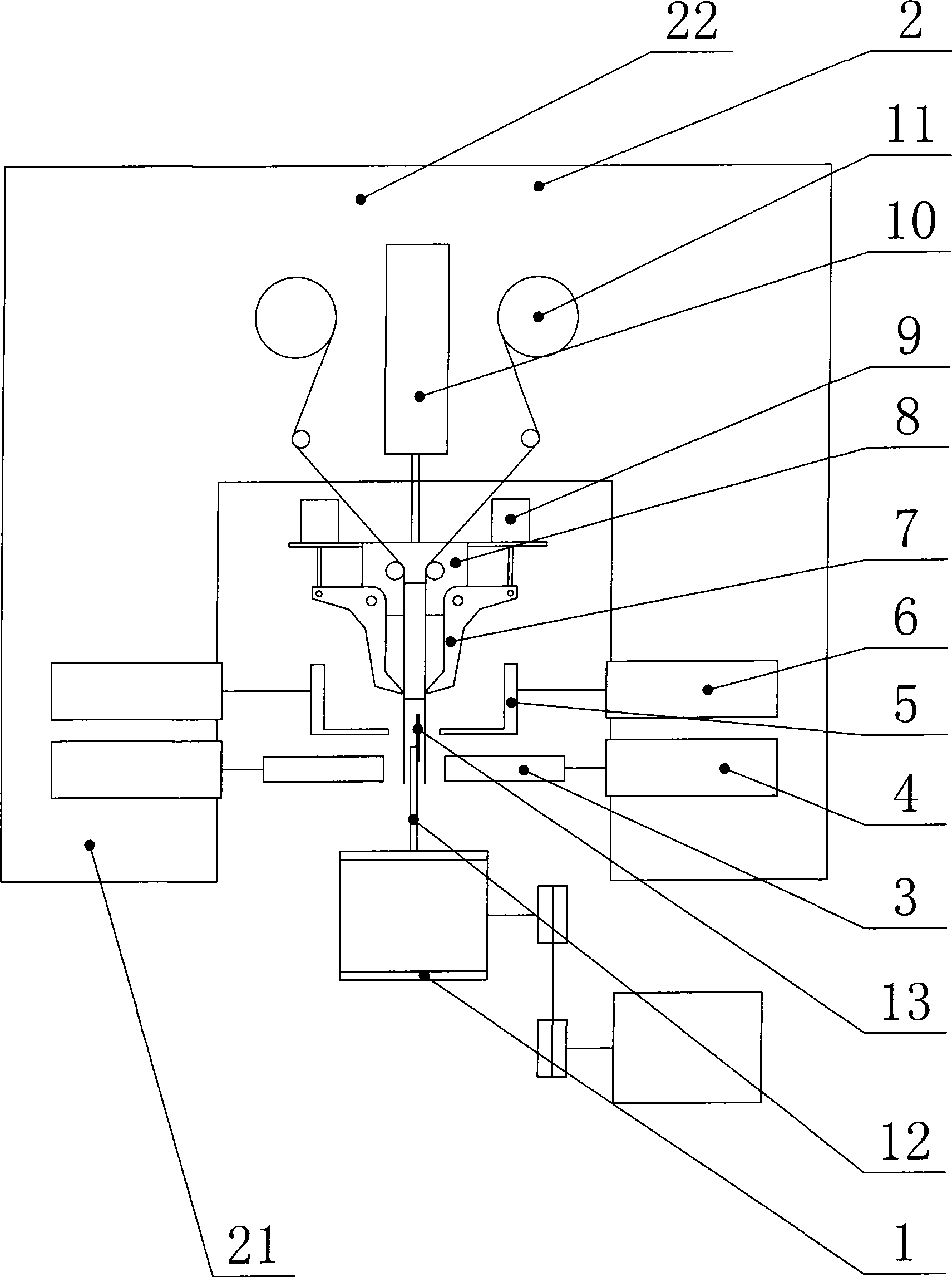

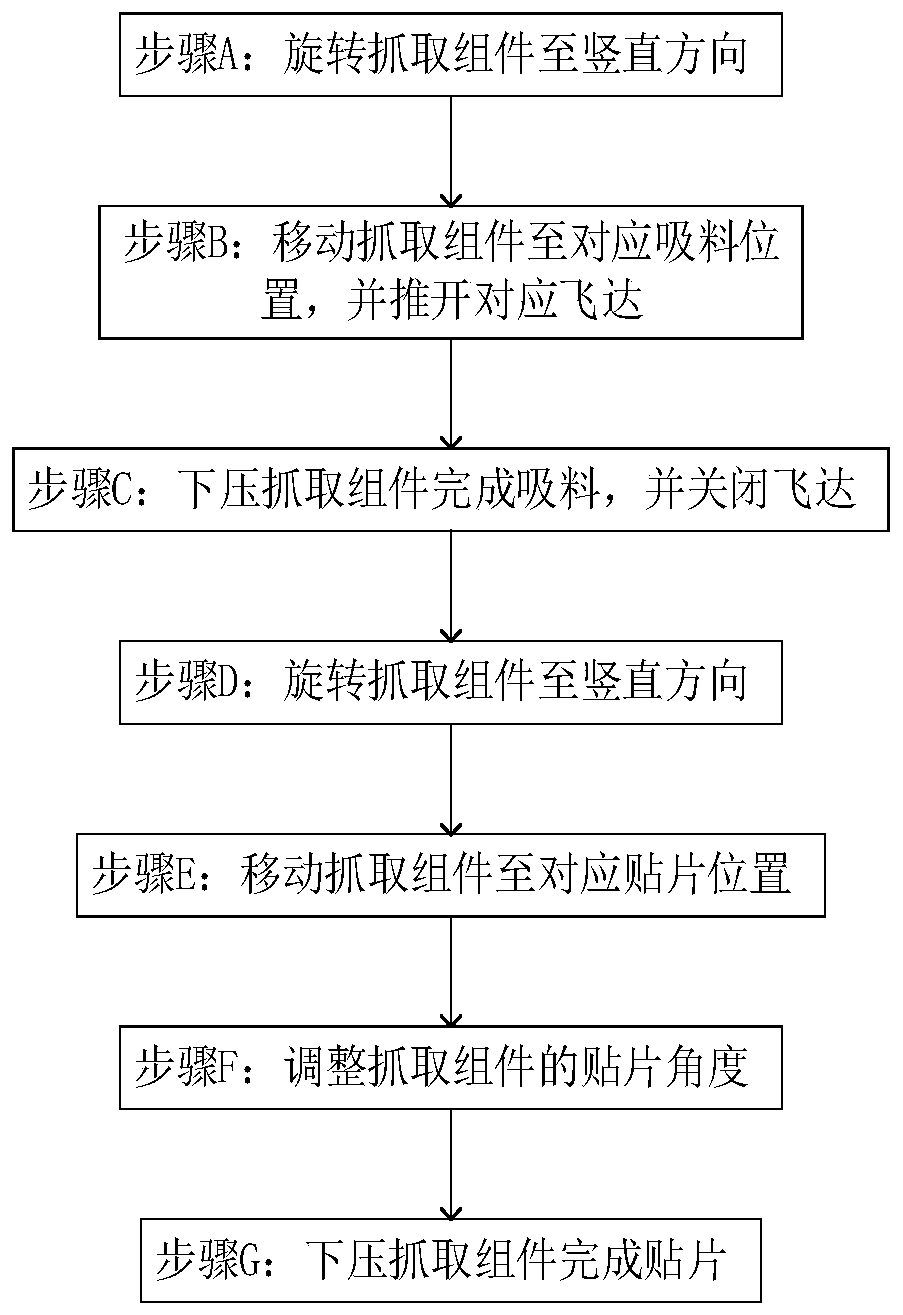

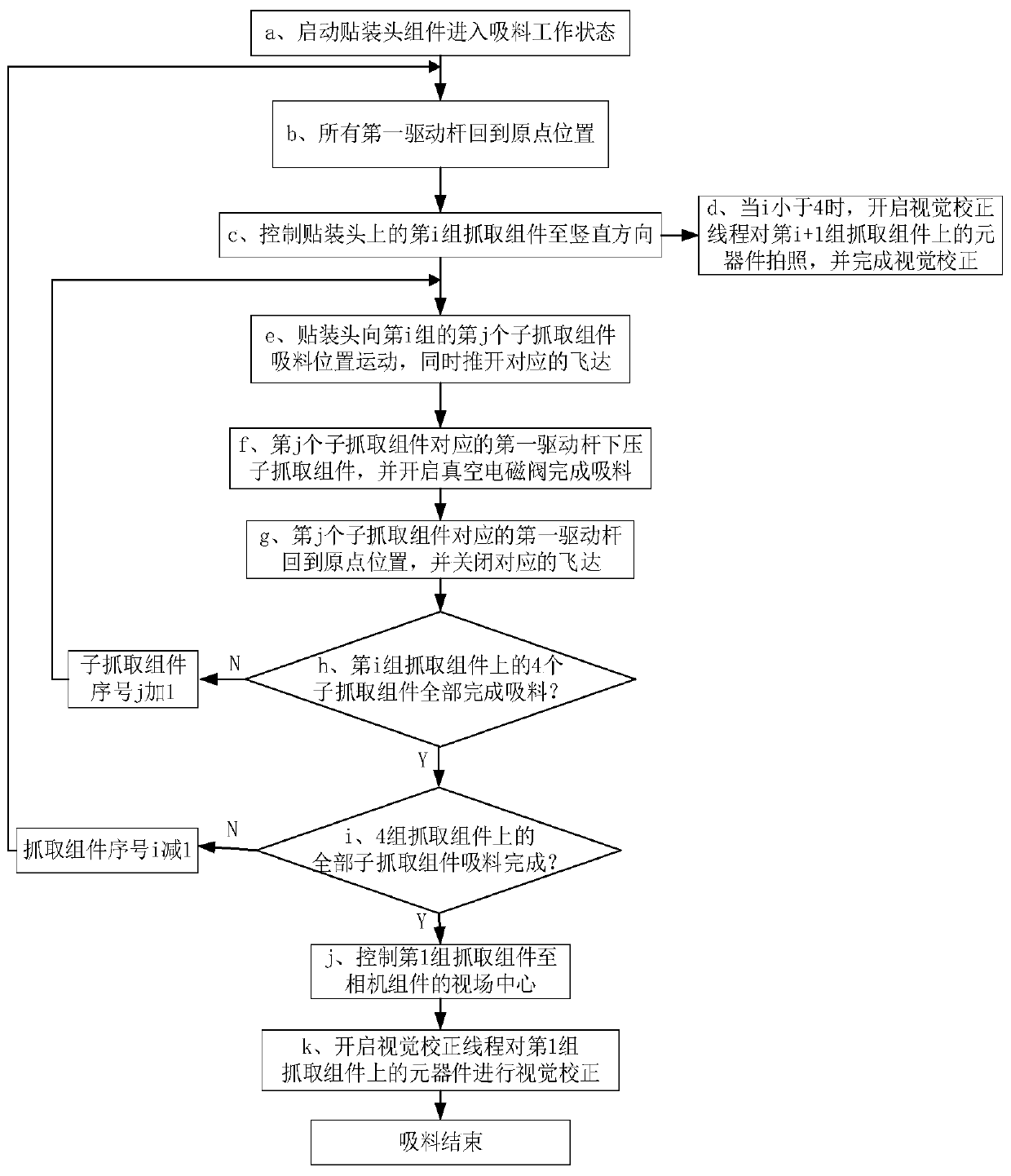

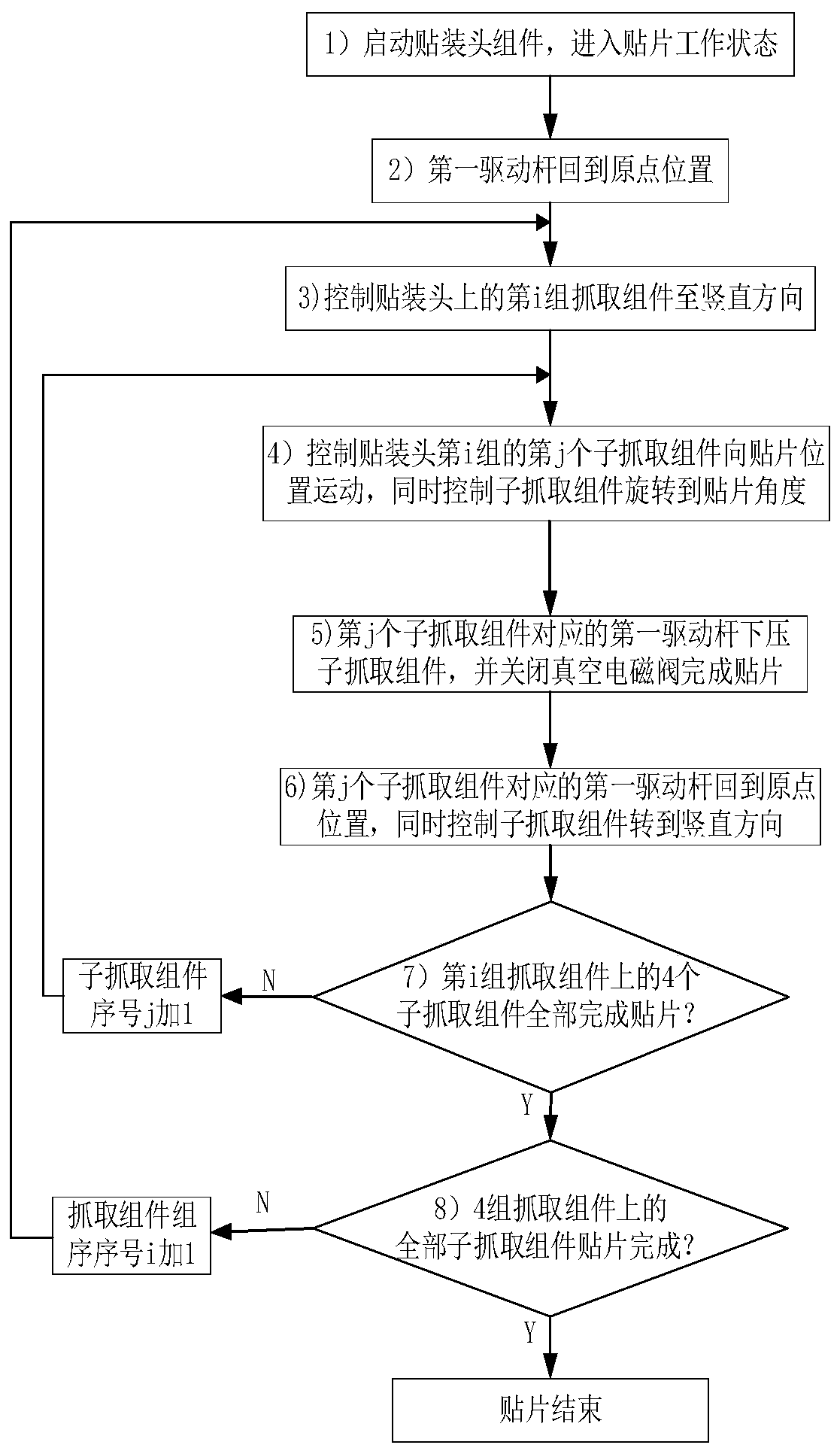

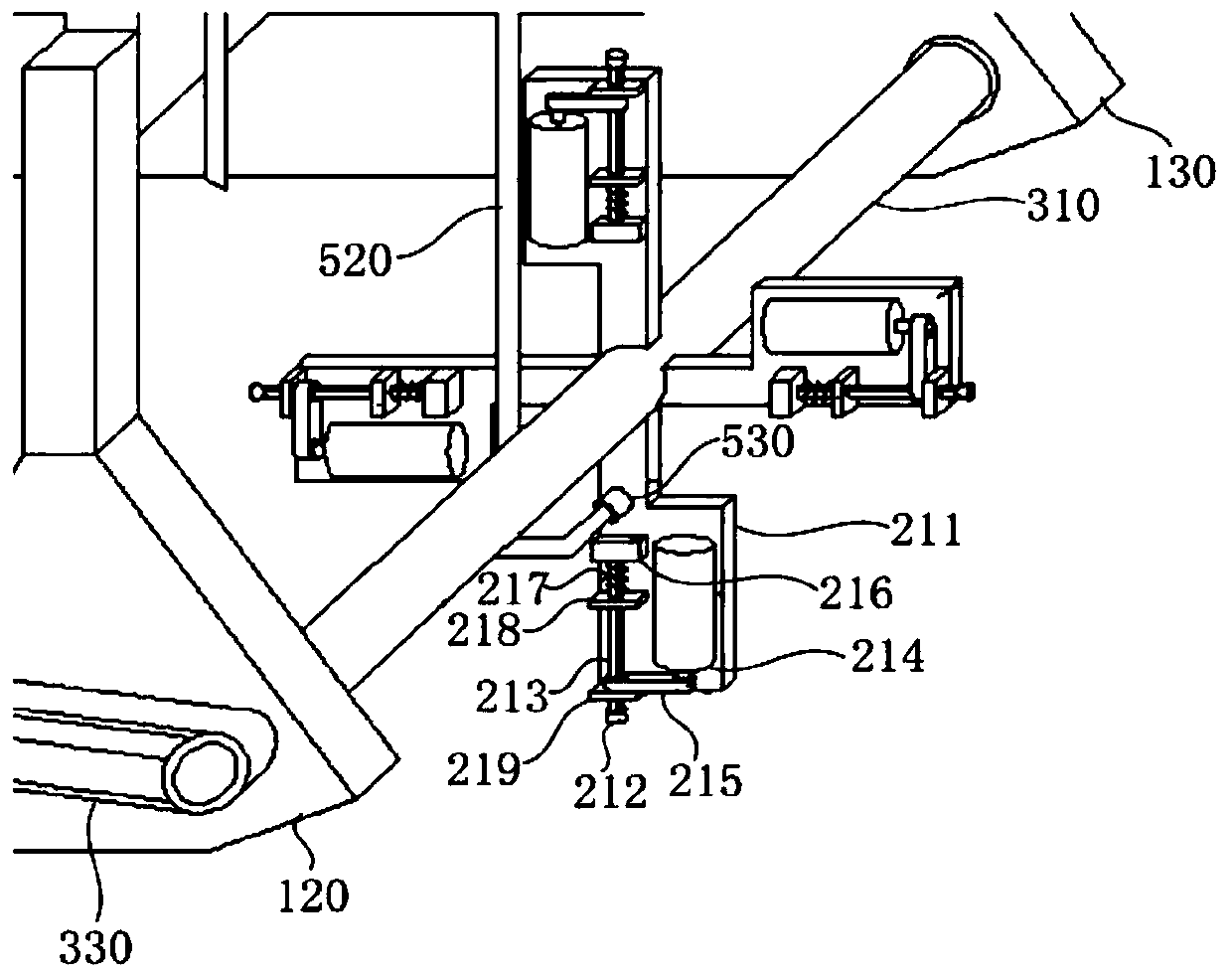

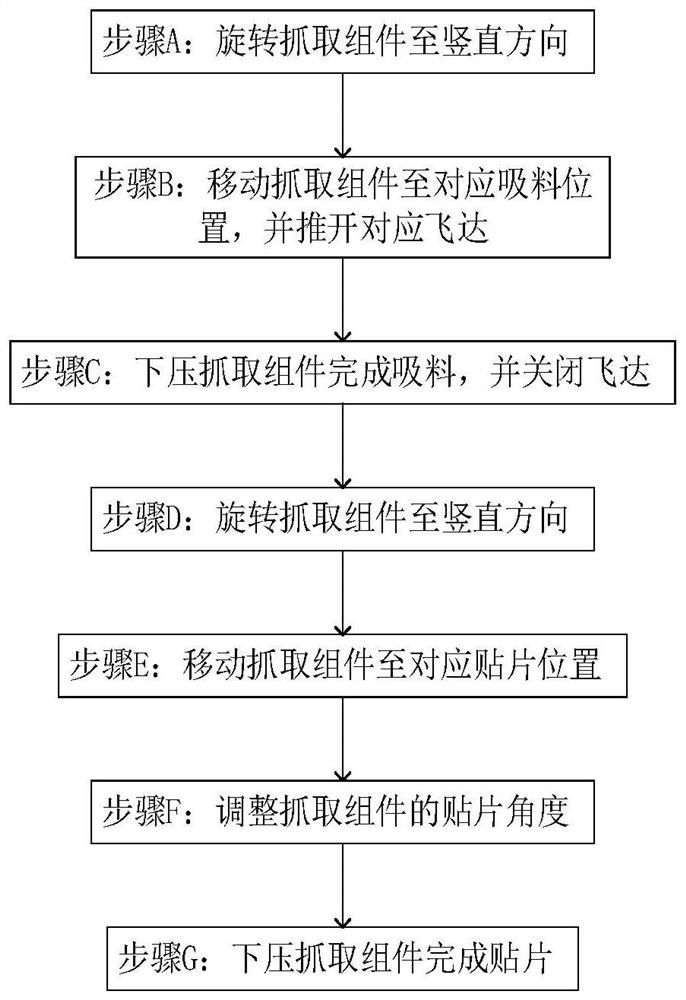

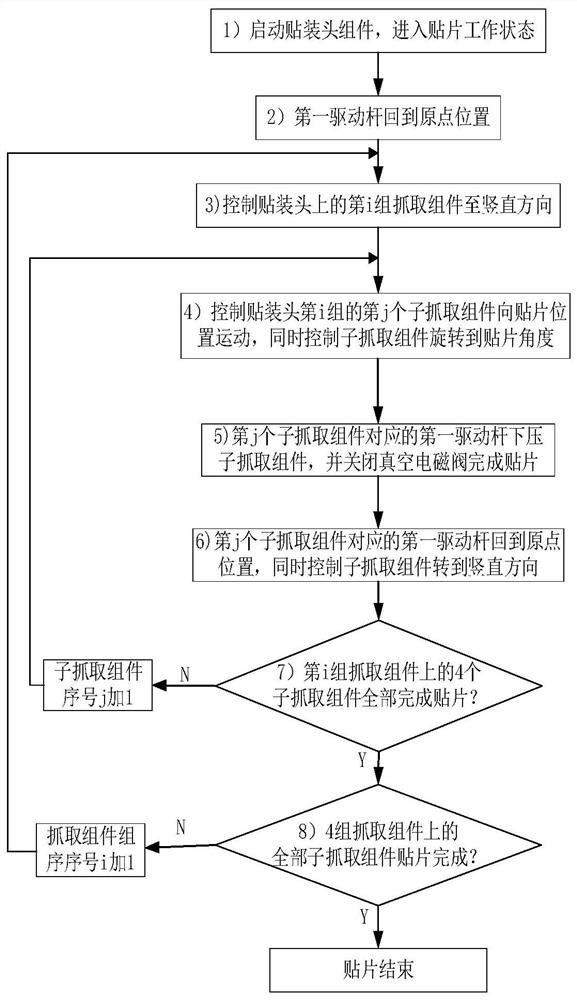

Ultra-high-speed surface mounting method and surface mounting head

ActiveCN111343847AImprove accuracyIncrease placement speedElectrical componentsComputer hardwareUltra high speed

The invention discloses an ultra-high-speed chip mounting method and a chip mounting head. The chip mounting head comprises a grabbing assembly. The chip mounting method comprises the following steps:step A, rotating the grabbing assembly to a vertical direction; b, the grabbing assemblies are moved to the corresponding material suction positions, and the corresponding feeders are pushed away; c,the grabbing assembly is pressed downwards to complete material suction, and the feeder is closed; d, the grabbing assembly is rotated to the vertical direction; e, the grabbing assembly is moved tothe corresponding patch position; f, the chip mounting angle of the grabbing assembly is adjusted; and G, the grabbing assembly is pressed down to complete chip mounting. The chip mounting method is simple in step, the chip mounting angle of the grabbing assembly can be adjusted, the chip mounting accuracy is improved, and the chip mounting speed of equipment such as a chip mounter is greatly increased.

Owner:方强

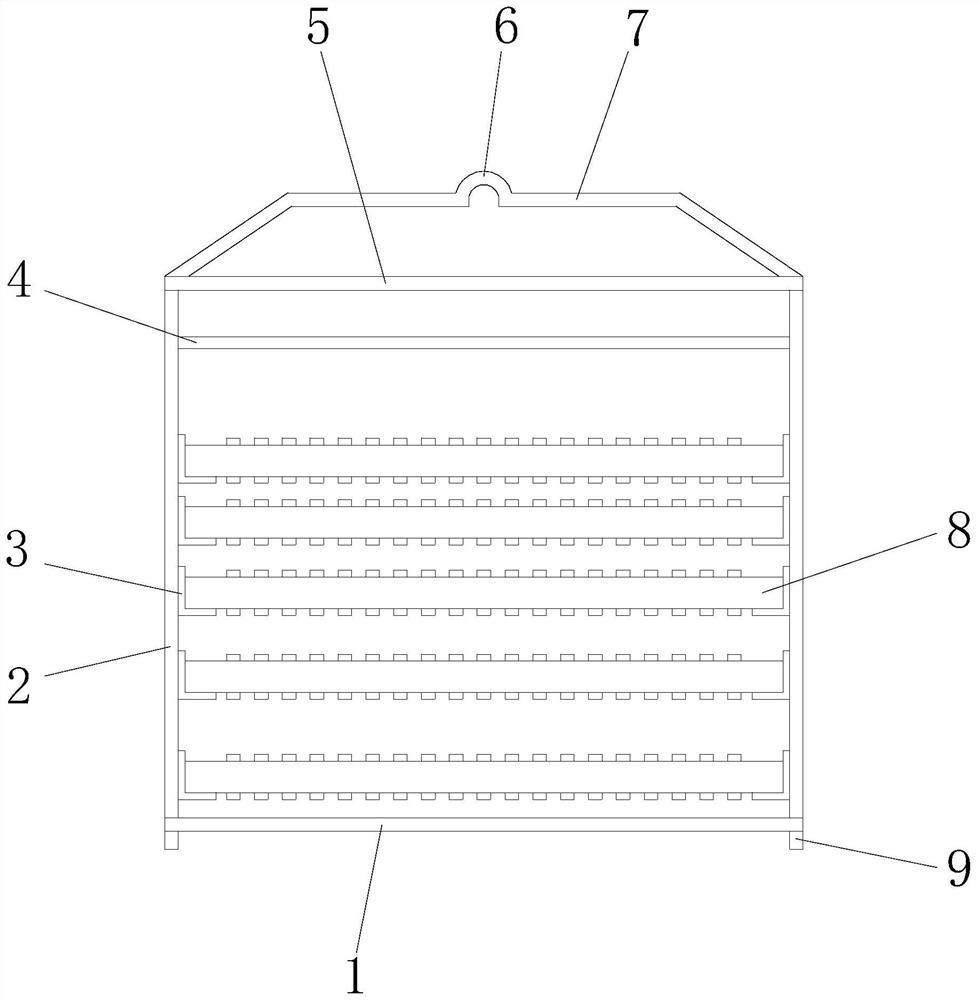

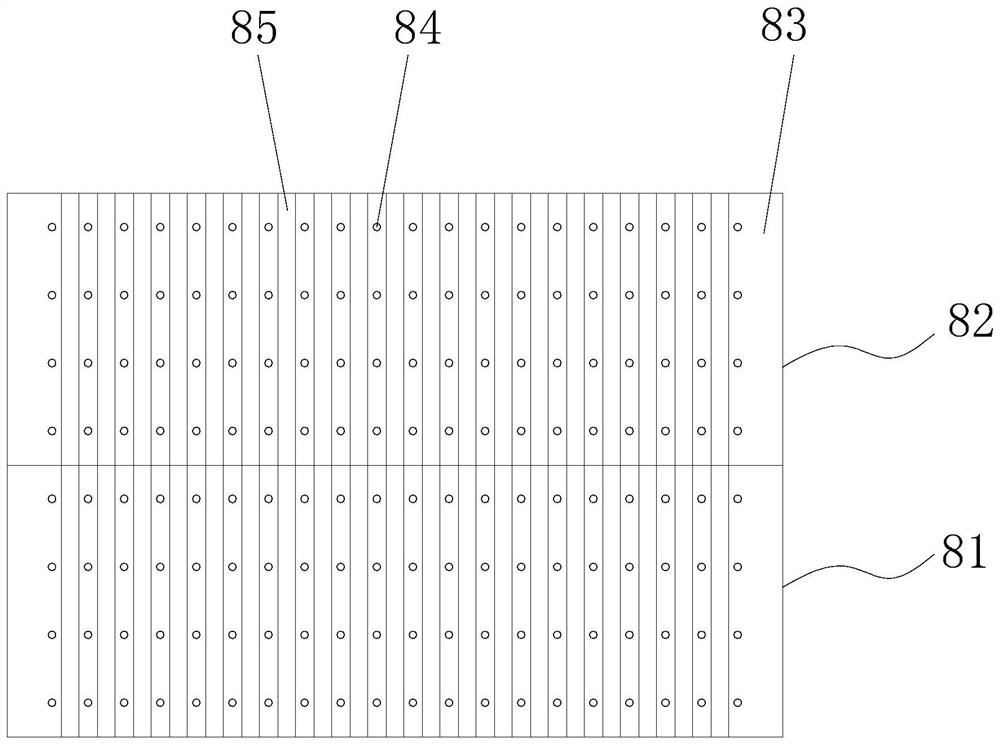

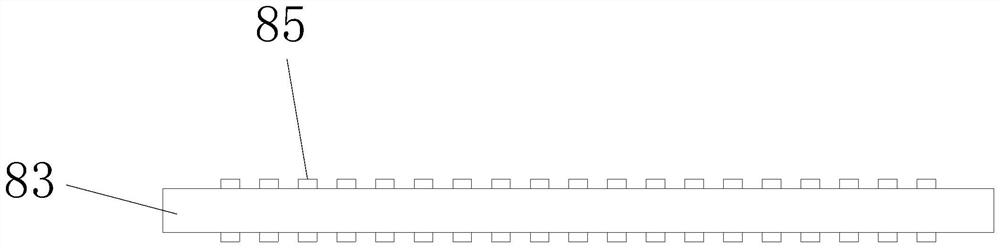

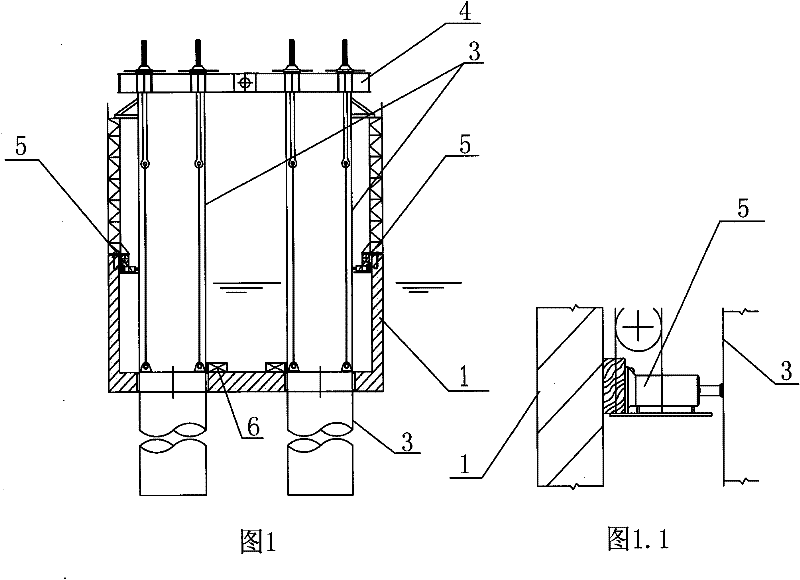

Whole plate die attach device and method during production of surface mount type quartz-crystal resonator

ActiveCN106067775AShorten the timeIncrease productionImpedence networksQuartz crystal resonatorSurface mounting

The invention belongs to the field of electronic components, and particularly relates to a whole plate die attach device and a method thereof during the production of a surface mount type quartz-crystal resonator. The whole plate die attach device comprises a fixing device, an adsorption device located in the fixing device, a moving device detachably connected with the fixing device, and whole plate wafers arranged on the moving device and configured to be attached to a substrate whole plate. The whole plate wafers are composed of a plurality of wafers. The adsorption device is in contact with the whole plate wafers arranged on the moving device. According to the technical scheme of the invention, the whole plate die attach method comprises the steps of integrally moving the plurality of wafers to form the whole plate wafers, and providing a single substrate corresponding to each wafer of the whole plate wafers right below the wafer. The wafers are absorbed and clamped integrally by a film-coating fixture and then are integrally placed on the substrate whole plate after the dispensing process. Therefore, the wafer placement time is shortened and the wafer mounting speed is high. Meanwhile, the production efficiency is improved by hundreds of times, and the production capacity is expanded.

Owner:SICHUAN MDH TECH CO LTD

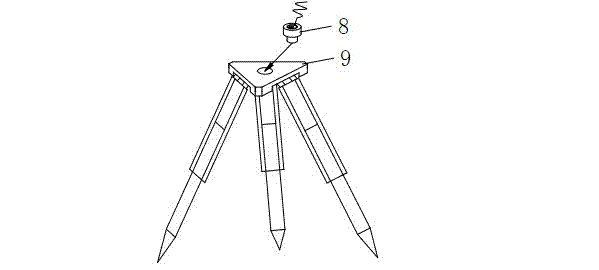

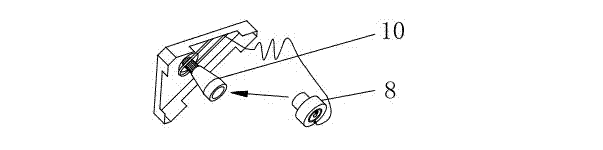

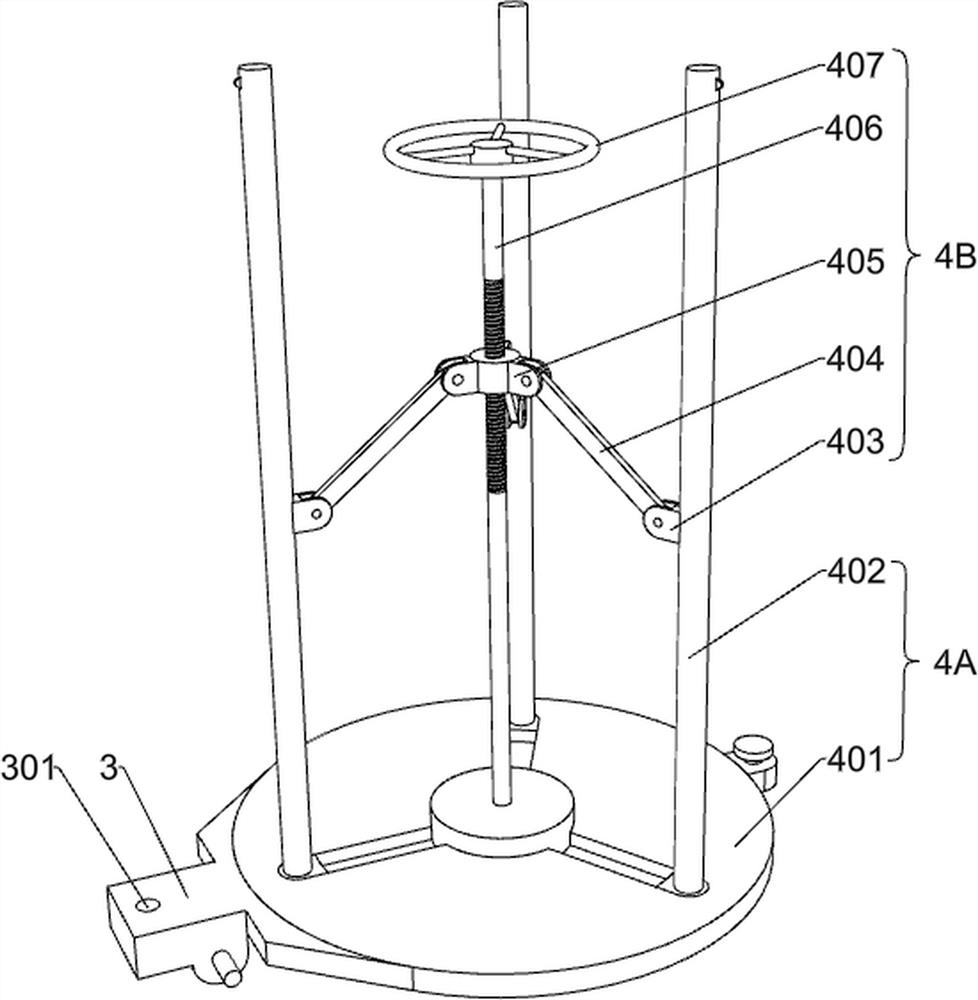

Tripod Mounting Adjustment Reference Unit

InactiveCN102297683AAvoid repeated adjustmentsAvoid inaccuraciesSurveying instrumentsTheodolitesTheodoliteEngineering

The tripod is placed to adjust the reference device, which is installed on the tripod and includes a casing with a stepped structure. A laser plummet is installed in the lower end of the casing. The laser plummet includes a laser diode, and the laser diode is connected to the power supply battery, respectively. The control button for controlling its switch is connected; a circular level is installed in the upper end of the shell, and the circular level is connected with the laser plummet. Beneficial effects of the present invention: (1) The device integrating the laser plummet and the circular level is applied to the theodolite tripod, which makes the centering and leveling process of the theodolite convenient and quick, and improves the efficiency of surveying and mapping. (2) The present invention uses plastic as the shell material, which is shock-proof and drop-proof. The whole device has simple structure, low cost, easy implementation and portability. It can not only increase the placement speed of the theodolite, but also improve the placement accuracy of the theodolite, and has broad prospects for popularization and application.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

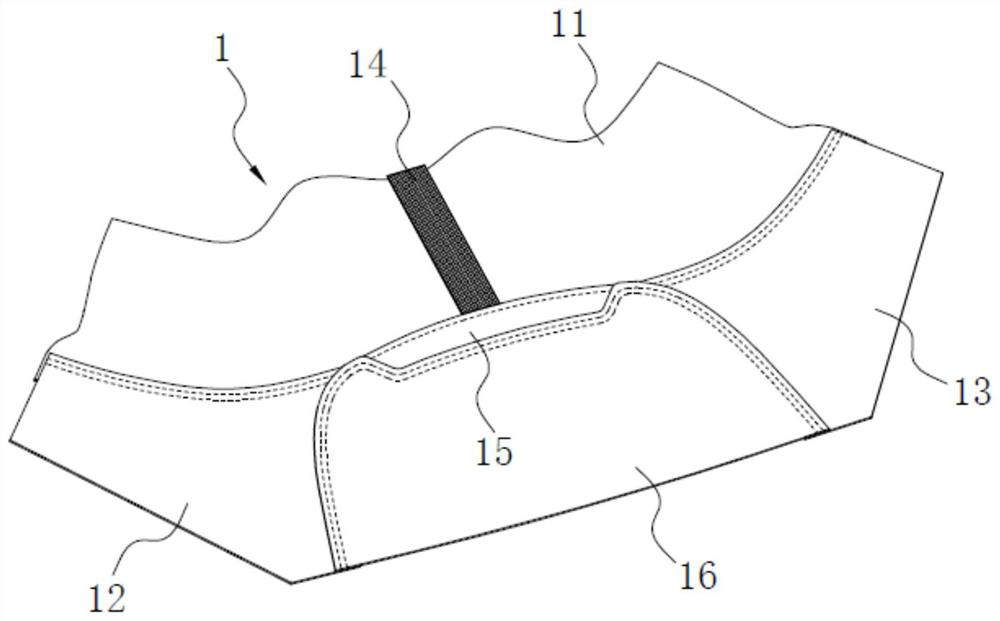

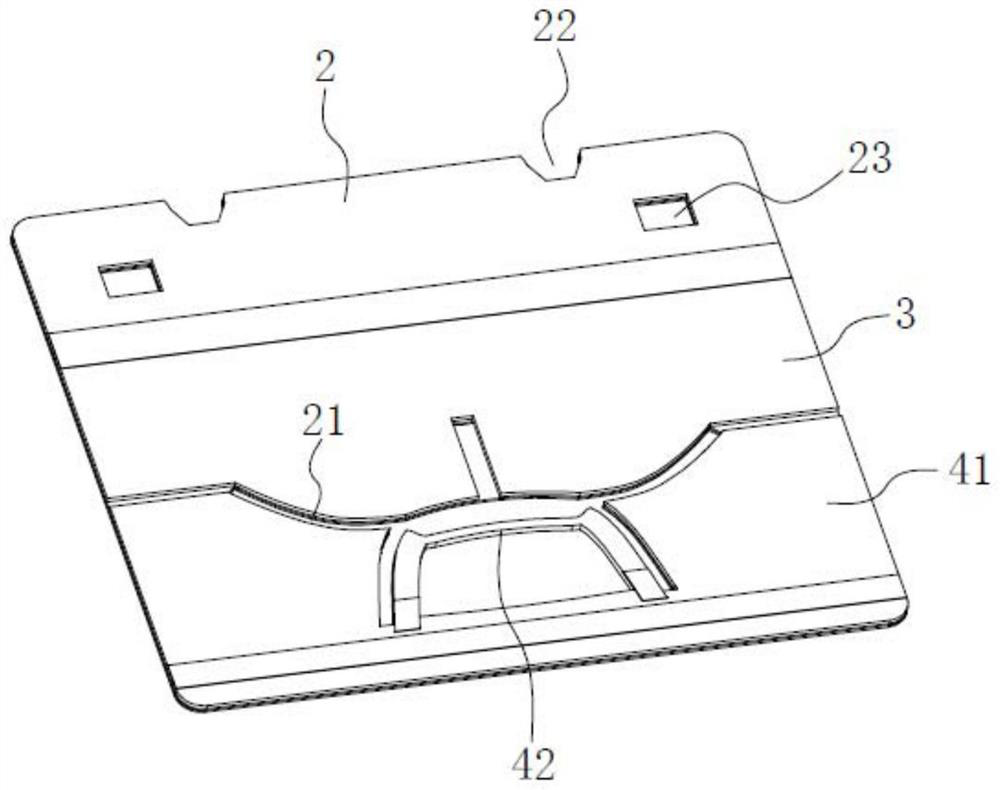

Safety shoe heel fabric assembly sewing template tool and sewing method

PendingCN112760833AReduce manufacturing costImprove finished product qualityWork-feeding meansMechanical engineeringIndustrial engineering

The invention discloses a safety shoe heel fabric assembly sewing template tool and a sewing method, and relates to the field of shoemaking. The template tool comprises a bottom plate assembly, a first pressing plate and a pressing plate assembly, wherein the first pressing plate and the pressing plate assembly cover the bottom plate assembly and can be opened; the middle of the bottom plate assembly is provided with a positioning groove used for containing a heel fabric assembly and a needle moving seam corresponding to a needle moving path; the positioning groove is internally provided with a neckline positioning area, a left-side-row positioning area, a right-side-row positioning area, a reflector positioning area and a heel positioning area; the first pressing plate covers the neckline positioning area; the pressing plate assembly comprises a second pressing plate and a heel pressing component; the second pressing plate covers the left-side-row positioning area and the right-side-row positioning area; and the heel pressing component covers the heel positioning area. According to the sewing method, the heel fabric assembly is sewn by means of the template tool. According to the sewing method, the manual participation in the needle moving sewing process can be reduced, the operation is simple and convenient, and the sewing efficiency of the heel fabric assembly and the consistency of finished products are greatly improved.

Owner:安徽希玛安全防护科技有限公司

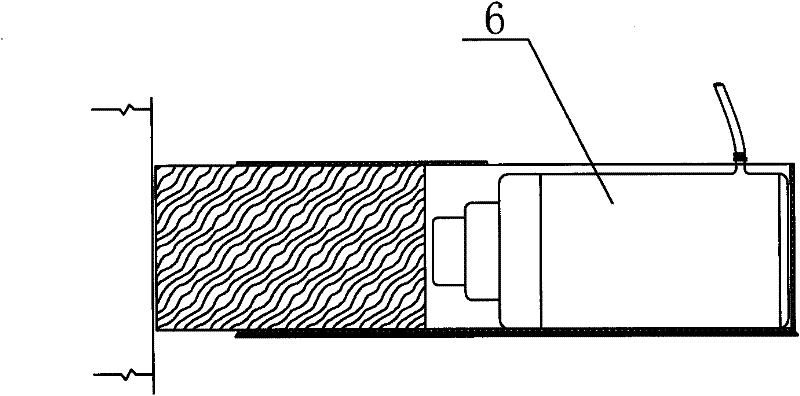

Automatic magnetic core placement machine

InactiveCN103496561BHigh precisionAvoid deformationJigging conveyorsConveyor partsEngineeringLaser cutting

The invention provides an automatic magnetic core placing machine. Laser cutting process and fine riveting process are utilized to manufacture a magnetic core placing disk, the manufactured magnetic core placing disk is high in accuracy, and the magnetic core placing disk is not prone to deforming and being damaged in high-temperature electroplating operation. The magnetic core placing disk can be recycled, so that the utilization rate is improved. The magnetic core placing disk is fixed on a Y-axis module, the Y-axis module can carry the magnetic core placing disk to move in the Y-axis direction, an X-axis module and a Z-axis fine adjustment and pneumatic device can carry a vacuum suction nozzle to move in the Y-axis direction and the Z-axis direction, and accordingly the vacuum suction nozzle can suck magnetic cores in any position and any direction to place the magnetic cores on the magnetic core placing disk. Full-automatic operation can be achieved through a self-programmed special material sucking and placing PLC procedure. Compared with an existing placing speed of 1,000 pieces per hour, the placing speed of the automatic magnetic core placing machine is about 8,000 pieces per hour. Thus, the placing speed is greatly improved.

Owner:深圳市智翔工业机器人科技有限公司

Paster apparatus of battery pole ear

InactiveCN101442110BIncrease placement speedReduce labor intensityCell component detailsEngineeringMechanical engineering

The invention discloses a patching device for battery tabs, which comprises a conveyer belt and an upright column frame arranged above the conveyer belt, wherein a pair of material pressing rods is arranged above the conveyer belt on the inner side of two upright columns; the material pressing rods are connected with material pressing cylinders arranged on the two upright columns respectively; a pair of cutting-off shears is arranged above the material pressing rods; the cutting-off shears are connected with cutting-off cylinders arranged on the material pressing rods respectively; a pair of bent chucks is arranged above the cutting-off shears; the middle parts of the two bent chucks are hinged on a lifting table respectively; two clamping cylinders are arranged on the lifting table; the clamping cylinders are connected with the other ends of the bent chucks; a lifting cylinder is arranged on a beam; and the lower end of the lifting cylinder is connected with the lifting table. The device has the advantages that the device is fast and accurate to patch, can greatly raise patching speed of the battery tabs, is stable and reliable in product quality, and greatly reduces the labor intensity of workers.

Owner:徐聚才

Method and a placement tool for the manufacture of a non-crimp fabric

ActiveUS8974623B2Improve performanceNo effectMechanical working/deformationConfectioneryEngineeringMechanical engineering

Owner:AIRBUS OPERATIONS GMBH

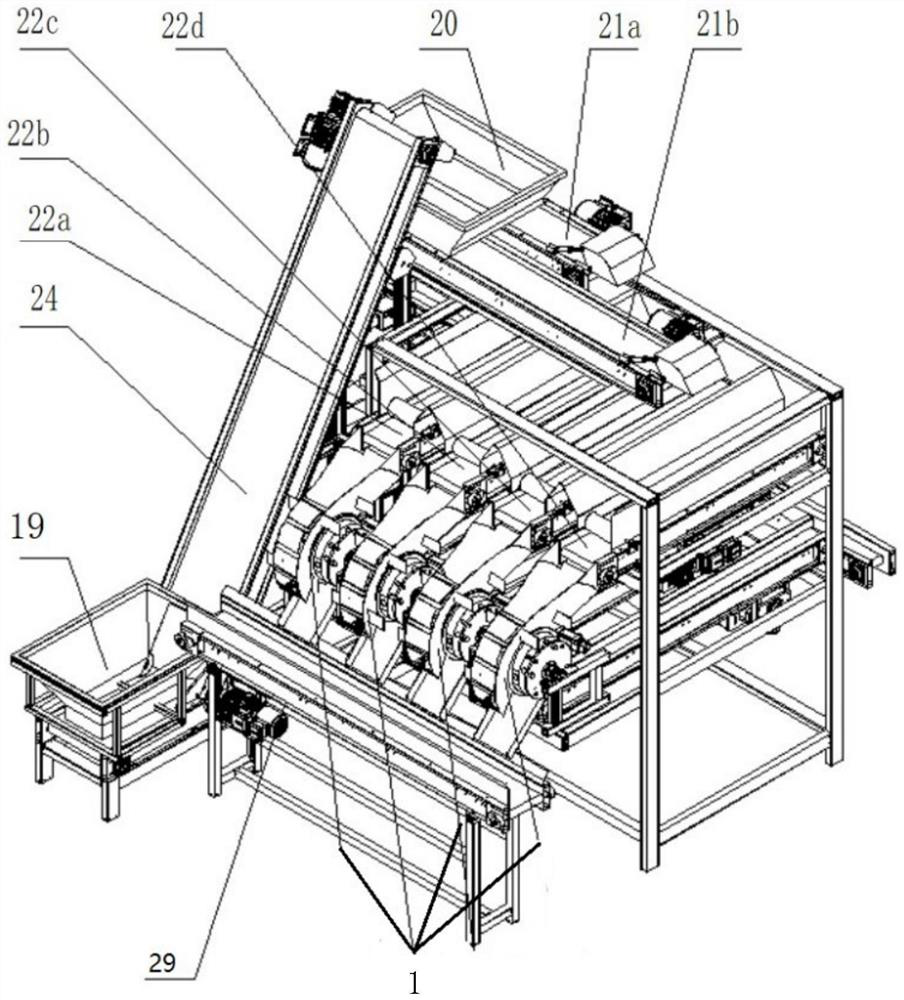

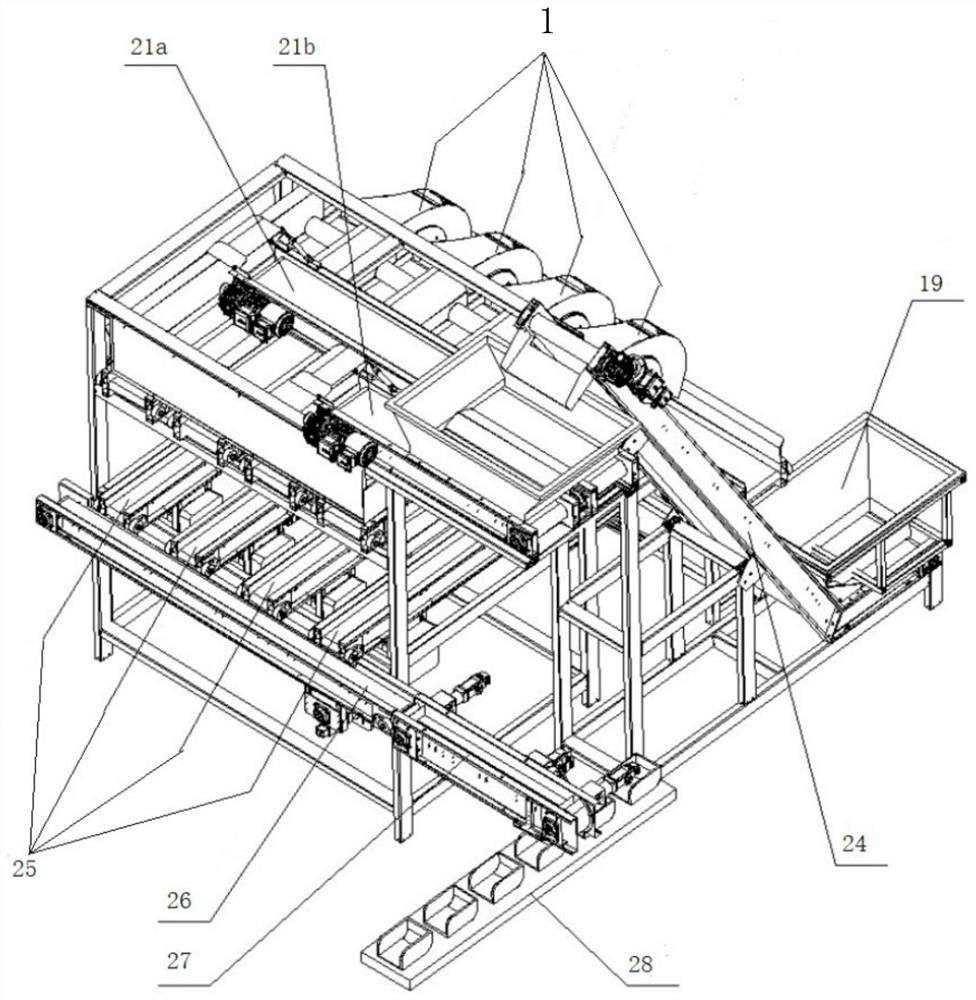

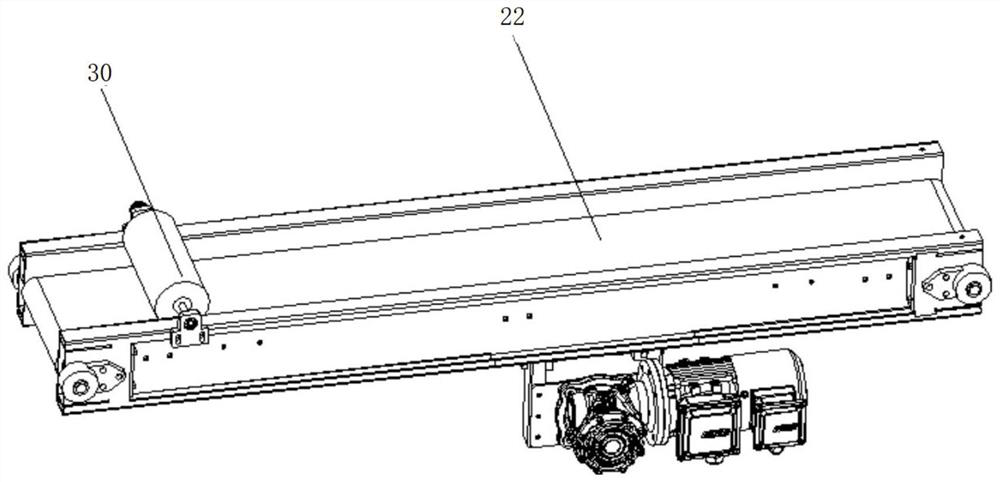

A multi-station material quantitative sorting and rapid material sorting device and material sorting method

ActiveCN113184269BTiling fastEasy to distribute evenly and orderlyPackaging automatic controlStructural engineeringMaterial distribution

The invention provides a multi-station material quantitative sorting fast material sorting device and a material sorting method, which relate to the technical field of material sorting and include an upper hopper in which a plurality of material bags are stored, and the upper hopper The right side is fixed with an upward-sloping climbing belt. A top silo is placed on the bottom of the climbing belt. The top silo is used to store material bags. Material belts, two adjacent material distribution belts are arranged in parallel; when the first pressing block of the present invention is pressed down, it will push the first pushing block to slide outward, so that the upright material bag falling on the turning base Push from the top of the material bag to turn the material bag on the overlapping belt. By turning the material bag over, the other side of the material bag is facing up on the overlapping material belt, which is more convenient for manual inspection and observation of the surface of the material bag, and improves the detection. efficiency and improve detection accuracy.

Owner:苏州凌创科技发展有限公司

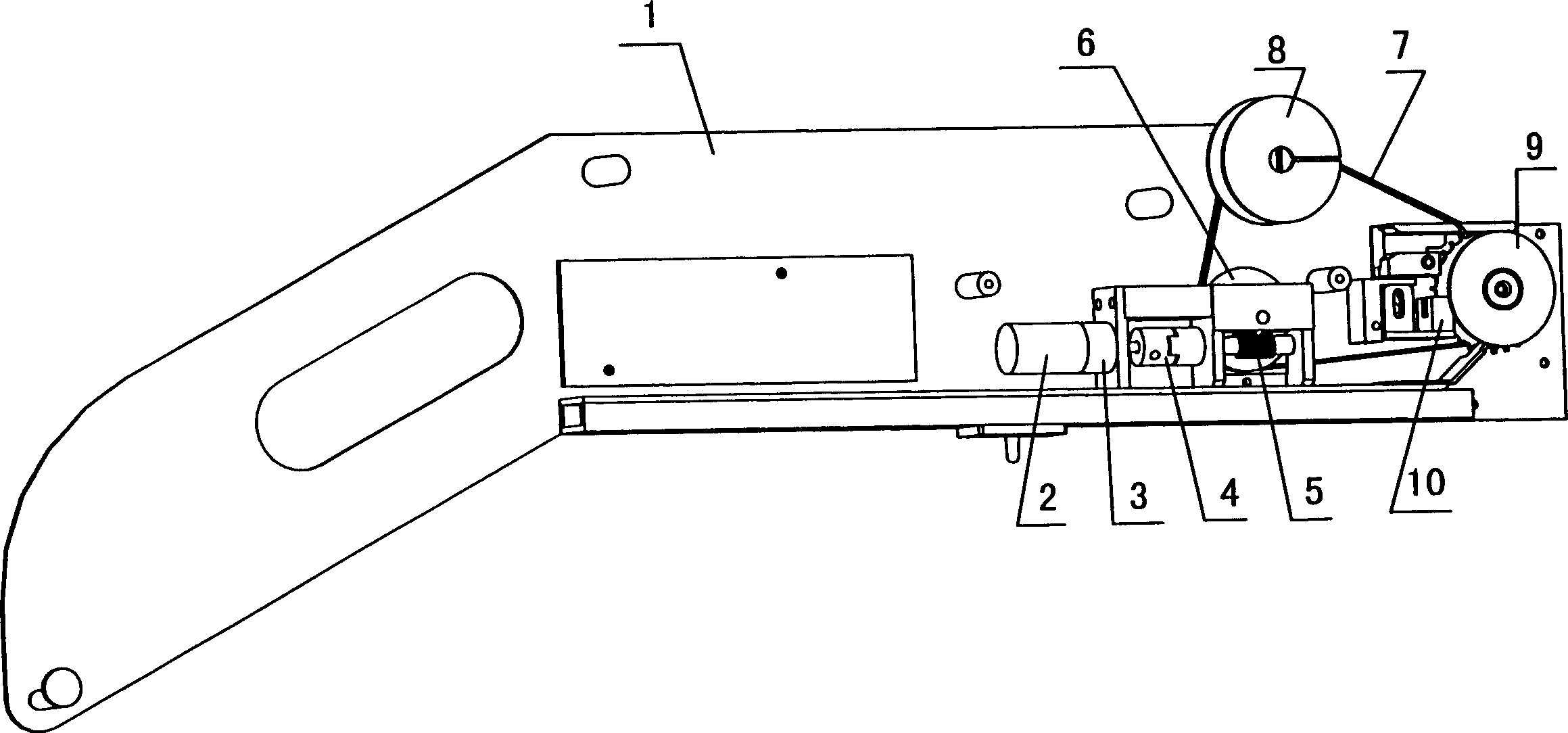

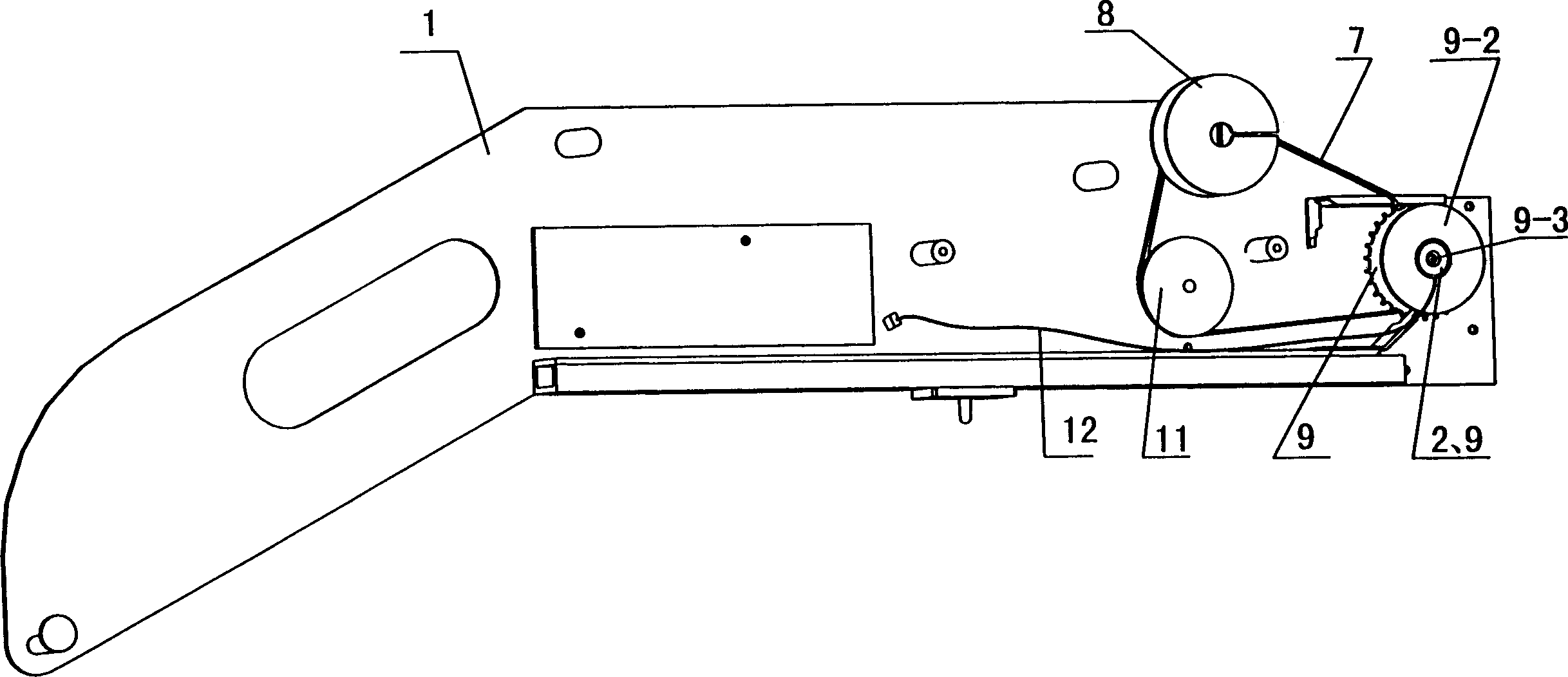

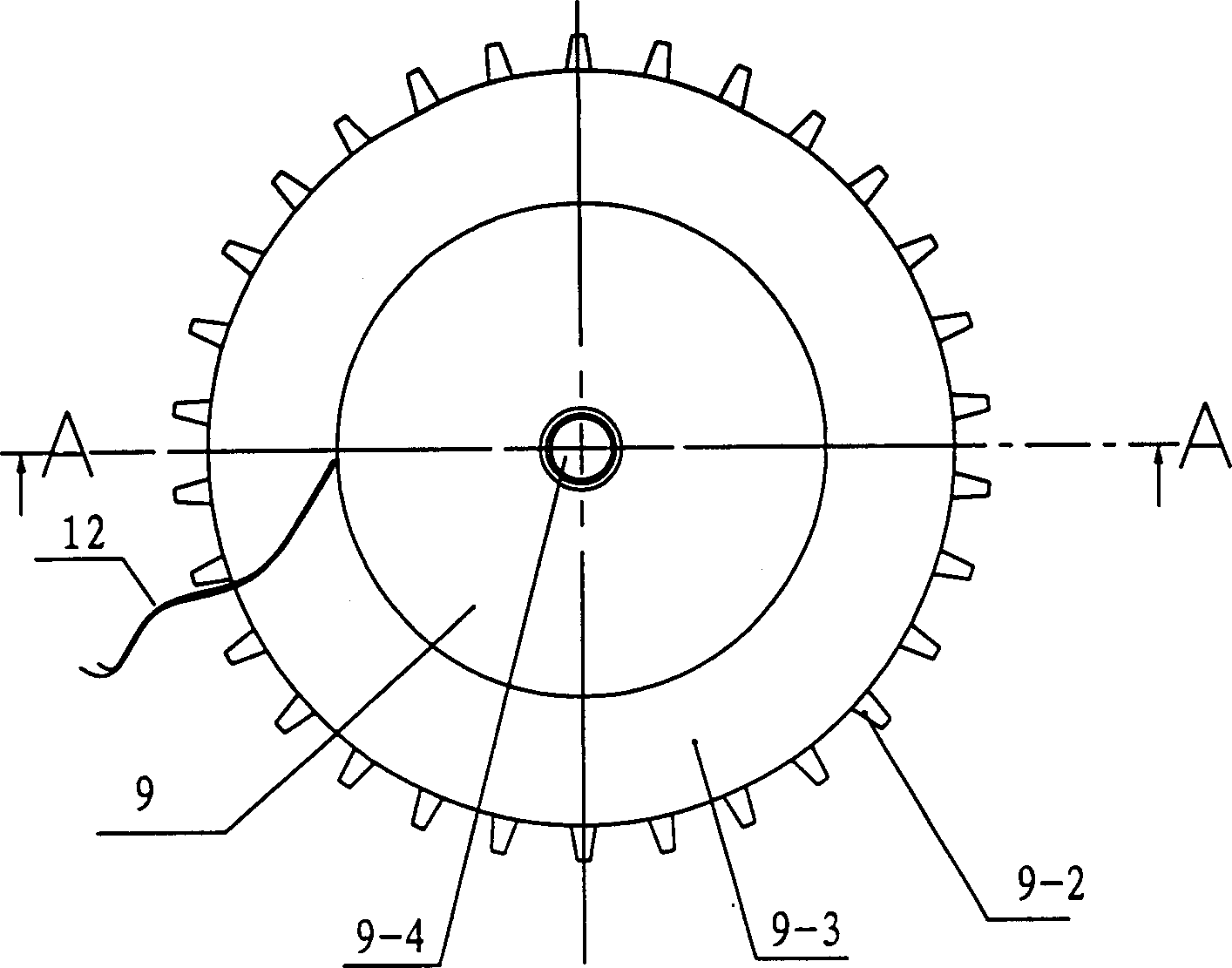

Integrated material feeder of sheet adhesive machine

InactiveCN1257662CIncrease placement speedHigh precisionPrinted circuit assemblingElectrical componentsGear driveRotor magnets

Owner:广州市羊城科技实业有限公司

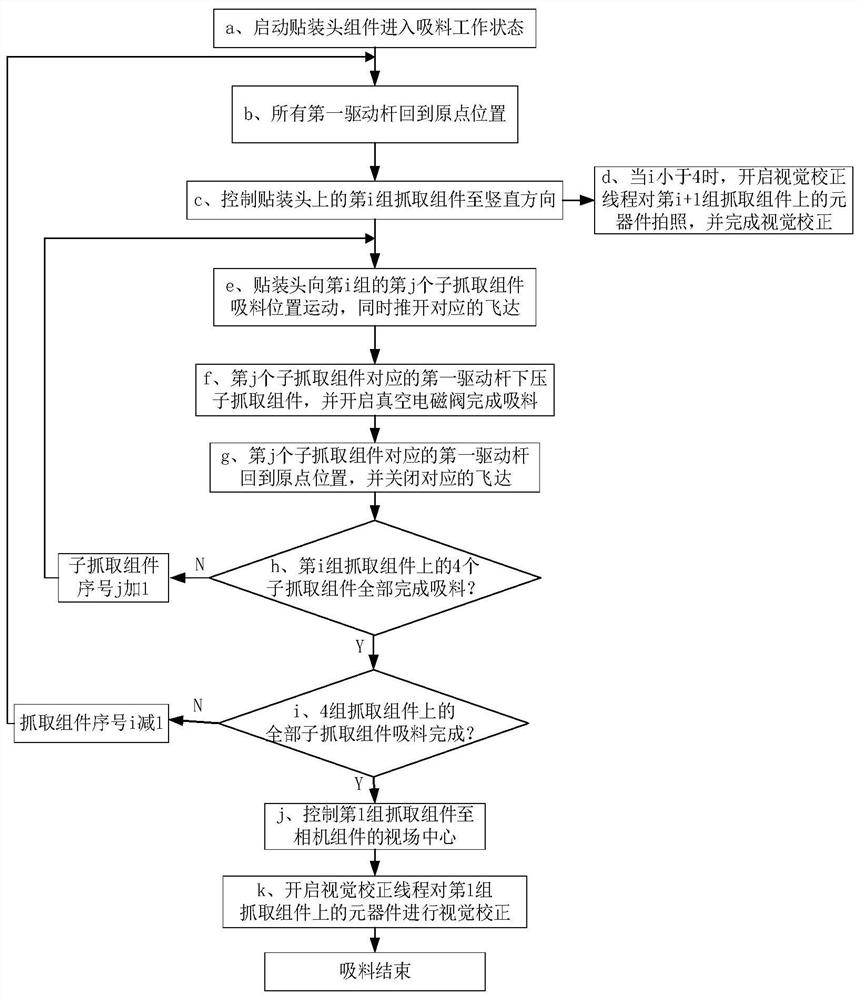

Ultrahigh-speed mounting head and chip mounter

The invention discloses an ultra-high-speed mounting head. The mounting head comprises a rack, a grabbing assembly used for grabbing or mounting components, and a horizontal turret assembly arranged on the rack. The horizontal turret assembly comprises a rotating shaft, and the grabbing assembly is arranged on the rotating shaft. According to the mounting head provided by the invention, the specific horizontal turret assembly is arranged, so that the mounting speed of the device, such as a chip mounter, etc., can be greatly improved on the premise of not increasing too much cost only by additionally arranging the grabbing assembly on the rotating shaft.

Owner:方强

An ultra-high-speed placement method and placement head

ActiveCN111343847BImprove accuracyIncrease placement speedElectrical componentsUltra high speedEngineering

Owner:方强

Bracket for drying large-outer-diameter and high-thickness blanks and implementation method of bracket

ActiveCN114044233ASpeed up placementFast dryingDrying gas arrangementsDrying chambers/containersCushionIndustrial engineering

The invention discloses a bracket for drying large-outer-diameter and high-thickness blanks. The bracket comprises a base, stand columns are arranged at the four corners of the upper portion of the base respectively, a top seat is arranged above the stand columns, a hanging rod is arranged above the top seat, a plurality of layers of supporting plates are arranged on the stand columns, each supporting plate comprises a bearing plate, and a plurality of filler strips are arranged above the bearing plate at equal intervals. The invention further discloses an implementation method of the bracket for drying the large-outer-diameter and high-thickness blanks. According to the blank drying device, the multiple filler strips are arranged above the bearing plates at equal intervals to support blanks, a cushion does not need to be placed any more, the blank placing speed is increased, air circulation is facilitated through the intervals between the filler strips, and therefore the blank drying speed is increased. The distances between the multiple layers of supporting plates are sequentially increased, the lower-layer air convection speed is increased, and therefore the drying speed of lower-layer blanks is increased, it is guaranteed that the drying speeds of the upper-layer blanks and the lower-layer blanks are consistent as much as possible, and the consistency of the water content of the blanks is guaranteed.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Whole-board mounting device and method in the production of surface-mounted quartz crystal resonators

ActiveCN106067775BShorten the timeIncrease productionImpedence networksQuartz crystal resonatorSurface mounting

Owner:SICHUAN MDH TECH CO LTD

Mounting head unit for electronic components

ActiveCN103889163BLower the altitudeSimple structurePrinted circuit assemblingElectrical componentsPositive pressureSurface mounting

The invention discloses a surface-mounted work head unit of an electronic component. The surface-mounted work head unit comprises a work head body, a transmission mechanism in the R-axis direction, a transmission mechanism in the theta-axis direction, a transmission mechanism in the Z-axis direction, a positive pressure air source, a negative pressure air source and a control mechanism. The transmission mechanism in the R-axis direction is connected with the work head body, the transmission mechanism in the theta-axis direction is respectively connected with the transmission mechanism in the R-axis direction and the work head body, and the transmission mechanism in the Z-axis direction is respectively connected with the work head body, the transmission mechanism in the R-axis direction and the transmission mechanism in the theta-axis direction. The surface-mounted work head unit is simple and compact in structure, light, high in surface mounting speed, low in inertia and high in reliability, and prolongs the service life of equipment.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Epidemic prevention queuing detection position ring placing vehicle

ActiveCN113022686AIncrease placement speedSave resourcesHand carts with multiple axesHand cart accessoriesControl theoryMechanical engineering

Owner:济南欣恩医疗科技有限公司

High Speed Dashboard Circuit Board Mounter

ActiveCN105120606BIncrease the number ofIncrease production capacityPrinted circuit assemblingSurface mountingHigh surface

The invention provides a high speed instrument panel circuit board surface mounting machine, which comprises a conveyor belt, surface mounting heads and a sliding rail, wherein the conveyor belt is arranged below the sliding rail; the surface mounting heads are mounted on the sliding rail via a motor; the sliding rail and the conveyor belt form a 90-DEG position relation; the lower side of the sliding rail is provided with a dispenser; a sensing element is arranged on the dispenser; and each surface mounting head is formed by a rotating shaft and suction nozzles, and the suction nozzles are closely arranged on the circumferential surface of the rotating shaft. As surface mounting is carried out by the surface mounting heads with multiple suction nozzles, the number for surface mounting can be increased, and productivity can be improved; as the front surface mounting head, the rear surface mounting head and the standby surface mounting head are arranged, surface mounting of a large number of elements can be completed while a high surface mounting speed is kept; the invested production cost is small, and the high speed instrument panel circuit board surface mounting machine can be used by medium and small-sized enterprises; and the structure is simple, and the invested cost is reduced while the surface mounting speed is improved.

Owner:WUHU HONGJING ELECTRONICS

Underwater plugging and water sealing method for bottom plate of concrete pouring jacket without back cover

InactiveCN101818500BSmooth hoistingSmooth alignment and placementFoundation engineeringStructural engineeringWater pressure

The invention discloses an underwater plugging and water sealing method for a bottom plate of a concrete pouring jacket without a back cover, which comprises the following steps: providing a concrete pouring jacket, a plurality of light-weight back cover templates and a plurality of jacks; hoisting and lowering the concrete pouring jacket; after the concrete pouring jacket arrives a designated position, hanging and fixing the concrete pouring jacket on steel pile casings of filling piles through a hanger above; at least installing the jacks between the inner side wall of the concrete pouring jacket and each steel pile casing of the filling piles; stabilizing the concrete pouring jacket to resist the influence of wind waves; installing and fixing the back cover templates in the water body below the bottom plate of the pouring jacket by a diver; arranging a longitudinal water inlet pore path and a concrete pouring filling area which can realize internal and external water pressure balance; selecting bag concrete; carrying the bag concrete and entering water by the diver and pouring the concrete into the pouring filling area; and finally plugging the longitudinal water inlet pore path to finish plugging and water sealing. The invention can accelerate the installing speed of the concrete pouring jacket and is especially favorable for carrying out the water sealing operation on thebottom plate of the concrete pouring jacket.

Owner:张 锦松 +1

An ultra-high-speed placement head and placement machine

The application discloses an ultra-high-speed placement head, the placement head includes a frame, a grabbing assembly for grabbing or mounting components, and a horizontal turret assembly arranged on the frame; the The horizontal turret assembly includes a rotating shaft on which the gripping assembly is arranged. The placement head of this application, because it is equipped with a unique horizontal turret assembly, can realize that it only needs to add a grabbing assembly on the rotating shaft, and can realize a substantial increase in the placement machine without increasing too much cost. The placement speed of the equipment.

Owner:方强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com