Paster apparatus of battery pole ear

A patch device and battery lug technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems that affect the processing and production of battery pole pieces, poor tape consistency, and high labor intensity, so as to achieve stable and reliable product quality , fast and accurate placement, and the effect of improving the speed of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A battery cover pressure detection device of the present invention will be further described in detail below in conjunction with the accompanying drawings:

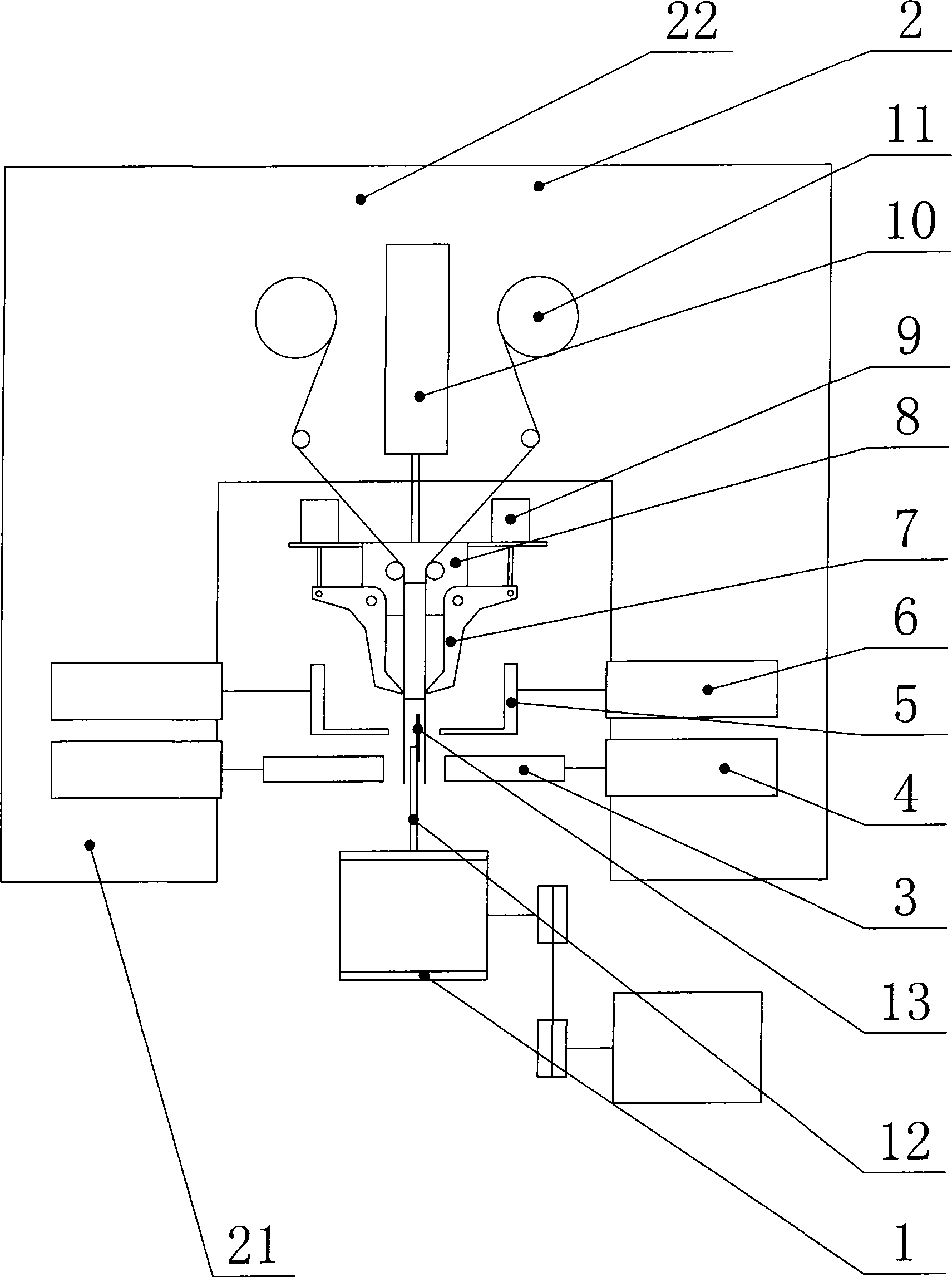

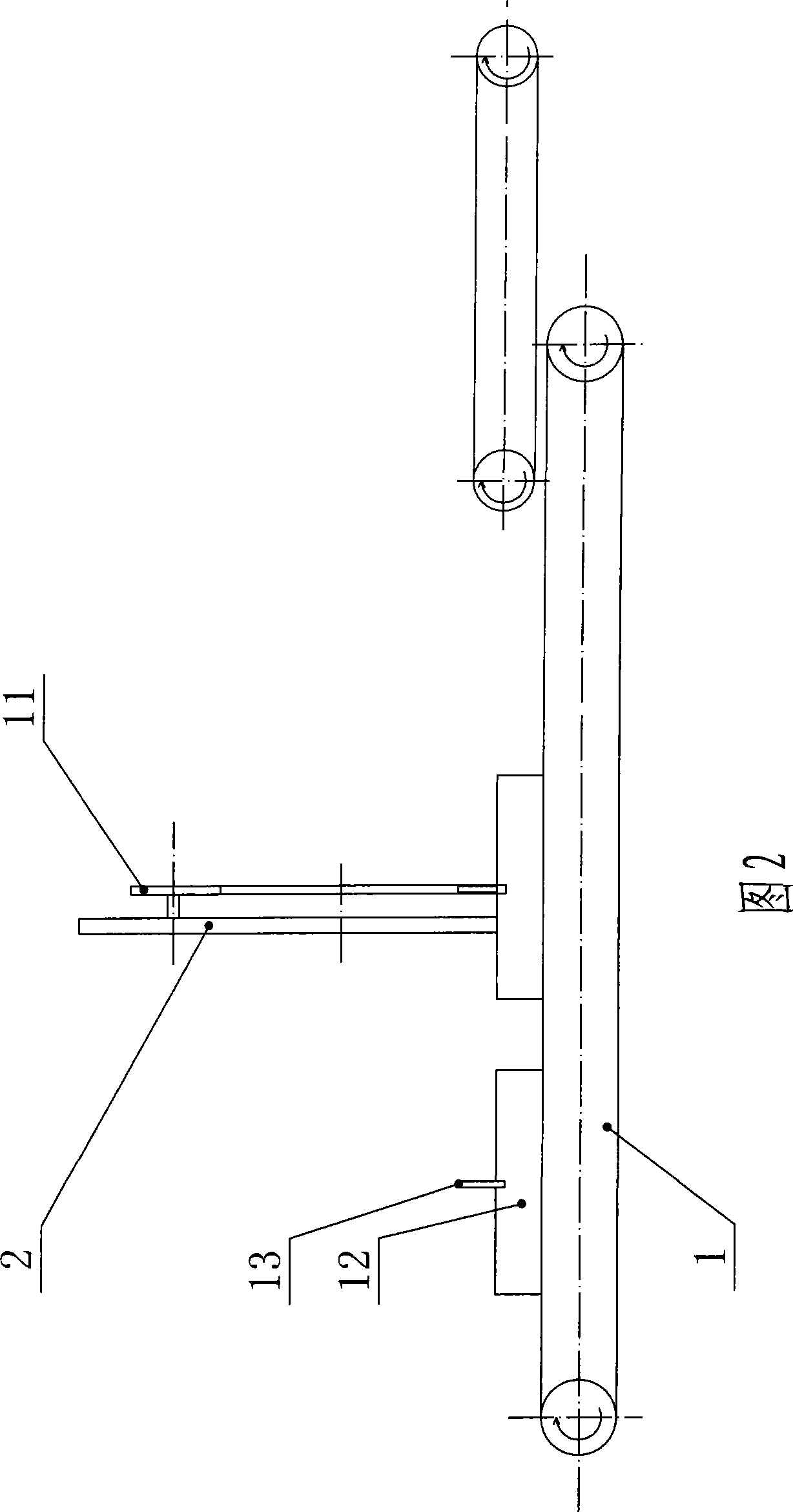

[0010] Such as figure 1 As shown in and 2, a patching device for battery tabs includes a conveyor belt 1 for pole pieces, and a column frame 2 arranged above the conveyor belt 1. The column frame 2 is composed of two columns 21 and a beam 22, and the two columns 21 A pair of pressing rods 3 are arranged above the conveyor belt 1 on the inner side, and the two pressing rods 3 are respectively connected with the pressing cylinders 4 arranged on the two columns 21. A pair of cutting shears 5 are arranged above the pressing rods 3, and the cutting shears 5 are respectively connected with the cutting cylinders 6 arranged on the two columns 21, a pair of curved chucks 7 are arranged above the cutting shears 5, and the middle parts of the two curved chucks 7 are respectively hinged on the lifting platform 8, and the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com