Underwater plugging and water sealing method for bottom plate of concrete pouring jacket without back cover

A technology for back-sealing concrete and concrete, which is applied in construction, infrastructure engineering and other directions, can solve the problems of high construction cost, failure to place concrete casings, and low cost in the whole construction cycle, and achieve the effect of speeding up the installation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

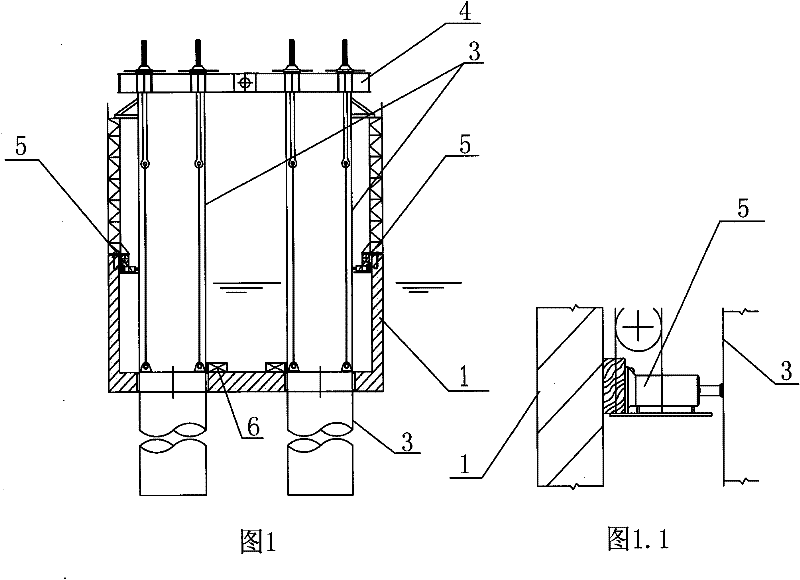

[0032] Combine figure 1 , An underwater sealing and water stopping method for the bottom plate of a concrete box without a bottom seal, comprising the steps:

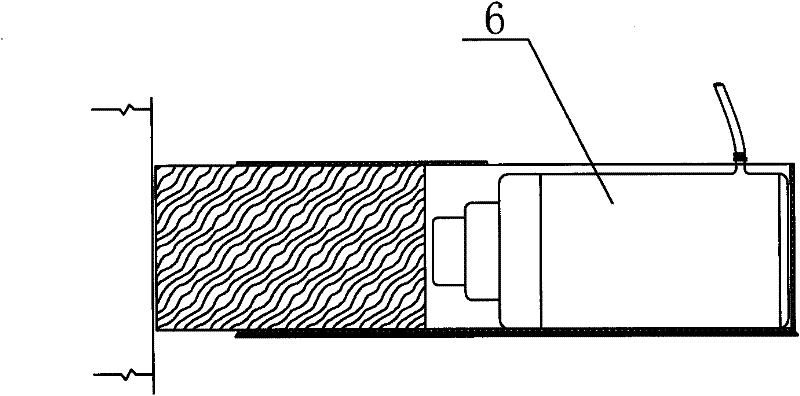

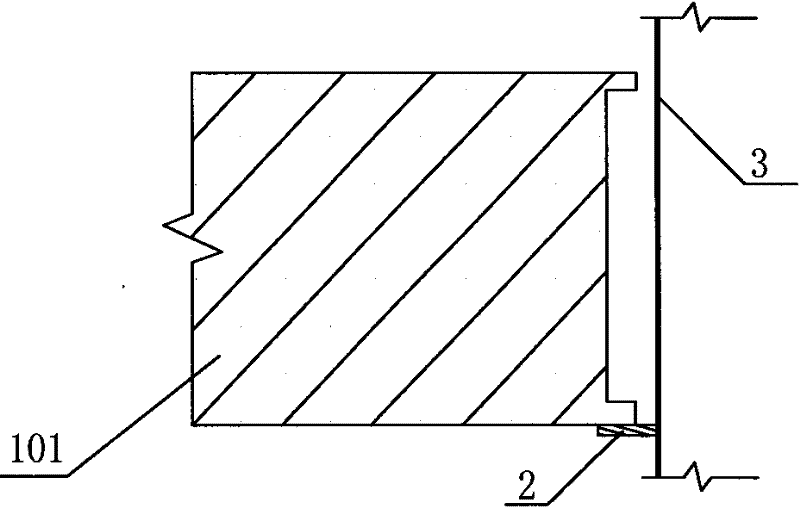

[0033] The step ① is to provide a set of concrete box 1, a number of light-weight back cover formwork 2 and a number of jacks. The box bottom plate 101 of the concrete box 1 is provided with a bottom plate circular hole. The bottom plate circular hole is used for the cast-in-place pile steel tube 3 to penetrate during the hoisting of the concrete box. The number of the cast-in-place pile steel tube 3 is the same as a set of concrete box The number of round holes in the bottom plate of 1 is the same, and each round hole of the bottom plate is only used for one cast-in-place pile steel protective tube 3 to penetrate. The diameter of the base plate circular hole is larger than the outer diameter of the cast-in-place steel protective tube. For the alignment and entry of the protective cylinder, the diameter of the circular hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com