Automatic pull-out type pull rod of two-plate type clamping mechanism

A two-plate and pull-out technology, which is applied in the field of two-plate mold clamping mechanism, can solve the problems of time-consuming, laborious and inconvenient disassembly of tie rods, and the failure of large molds to be successfully hoisted into the mold clamping mechanism from above to achieve the goal of improving mold fitability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

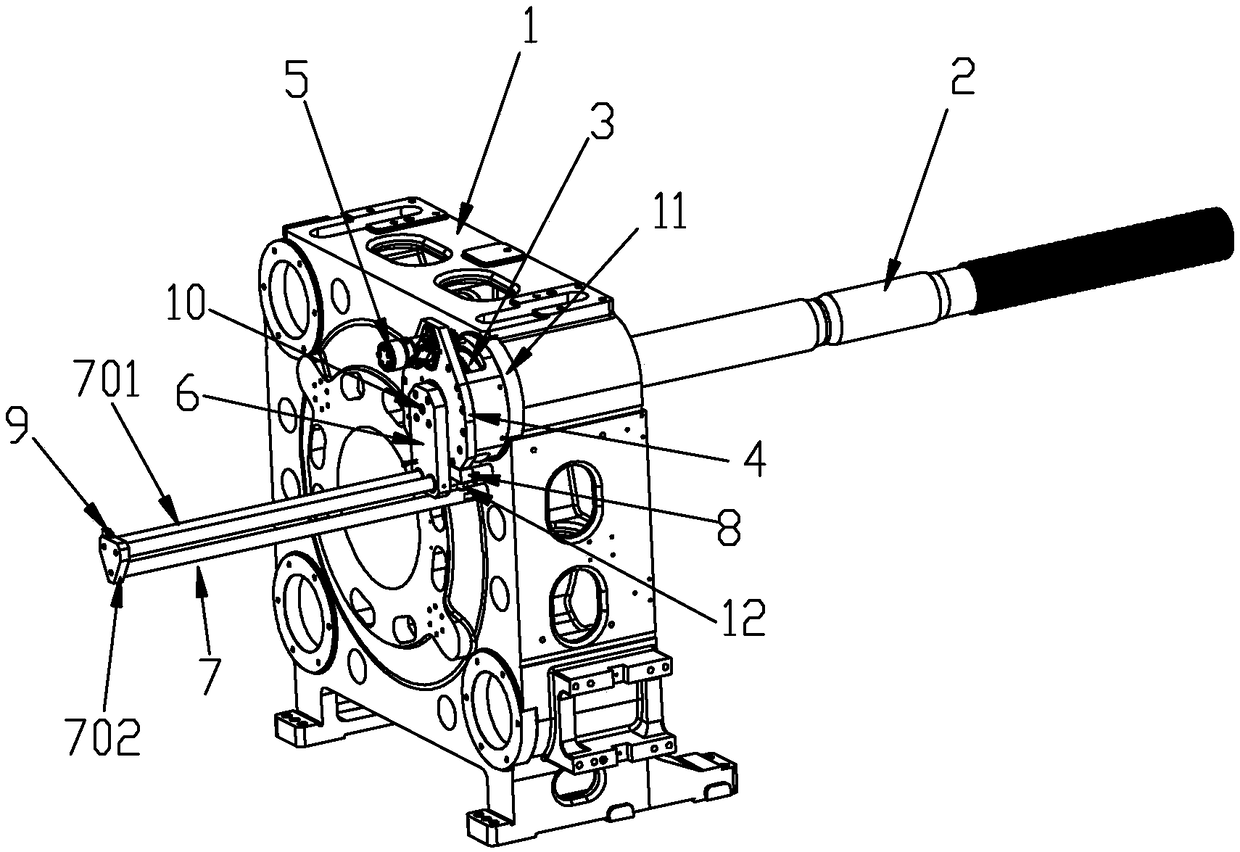

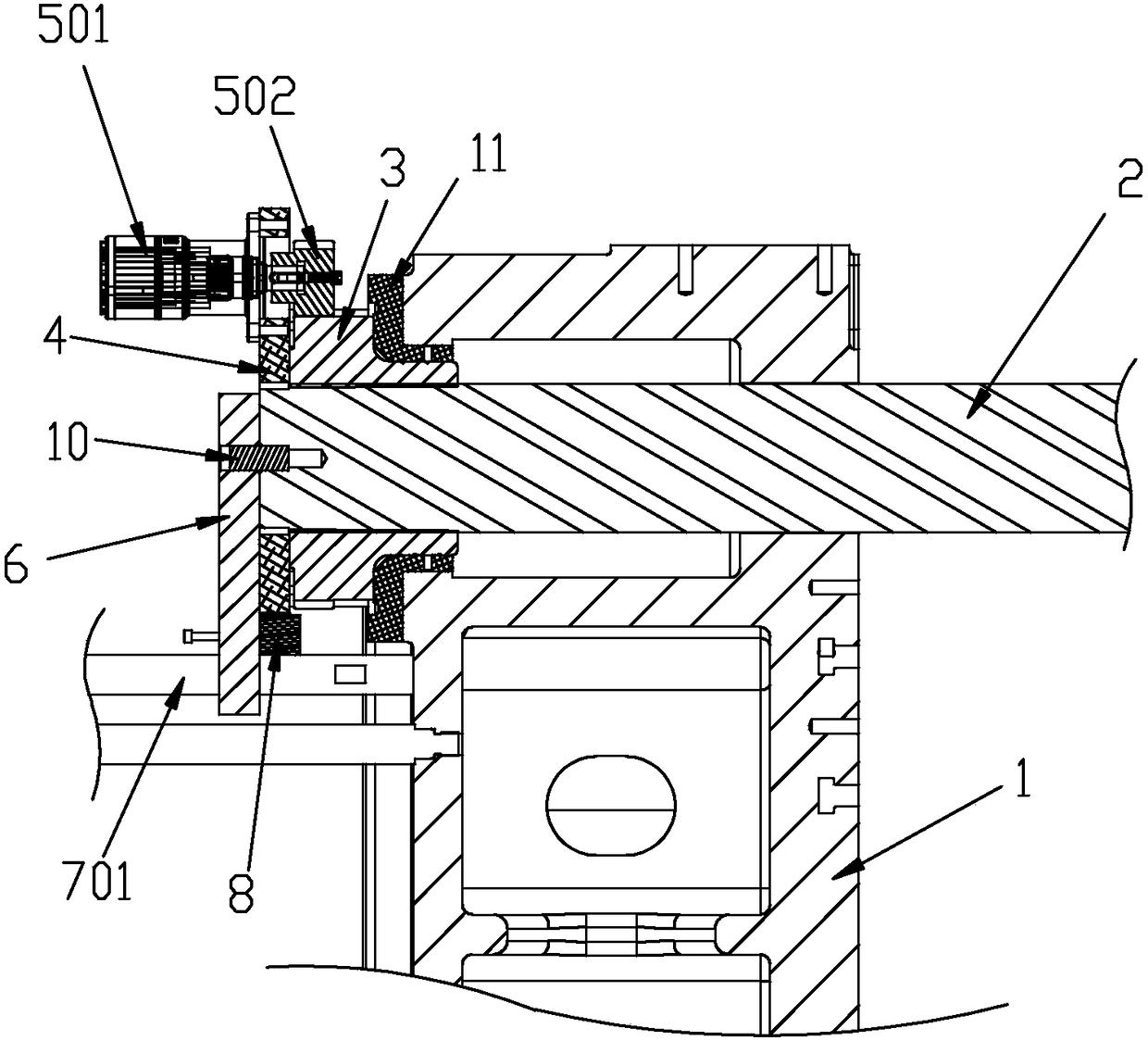

[0021] refer to Figure 1-2 :

[0022] An automatic pull-type tie rod 2 of a two-plate mold clamping mechanism, the rear end of the tie rod 2 is movably inserted into the rod hole provided on the outer side of the top of the fixed formwork 1, and the front end points to the movable formwork.

[0023] The outer hole end of the rod hole is fixedly equipped with an end cover 11, and the end cover 11 is rotatably provided with a tie rod nut 3, and the outside of the tie rod nut 3 is provided with a nut gland 4 for preventing its internal and external displacement.

[0024] The pull rod 2 is screwed into the pull rod nut 3 through the external thread set at its rear end, and its rear end passes through the pull rod nut 3 and the nut gland 4 and is fixedly connected with the slider 6, and the slider 6 is slidably connected to the fixed On the horizontal gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com