Center of gravity detection system for pipe gallery module

A detection system and pipe gallery technology, applied in the direction of measuring devices, machine/structural component testing, static/dynamic balance testing, etc., can solve problems such as local overload structure, low accuracy, instability, etc., and achieve accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

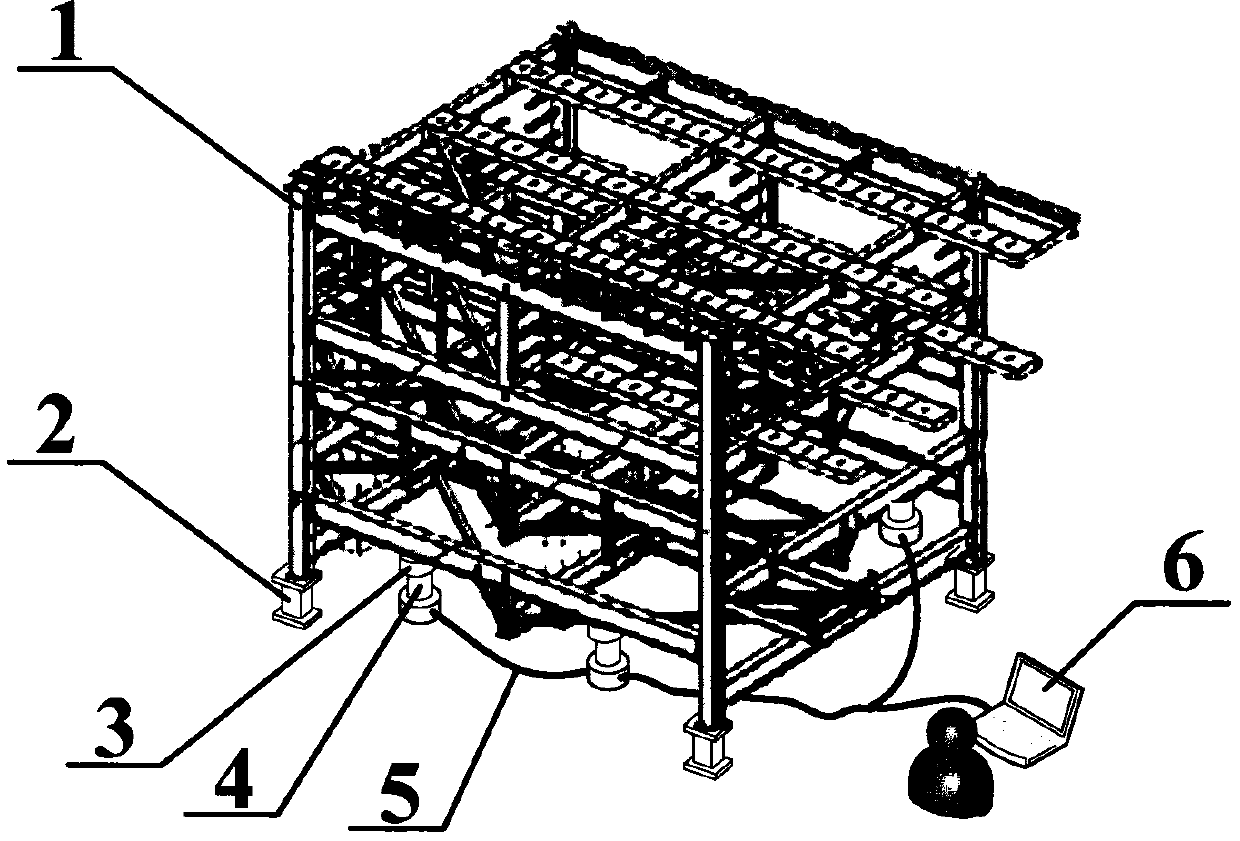

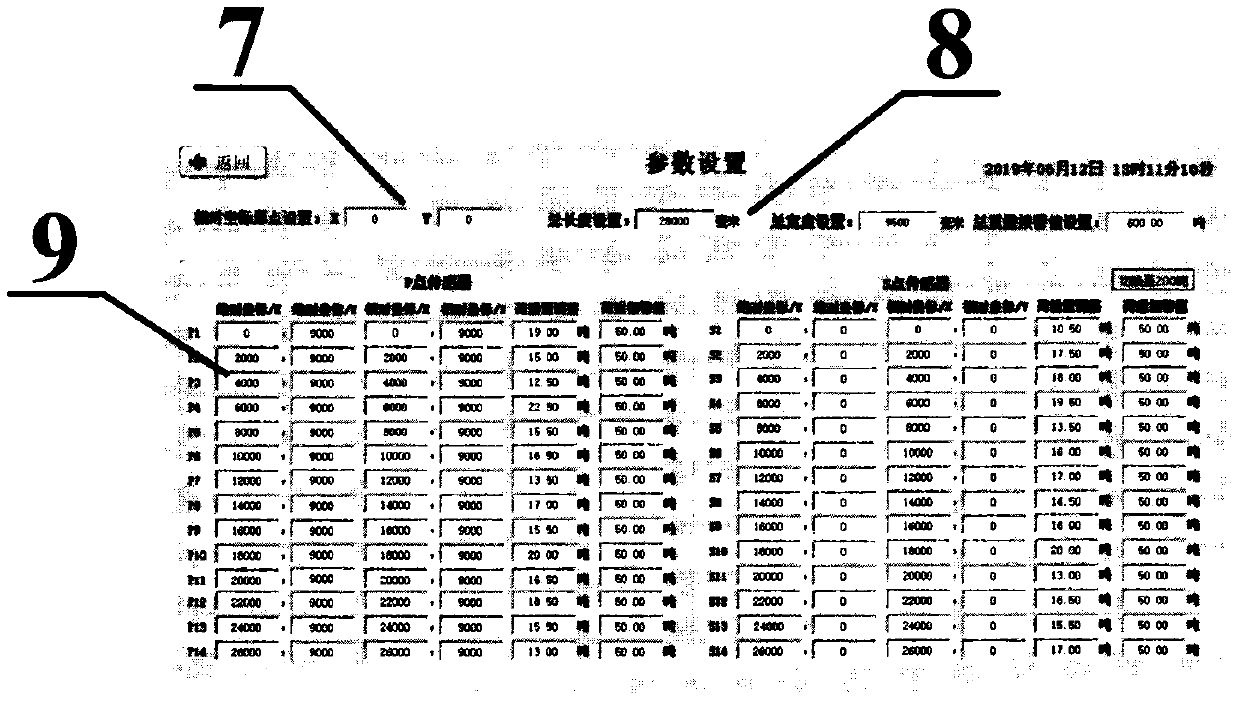

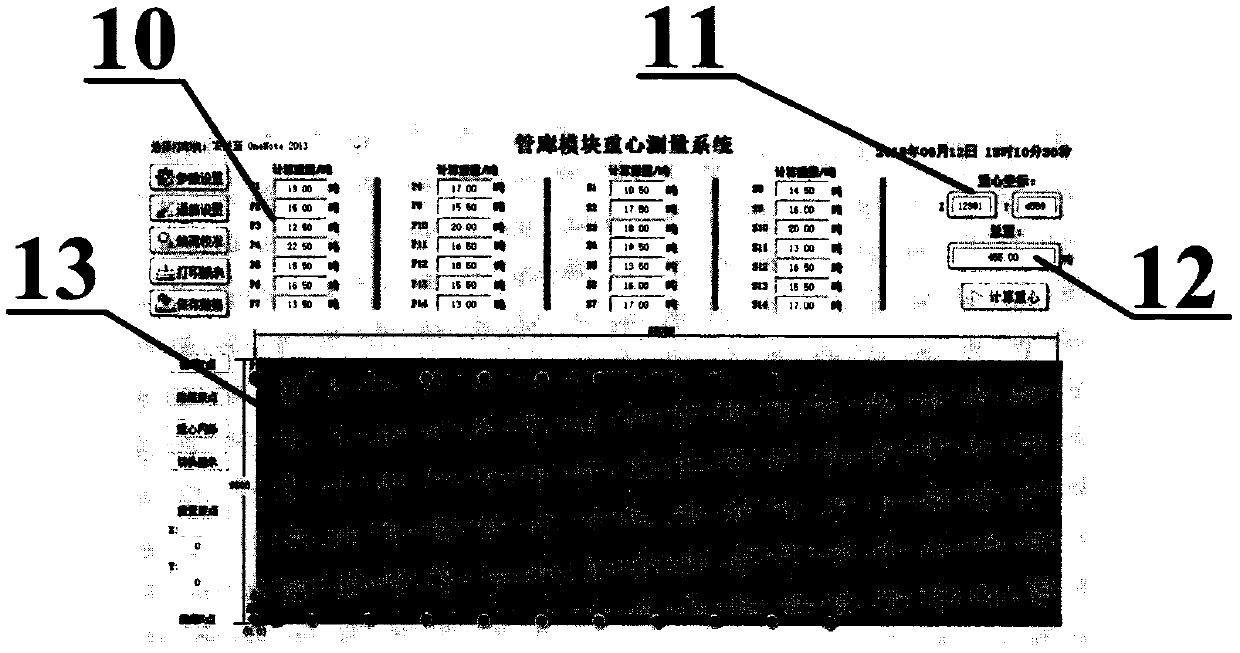

[0010] combined with Figure 1~3 The present invention is further described:

[0011] A detection system for the center of gravity of a pipe gallery module, the structure of which is as follows figure 1 As shown, it includes a pipe gallery module 1, a support frame 2, a load cell 3 and a hydraulic jack 4. Before the center of gravity detection, the pipe gallery module 1 is placed on the support frame 2, and the support frame 2 bears the entire pipe The weight of the corridor module 1; the load cell 3 is installed on the top of the hydraulic jack 4, and each load cell 3 and hydraulic jack 4 constitute a detection unit, which is generally installed in the pipe gallery according to the different specifications of the pipe gallery module. 10-28 detection units are placed under the module 1; before the detection starts, the load cell 3 is under the pipe gallery module 1, but not in contact with the pipe gallery module 1, so all the weight of the pipe gallery module 1 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com