Ultra-high-speed surface mounting method and surface mounting head

An ultra-high-speed, placement head technology, applied in electrical components, electrical components, etc., can solve the problems of low efficiency, low cost performance, and high production cost of placement machines, to improve placement speed, improve accuracy, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

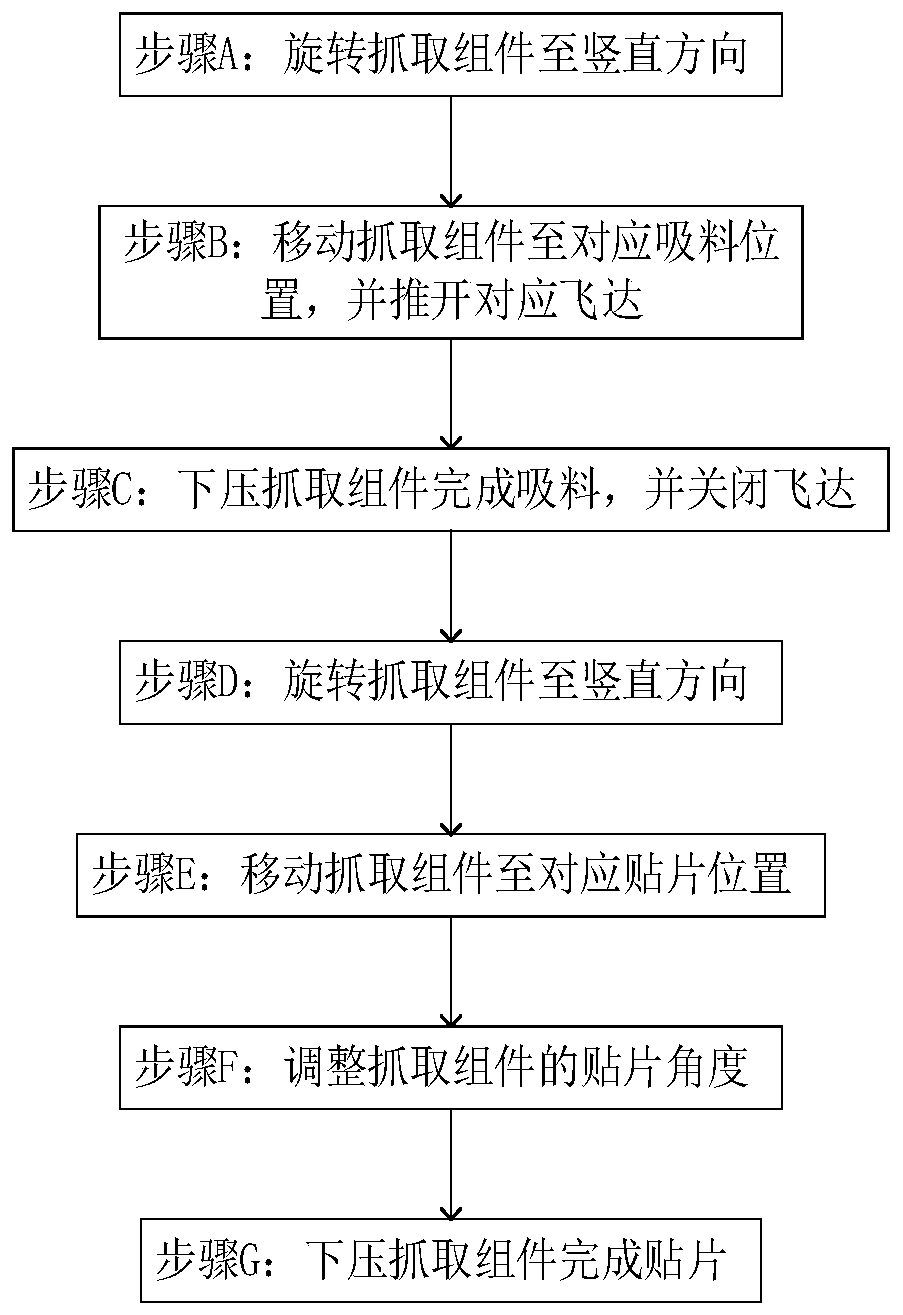

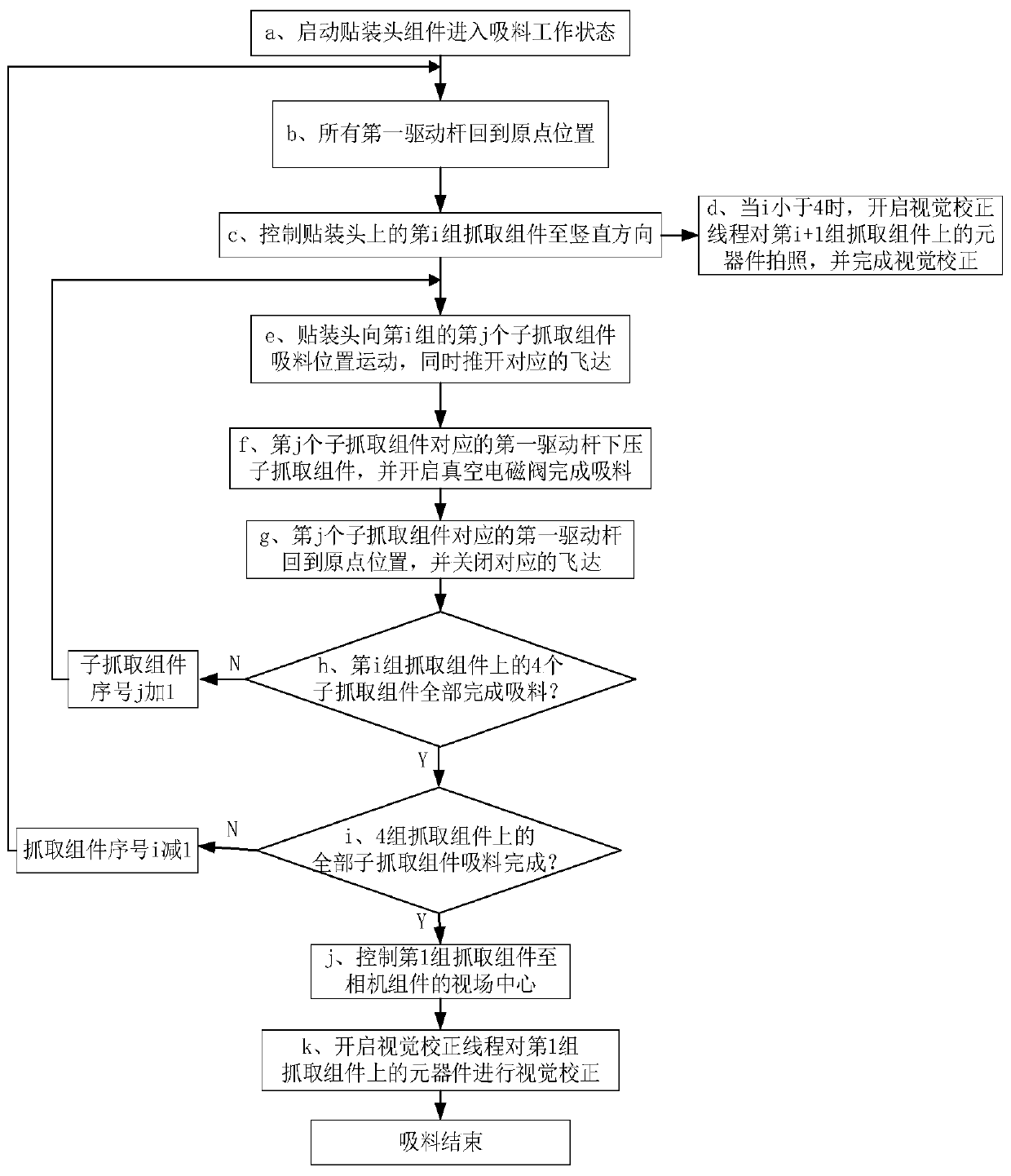

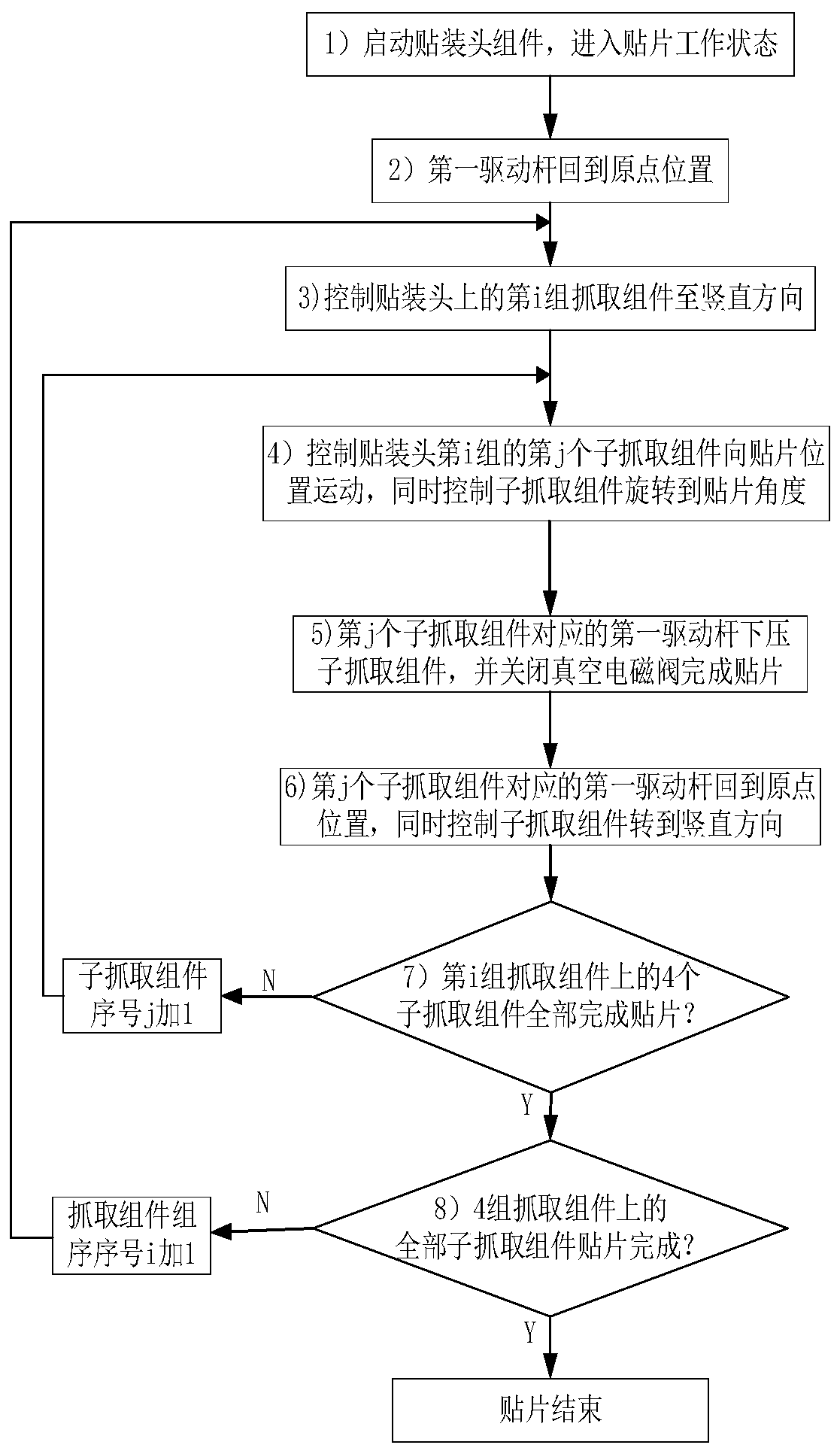

[0114] For the above method, for ease of understanding, steps A to C of the placement method can be collectively referred to as the suction method, and steps D to G can be collectively referred to as the placement method, and as an example, it is assumed that 4 sets of grabbing components are set (A row of sub-grabbing assemblies arranged in the same direction along the direction of the shaft center line of the horizontal turret assembly is a group), each group of grabbing assemblies has 4 sub-grabbing assemblies, that is, n=4, m =4. Each sub-grabbing assembly has a suction nozzle for picking up components, so there are 12 sub-grabbing assemblies and suction nozzles in total. Taking this as an example, the specific implementation of the ultra-high-speed patch method of the present application is as follows:

[0115] Such as figure 2 As shown, the steps A to C collectively referred to as the suction method are complete and detailed as follows:

[0116] a. Start the placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com