Integrated material feeder of sheet adhesive machine

A feeder and integrated technology, which is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, etc., can solve the problem of feeding accuracy that is difficult to meet high-speed, high-precision feeding, inaccurate material position compensation or correction, and feeding Unreasonable device structure and other problems, to achieve the effect of enriching control modes, improving precision, and increasing placement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

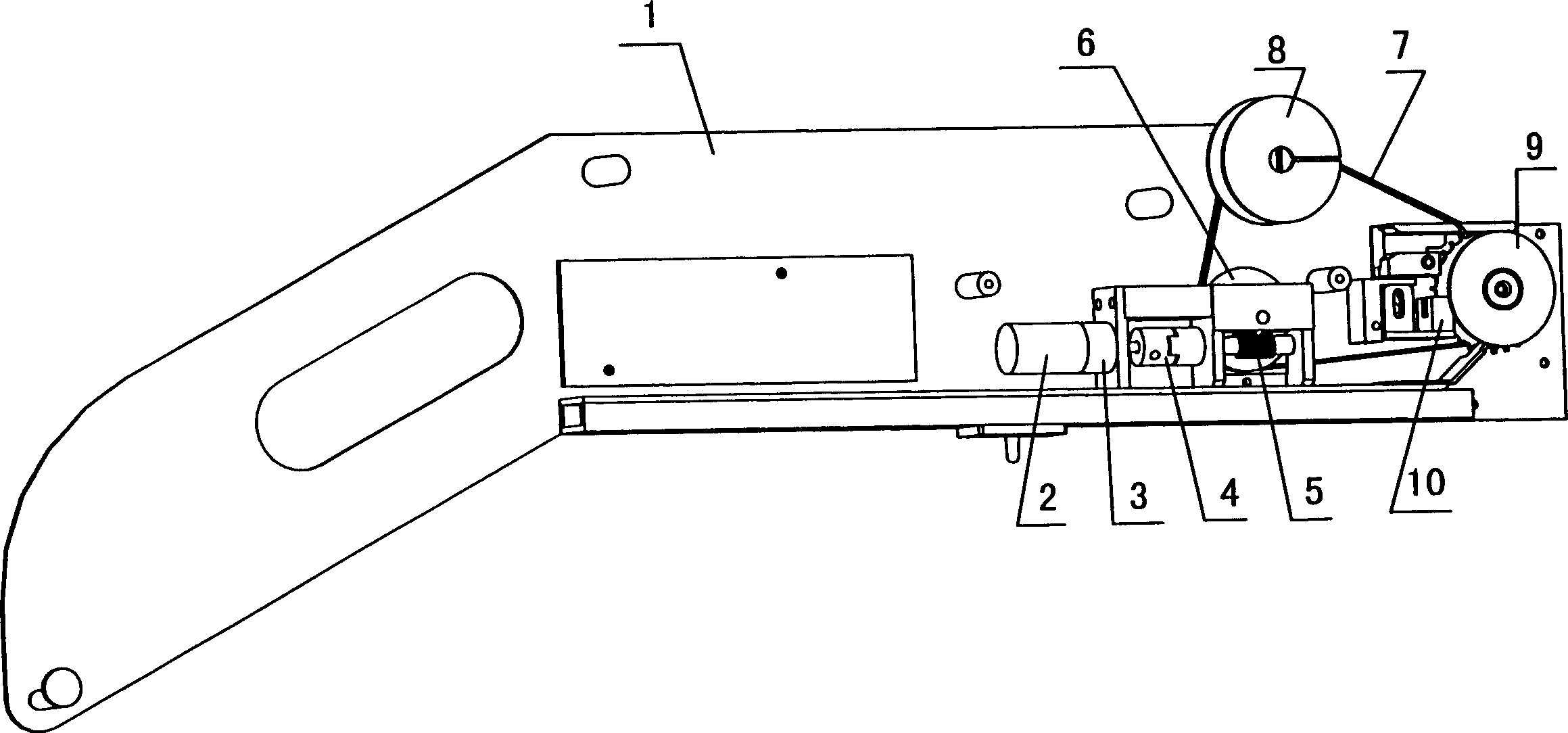

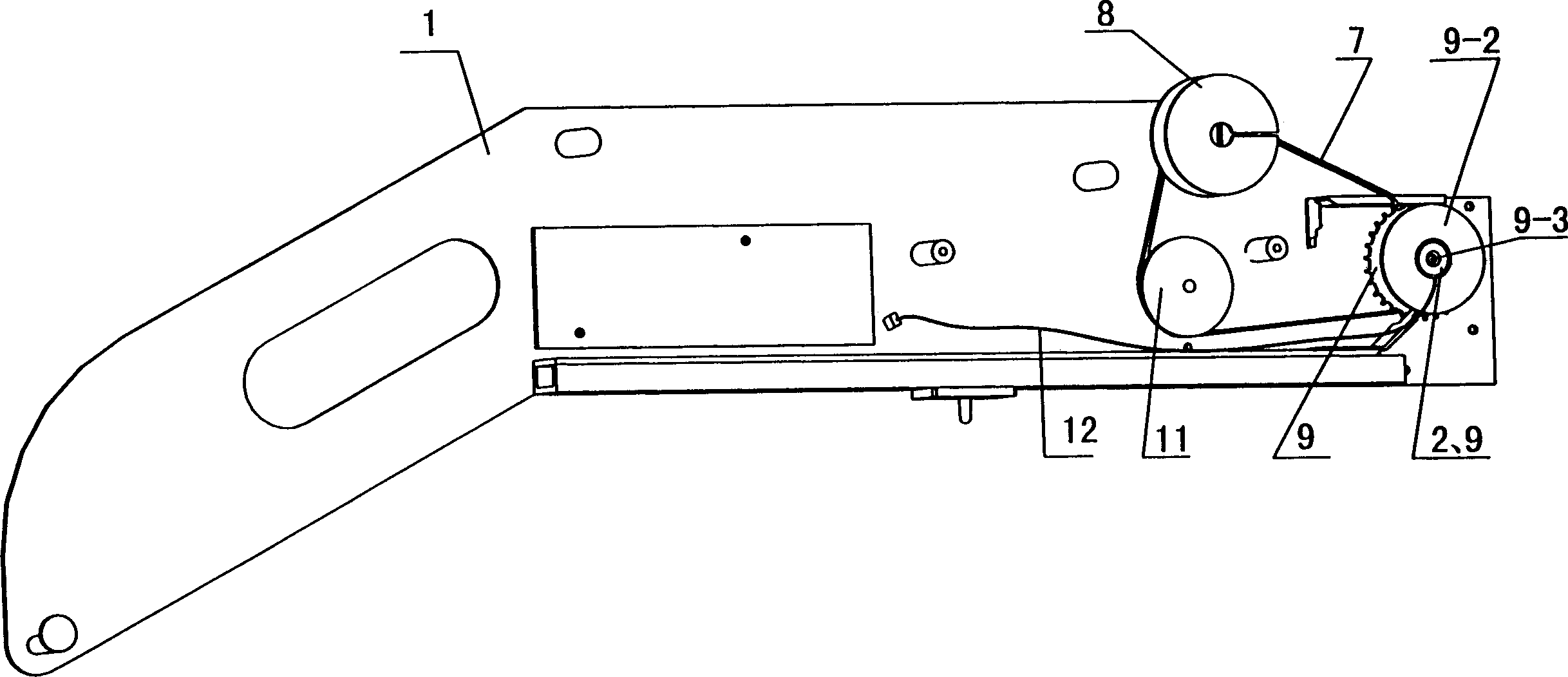

[0022] Embodiments of the present invention,

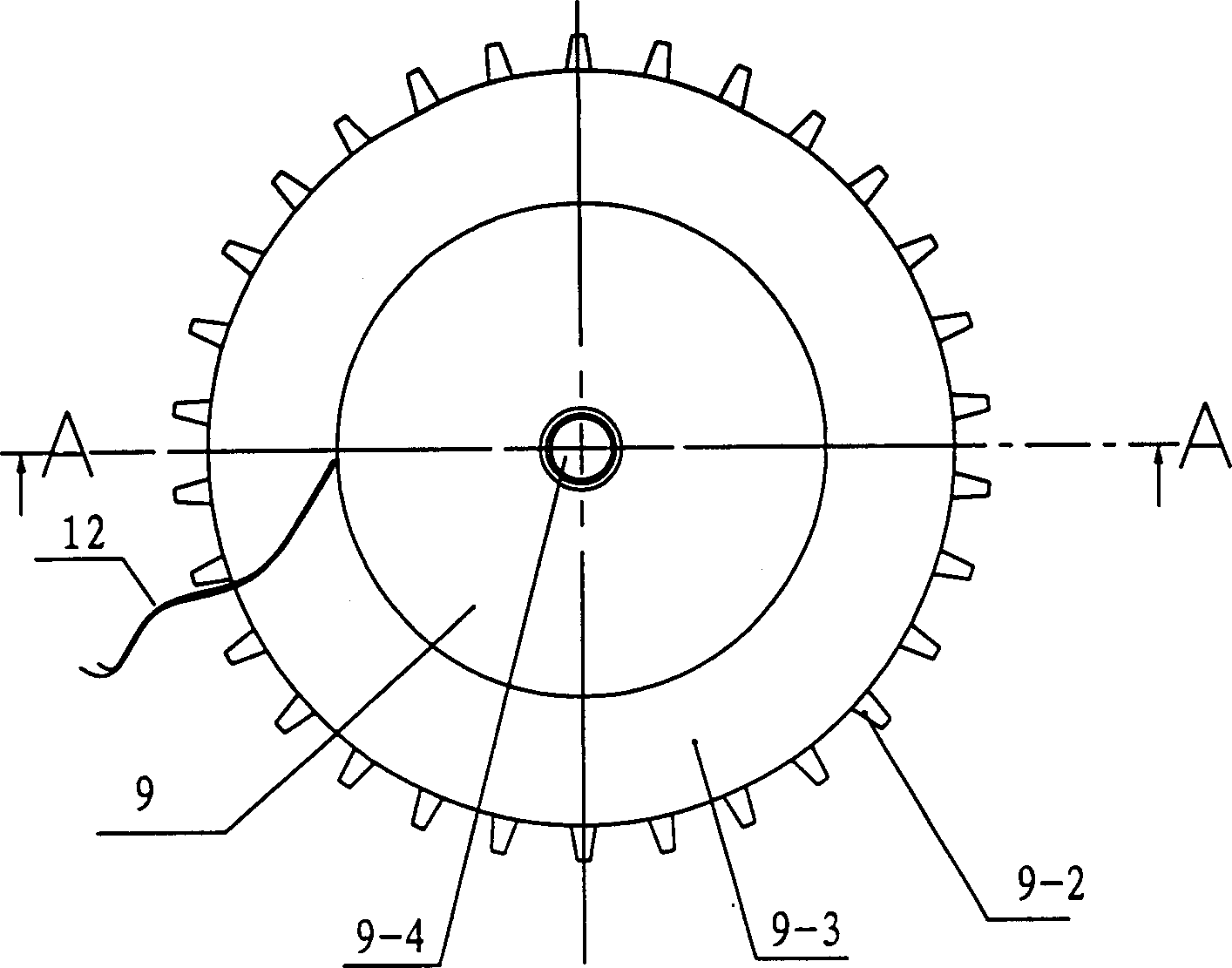

[0023] Such as figure 2 , 3 , Shown in 4 and 5: the integrated feeder of the placement machine of the present invention has the following parts on the support plate 1 of the integrated feeder: the active feed wheel integrated with the drive motor linked with the synchronous belt 7 9. Peeling wheel 8, in the active feeding wheel 9 integrated with the drive motor, the synchronous transmission gear 9-1, the feeding gear 9-2 and the annular supporting wheel 9-3 with the same rotation center are connected to form a column wheel cavity 9-0, and a stator coil 2-0 is installed in its cylindrical wheel cavity 9-0, and a rotor coil 2-1 is installed on its original wheel shaft 9-4; the wheel cavity 9 -0 cooperates with the wheel shaft 9-3 by two rolling bearings 9-5 in the axial direction.

[0024] The axle 9-4 of the active feeding wheel 9 is fixed on the support plate 1 of the integrated feeder;

[0025] The synchronous transmission g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com