Whole plate die attach device and method during production of surface mount type quartz-crystal resonator

A technology for quartz crystals and resonators, which is applied in the field of whole-board mounting devices in the production of surface-mounted quartz crystal resonators. It can solve the problems of low production efficiency, large demand for coating fixtures, and slow circulation, etc., and achieves improved production efficiency and expansion. SMT throughput and the effect of increasing the SMT speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

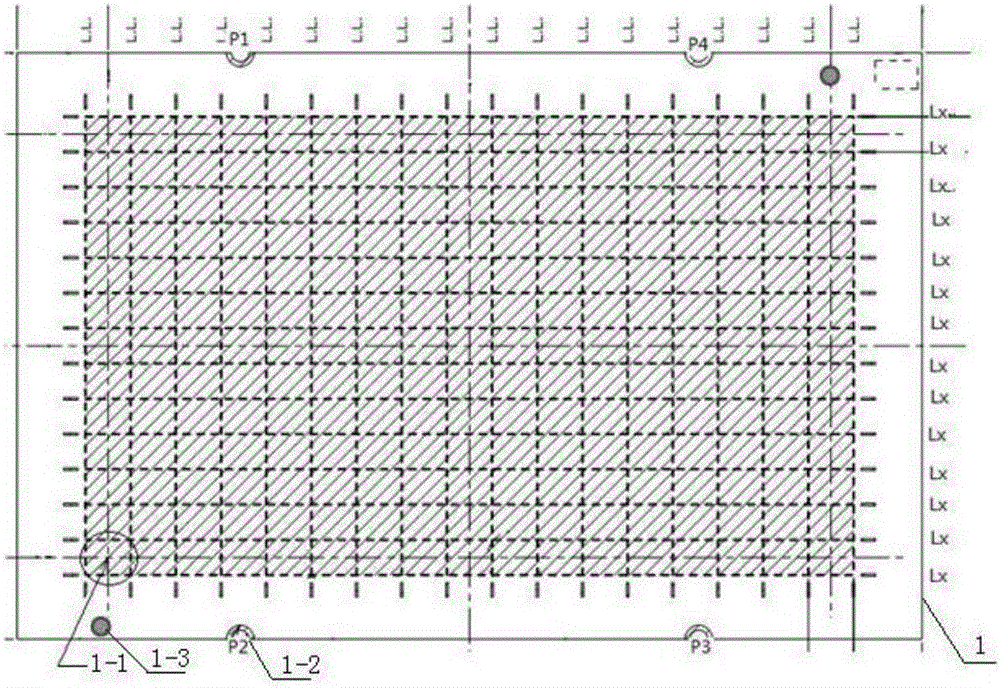

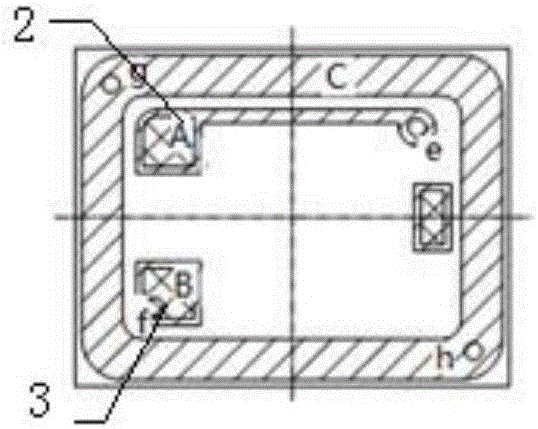

[0061] In this embodiment, the rows and columns of the entire wafer on the coating fixture are the same as the row and column spacing of the entire base, that is, after the primer coating process for all the monomer bases on the entire base is completed, all the monomer bases The seat is loaded with the film process at the same time. In this embodiment, the entire wafer on the coating fixture is a P*Q matrix, and the entire base is an M*N matrix, P=M, Q=N. When the entire base is After the left and right platforms of each monomer base are coated with primer, follow the steps below to move and place the entire wafer. The specific loading process is as follows:

[0062] Step 1. Place the entire wafer placed in the coating fixture into the wafer cage, the number of each wafer on the entire wafer, the number of suction nozzles in the suction box, and the number of single bases on the entire base be consistent;

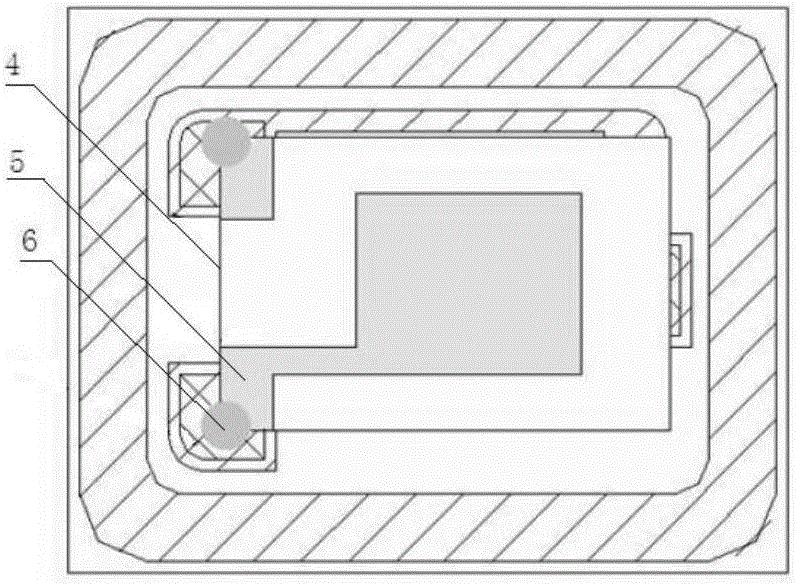

[0063] Step 2. Install the coating fixture with the whole wafer in t...

Embodiment 2

[0069] In this embodiment, the process of moving the entire wafer on the coating jig to the entire base is similar to that of Embodiment 1, except that the array of wafers on the coating jig in this embodiment is the same as that of the entire base. The distance between rows and columns is twice, for the entire wafer on the coating fixture is a P*Q matrix, and the entire base is an M*N matrix, P=2M, Q=2N, that is, all the monomer substrates on the entire base are completed After the primer coating process of the base, the single base located on the entire board of the base with odd rows and columns or even rows and columns is simultaneously subjected to the chip loading process. In this embodiment, the single base with odd rows and odd columns on the entire base is selected first, and then the single base with even rows and even columns on the entire base is coated.

[0070] After the left and right platforms of each single base on the entire base board are coated with primer,...

Embodiment 3

[0079] In this embodiment, the process of moving the entire plate wafer on the coating fixture to the entire base plate is similar to Embodiment 1, the difference is that in this embodiment, the coating fixture is installed in the suction box, and the suction box is turned over. All done manually.

[0080] In addition, in this embodiment, the rows and columns of the entire wafer on the coating fixture are three times the row-column spacing of the entire base. For the entire wafer on the coating fixture, it is a P*Q matrix, and the entire base is an M*N matrix. P = 3M, Q = 3N, that is, after the primer coating process of all monomer bases on the entire base board is completed, the monomer bases on the entire base board separated by two rows and two columns are simultaneously applied. piece craft. Taking the 12*12 base board as an example, in this embodiment, the first, 4th, 7th, and 10th rows and 1st, 4th, 7th, and 10th rows of the base board are first selected. Put on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com