Modular high-speed mounting head for LED (light emitting diode) mounting

A placement head and modular technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of complex structure, bulky size, high cost, etc., and achieve the advantages of simple structure, reasonable layout and increased placement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the technical content, characteristics and principles of the present invention, and cooperate with accompanying drawings to describe in detail as follows:

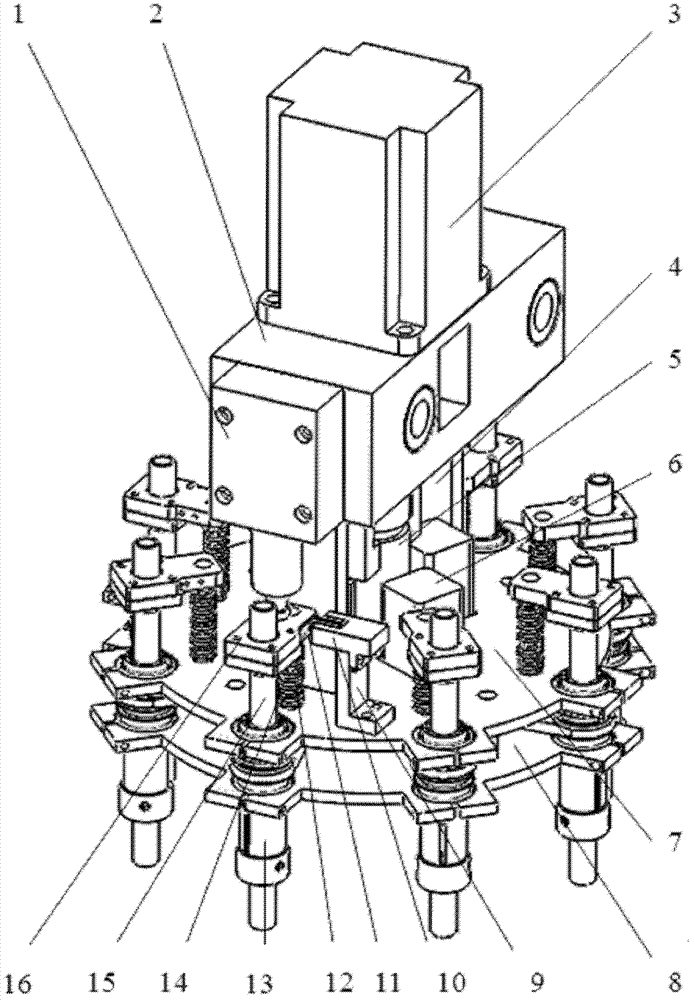

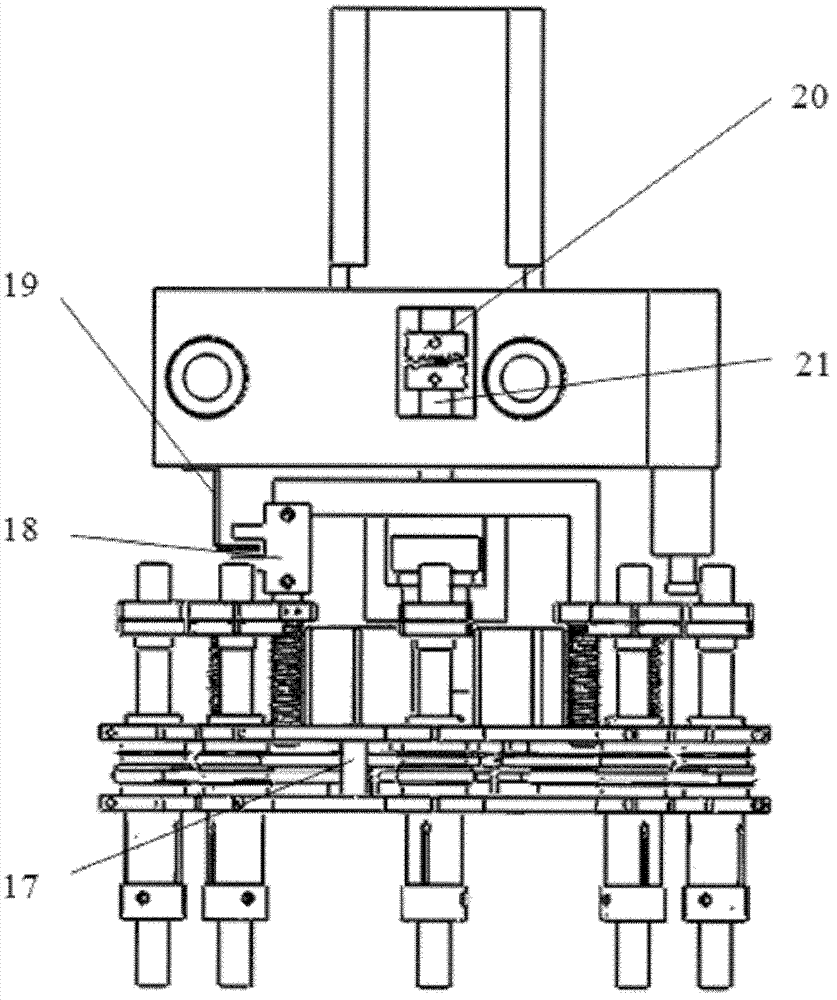

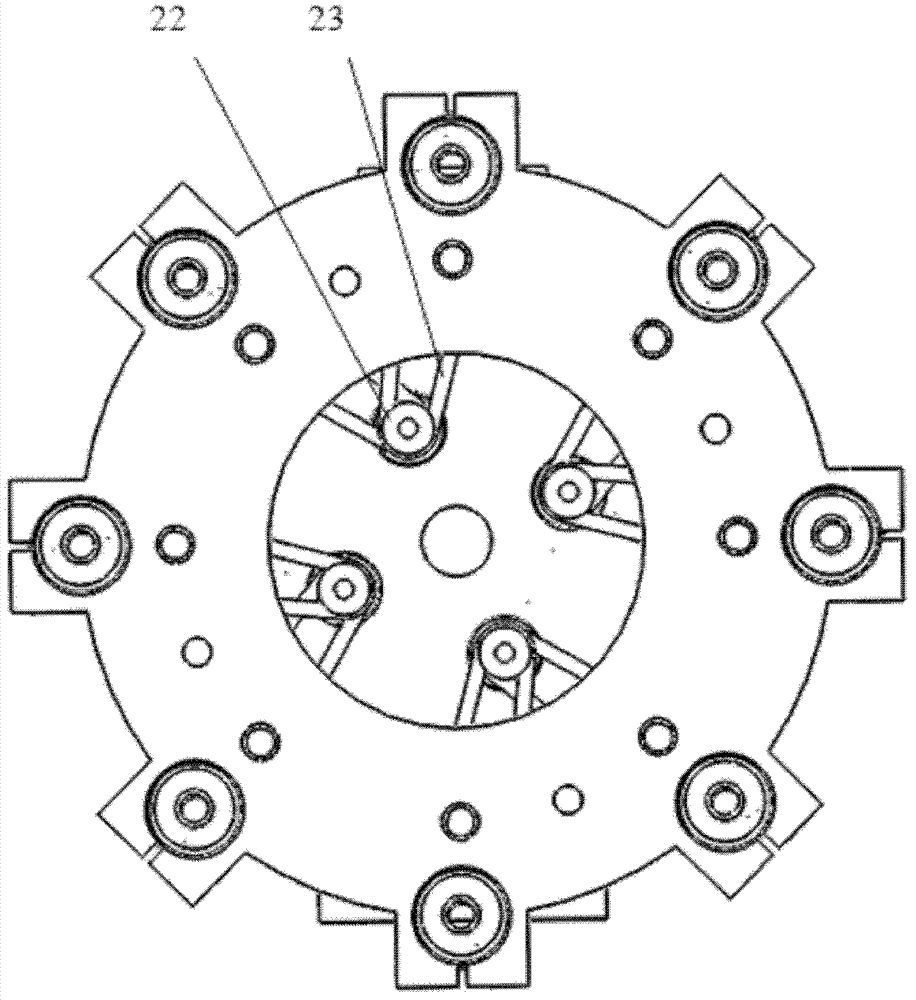

[0022] like figure 1 , 2 , 3, 4, the present invention is a modular high-speed placement head for LED placement, the placement head includes a turntable rotation mechanism, suction nozzle lifting mechanism, suction nozzle rotation mechanism, electrical protection and interface conversion device and the suction nozzle 15, the turntable rotation mechanism is composed of a mounting head holder 2, a DC servo motor 3, a turntable shaft 21, a turntable connection frame 4, a first turntable 7 and a second turntable 8, wherein the DC servo motor 3 is fixed on the mounting head fixing base 2 by screws, one end of the turntable shaft 21 is installed on the mounting head fixing base 2 through a bearing and coupled with the output end of the DC servo motor through a coupling 20, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com