Safety shoe heel fabric assembly sewing template tool and sewing method

A technology for safety shoes and components, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problem that the heel fabric component 1 cannot be applied, and achieve the effect of avoiding moving the neckline, improving sewing efficiency, and reducing manual participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

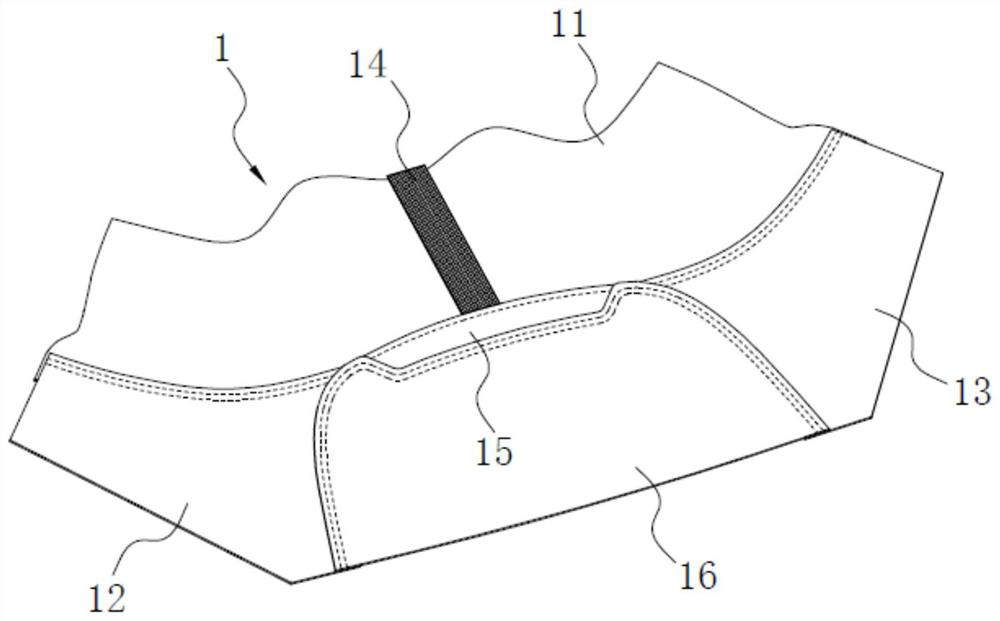

[0048] This embodiment provides a safety shoe heel fabric component sewing template tooling, which is specially used for sewing such as figure 1 The heel fabric assembly 1 shown in , the heel fabric assembly 1 includes six pieces of fabrics: the neckline 11 , the left row 12 , the right row 13 , the webbing 14 , the reflector 15 and the heel 16 . Refer below Figure 2 to Figure 5 As shown, the template tooling will be described in detail.

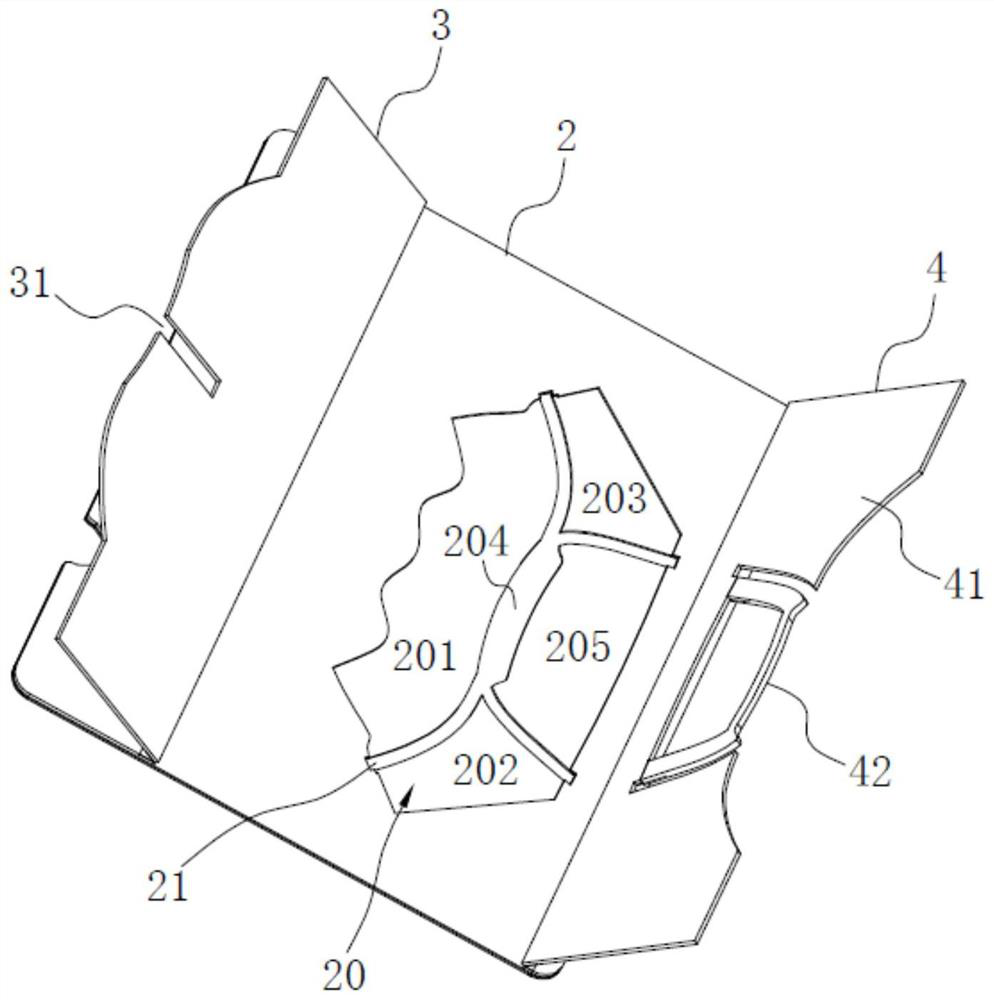

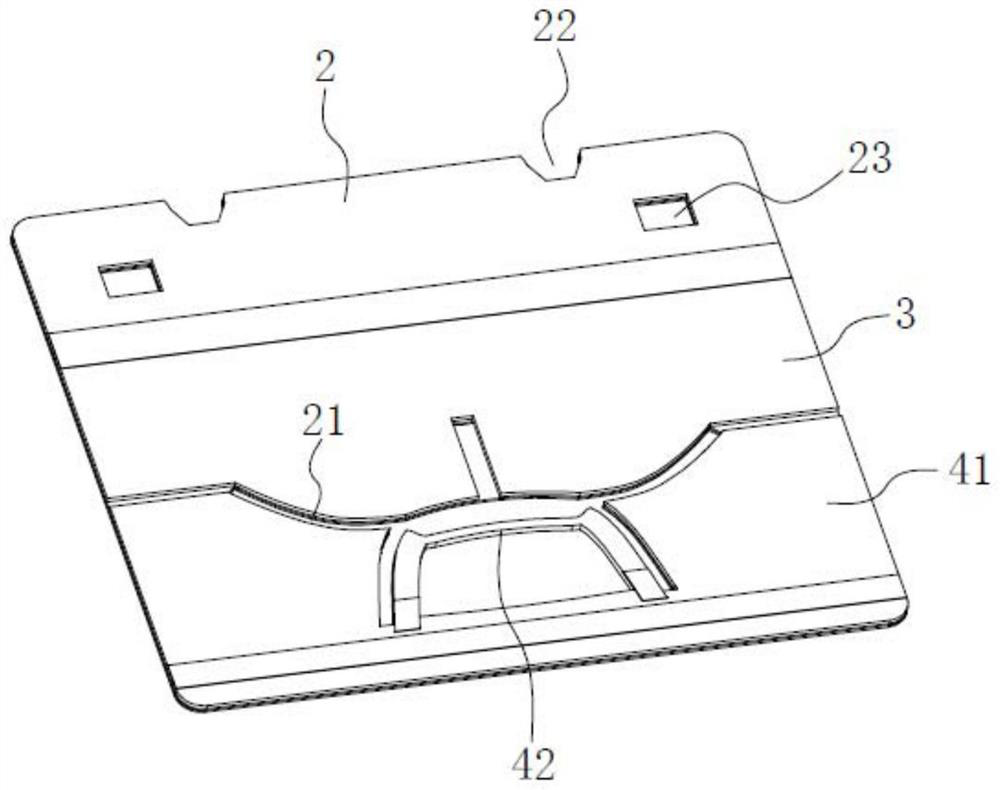

[0049] The formwork tooling includes a bottom plate assembly 2, a first pressing plate 3 and a pressing plate assembly 4, and the first pressing plate 3 and the pressing plate assembly 4 cover the bottom plate assembly 2 and can be opened. The middle of the bottom plate assembly 2 has a positioning groove 20 for accommodating the heel fabric assembly 1 and a needle running seam 21 corresponding to the needle running route. After the first pressing plate 3 and the pressing plate assembly 4 are covered, the position corresponding to the needle...

Embodiment 2

[0060] The basic structure of the safety shoe heel fabric component stitching template tooling in this embodiment is the same as that of Embodiment 1. The differences and improvements are as follows: figure 1 As shown in , the first pressing plate 3 is provided with an escape groove 31 for accommodating the webbing 14 , and the escape groove 31 is used for locating the position of the webbing 14 .

[0061] When sewing the heel fabric component 1, first place the neckline 11 in the corresponding neckline positioning area 201, and turn over the first pressing plate 3 to press the neckline 11; then place the left row 12, Right row 13, webbing 14 and reflector 15.

[0062] When placing the webbing 14 , the positioning slot 31 is used for positioning, which can ensure the accurate positioning of the webbing 14 . In addition, after the first pressing plate 3 is closed, the other pieces of fabrics mentioned above can be placed, which can avoid accidentally moving the neckline 11 dur...

Embodiment 3

[0064] The basic structure of the safety shoe heel fabric assembly stitching template tooling in this embodiment is the same as that of Embodiment 2. The differences and improvements are as follows: Figure 5 As shown in the figure, both ends of the first needle running seam 211 and the second needle running seam 212 have needle openings 213 that extend beyond the edge of the positioning groove 20 .

[0065] The needle raising port 213 is used to raise the needle during sewing, so as to prevent the sewing needle from being stuck on the plate due to the position of the needle raising being too close to the plate at the end of the needle seam, thereby reducing the occurrence of needle breakage during needle raising.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com