Laser cutting and positioning tool

A positioning tooling and laser cutting technology, which is applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of affecting processing quality, affecting processing speed, and cumbersome positioning methods, so as to achieve good cutting quality and save materials , Positioning convenient and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

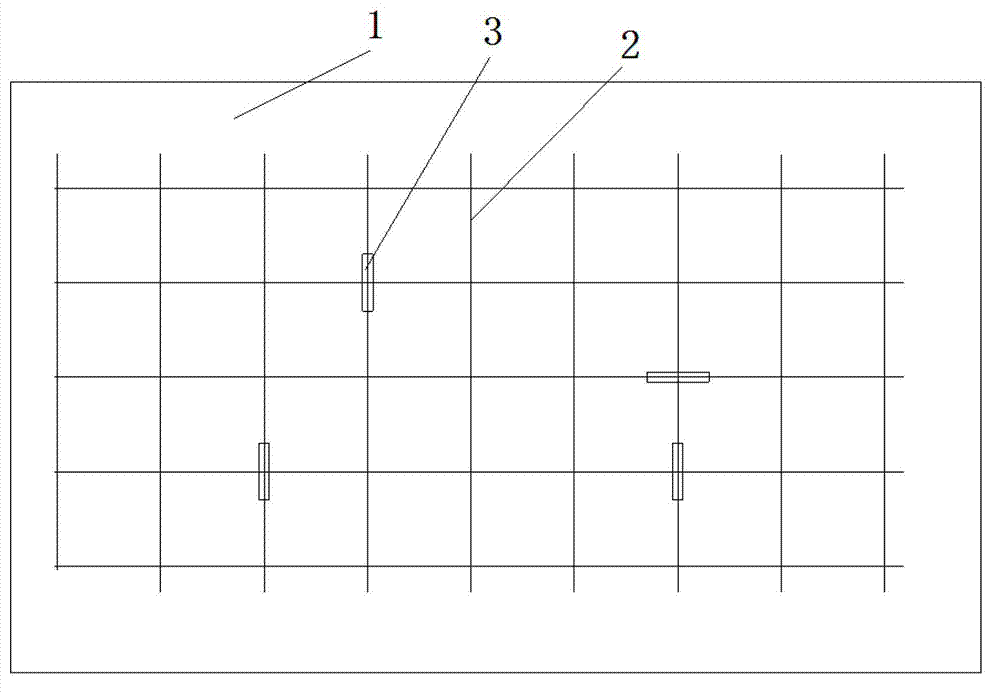

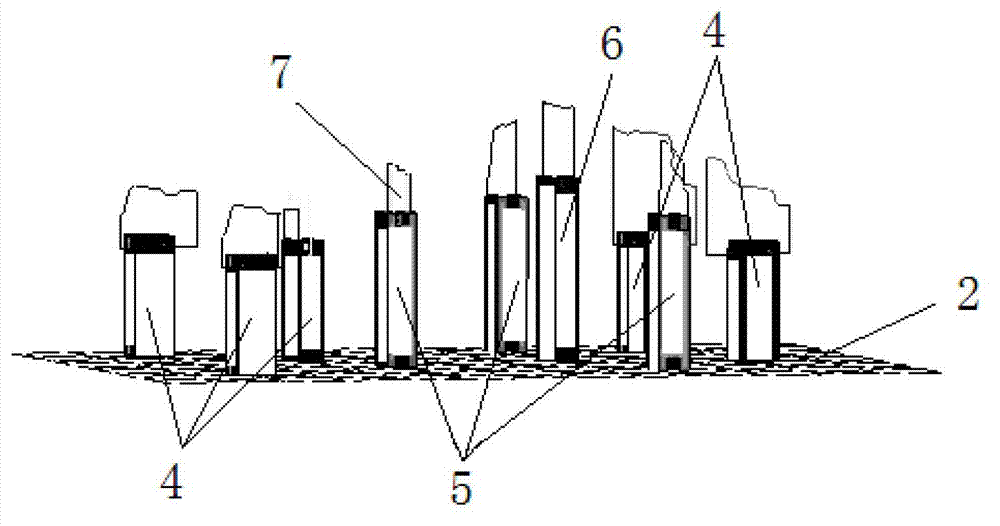

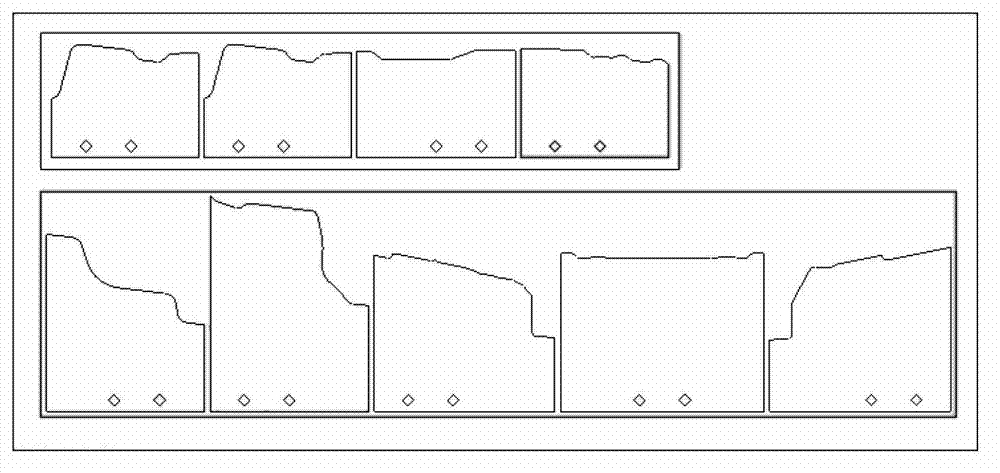

[0015] Such as Figure 1-2 As shown, a laser cutting positioning tool includes a workbench 1, unequal height support blocks 3 and symbol-shaped positioning brackets 7, and a rectangular grid line 2 is processed on the workbench 1, and the rectangular grid line 2 is composed of several hundred lines Connection composition. The unequal height support block 3 comprises five low support blocks 4, three middle support blocks 5 and a high support block 6, and according to the processing needs of the workpiece, the low support block 4, the middle support block 5 and the high support block 6 are set On the corresponding hundred lines, gaps are provided on these three support blocks, and screw holes are provided on both sides of the gap. Clamp and locate, then place the formed sheet on the symbol-shaped positioning bracket 7 for processing, after alignment, the program can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com