Laser device for cutting and method thereof

A laser cutting and laser technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of glass substrate cracking, cutting failure, crack growth and offset, etc., and achieve the effect of improving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

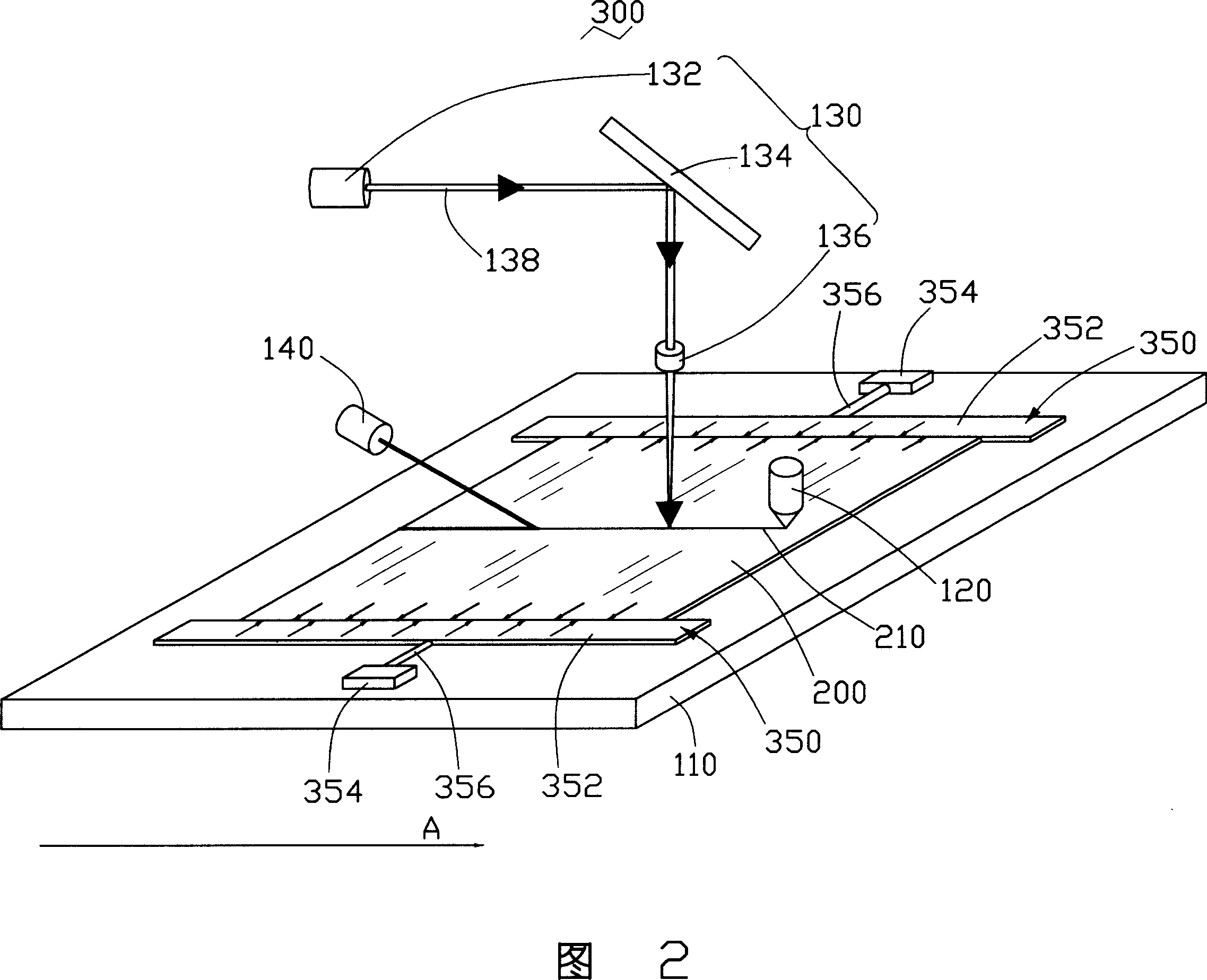

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

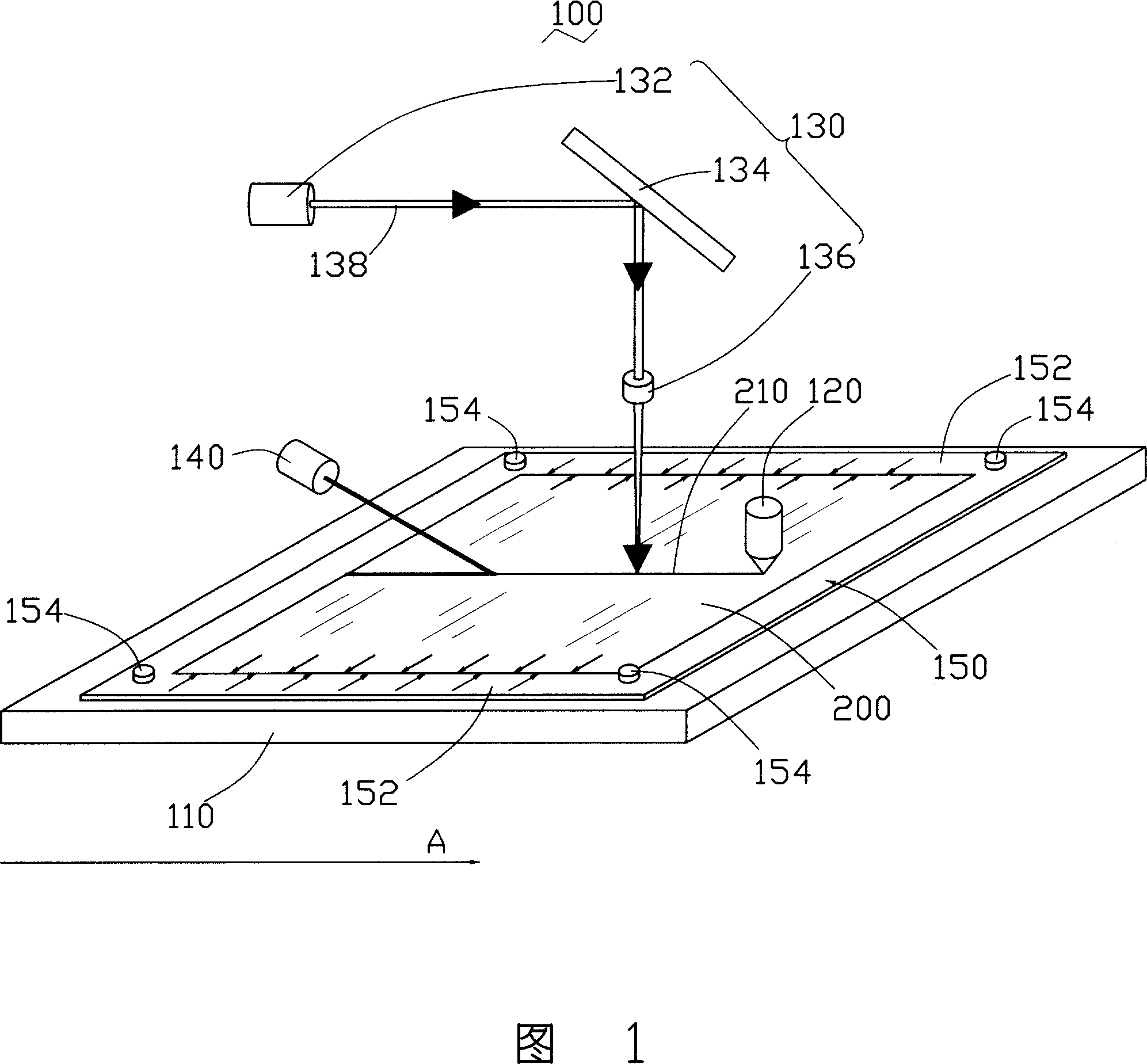

[0014] Please refer to FIG. 1 , the laser cutting device 100 provided by the first embodiment of the present invention includes a carrying device 110 , a cracking device 120 , a laser generating device 130 , a cooling device 140 , and a clamping device 150 .

[0015] The carrying device 110 is used for carrying the brittle material substrate 200 to be cut. The material of the brittle material substrate 200 can be a brittle material such as ceramics, glass or quartz.

[0016] The cracking tool 120 is used to form a pre-cutting line 210 along a predetermined direction A on the brittle material substrate 200 . The splitting implement can be a diamond knife or a knife wheel.

[0017] The laser generating device 130 includes a laser source 132 for generating a laser beam 138 to irradiate and heat the brittle material substrate 200. The wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com